In or Out? Where Does the Paper Facing of Batt Insulation Go?

If you install fiberglass batt insulation* with a kraft paper vapor retarder in a home, which way do you face the vapor retarder? To the inside of the home or the outside of the home? For many building science questions, the answer is, ‘It depends.’ For this one, the answer is clear.

SPOILER ALERT: The answer is right below this photo so if you’d rather wait and find out when you see the movie in the theater, don’t read any further.

The answer is that it doesn’t matter. Nope. You can install the paper facing however you want—as long as the building inspector† lets you, of course.

Why doesn’t it matter?

First, the kraft paper is a vapor retarder meant to reduce the potential for moisture problems caused by diffusion. Sounds like a good idea, but the vast majority of moisture problems are caused by air leakage, not diffusion, even in places like Maine. Do the air sealing; stop worrying so much about vapor retarders.

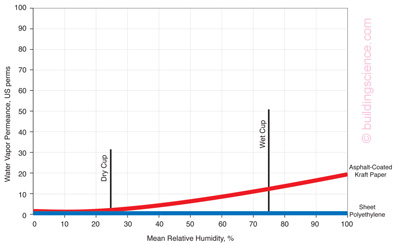

Second, if you install it the wrong way, it’s unlikely that you’ll have a problem. I suggest you read Joseph Lstiburek’s paper, Mind the Gap, Eh! The graph below, from that paper, shows water vapor permeance as a function of relative humidity.

As you can see, the permeance rises as the relative humidity rises and hits 10, the point at which we describe a material as vapor permeable, when the RH is 60%. The upshot here is that If you put the kraft paper on the wrong side and it gets wet, it won’t trap moisture. The wetter it gets, the better it dries. If you put it on the right side, where the humidity is, it’s not much of a vapor retarder.

Also on the graph is the permeance of polyethylene. As Dr. Joe says in the article, “Plastic vapor barriers really are vapor barriers when things get wet. Not so asphalt saturated kraft paper. And most walls with asphalt saturated kraft paper thank the building science gods for the difference.”

What about the advice to put it on the ‘warm-in-winter’ side?

If that really mattered, do you think the US building code would have dropped the requirement to use paper-faced batts? The warm-in-winter suggestion says that if you’re trying to limit the diffusion of water vapor, put the vapor retarder on the humid side of the wall, where…uh…it’s not able to retard much vapor.

In a really, really cold climate, it may matter, but even in Maine and Ontario, vapor retarder paint would be a better way to go. If you want to slow down the vapor diffusion, why not do it before it hits the drywall?

So just relax. If your building inspector wants you to put the kraft paper on the ‘wrong’ side, take another look at the graph above and be comforted that it doesn’t really matter. Then go get yourself some unfaced batts (and do your best to install them to Grade I quality).

~~~~~~~~~~~~~~~

*Speaking of fiberglass batt insulation, Carl Seville (a.k.a. the Green Curmudgeon) wrote another article on poorly installed batts recently, with photos of Knauf fiberglass. Rather than being a bully, like Guardian did to me a couple of years ago, they commented on the article and asked for a dialogue on how to get better installation in the field. Kudos to Knauf!

†My friend Abe Kruger likes to say that you should treat building inspectors like wild animals. You have to approach slowly and quietly because they spook easily. In the HERS rater class I taught in Toronto this week, I used that analogy but before I could get to the reason why they’re like wild animals, one of the students said, “You mean we can shoot them?”

~~~~~~~~~~~~~~~

Allison Bailes of Atlanta, Georgia, is a speaker, writer, building science consultant, and the founder of Energy Vanguard. He has a PhD in physics and writes the Energy Vanguard Blog. He is also writing a book on building science. You can follow him on Twitter at @EnergyVanguard.

Related Articles

You Don’t Need a Vapor Barrier (Probably)

Vapor Retarder? Vapor Barrier? Perms? What the Heck?!

Be a Controlling Building Enclosure Control Freak with Control Layers

~~~~~~~~~~~~~~~

Comments are closed.

This Post Has 19 Comments

Comments are closed.

In the Hot and Humid Climates

In the Hot and Humid Climates the paper goes to the outside (Hot Side) and in the north it is to the inside.

Abe: I love your analogy!

Abe: I love your analogy! Can I borrow it (w/ credit of course)?

Eric P.:

Eric P.: Don’t be afraid to read past the spoiler alert.

Dave R.: I sent Abe an email alerting him to your request.

Well this is an easy one. The

Well this is an easy one. The kraft paper should always be IN. As in, IN a garbage can where the fiberglass batt attached to it belongs. Stuff the can tightly, put the lid on and we have a perfect 6 sided air-barrier, surely this isn’t merely a coincidence.

Skylar S.:

Skylar S.: Judging by the installation quality of most fiberglass batts, that would be true. I’ve seen well-installed batts, though, so I know they CAN work…and not only when they’re IN the can, as you suggest.

Rare Grade I Fiberglass Batt Insulation Sighting

.

Thanks for the shout out,

Thanks for the shout out, Allison!

Dave: feel free to use it!

We have started instralling

We have started instralling over the stud face in PA and Nj on my projects. I noticed a differance on rough just before drywall. It was easier to keep the house warm in comparison to when we installed the staple tabs on the side of he studs. We first noticed in a 11’x12′ bathroom. we did the ceiling joist the same wal as the on top of the face of the jpoist and studs. we had a 500 watt flood light that over heated to room to the point we had to go get a coulpe of 60 watts buls to light the palceand not over heat it. this was before we understood or did the extra air sealing. we did have foam house wrap on the exterior with vinyl sidins like always. after that experience we not apply all batts with kraft face to the studs. I love arguements with the inspectors. I love askingthem to sign off that there way is better and won’t causea problem. they dpon’t ssign off and it get done my way. or I get the engineeer or architect to write the report and keep on file in the truck to remind the !@#$%^& everytime he pretents to know something about high effiecient home construction.

eric,

eric,

so in a hot humid climate batts are installed with faces stapled to outside of walls??

before blacking in the walls, you installl batts, then close in walls.

sorry, not how we do it in La.

Allison–a great article.

Allison–a great article. Well done.

To the La note above and Eric–it doesn’t matter where the paper is in the lower 48 states. Allison’s article is spot-on.

Thanks Alison <

Thanks Alison

Here in mixed climate mid-Atlantic, my preference is for a wall design with the following qualities:

– permeable both inwards and outwards for drying at both seasonal extremes

– rigid foam exterior to bring framing inside the thermal envelope- minimize conductivity

– avoid fiberglass altogether or unless one is confident of an air sealed cavity- as in flash and batt/ air-sealed drywall or similar.

– no kraft paper

– better yet- Larson truss or dbl framed wall.

– did I say avoid fiberglass?

I have a 2 storey home with

I have a 2 storey home with upper & lower heat pumps-how should I set both thermostats-It has a open foyer-I now have upper unit set at 65 degrees & lower unit at 70 degrees-not sure if this is most effective-also have gas fire logs I use -I use ceiling fan in lower great room in low winter direction-clockwise-

Allison — your comments

Allison — your comments about the irrelevance of the location of kraft facing on fiberglass batts are spot-on, and for all the reasons you iterate. You’ve added yet another nail in the coffin of the archaic kraft facing/retarder/barrier system.

But, just in case anyone still buys and uses faced batts, I’ll add two additional comments:

1) You CANNOT do a decent job of installing that which you can’t see. And that’s what’s going on when you attempt to hang faced fiberglass. The damn facing obscures your work, slowing down the installation and resulting in a poor insulation grade. Just buy un-faced batts, install them to Grade 1 and build your air and moisture control systems in another layer (big separate discussion).

2) I have over the years disassembled and remodeling thousands of residential buildings in Montana, all at 8000-9000 heating degree days. Many of these had faced batts installed in the building cavities, with facings installed in every imaginable configuration — up, down, in, out, torn, taped, stapled here, stapled there — and I have never ONCE seen evidence of moisture accumulation resulting from diffusion in these building cavities. It just does not occur. Lots of damage does occur of course from bulk moisture and air migration (another big separate discussion).

So I can agree with you with great certainty: The location of kraft facing is irrelevant because the entire system is an impotent, lousy, fake control layer anyway.

Abe K.:

Abe K.: You’re welcome, Abe!

Frank M: Side-stapling leaves that channel for air movement in each cavity, so what you found isn’t surprising. Of course, if air is moving in the cavity at all, it can move right through the fiberglass, too, so air-sealing is critical.

Debbie: I think the only way to do that effectively would be with modular homes, where they building inside out. The drywall goes in before the exterior sheathing does.

Wynn P.: Thanks! I appreciate that, especially coming from a fellow Summer Camper.

Robert P.: Drying potential is important!

Ron L.: I don’t think you’re posting your question in the right place.

Chris D.: Thanks! Great points about the problems with faced batts. And thanks, too, for the additional evidence of diffusion not being the problem, even in cold climates. Now, how you can stand to live in a place with up to 25 heating degree years of cold weather each winter is beyond me, but it’s good to have people willing to test the principles of building science in extreme climates. I like our 3000 HDD in Atlanta.

My answer: neither. &

My answer: neither.

The installers just use the paper to hide their bad installation behind. The paper looks perfect, but you reach behind it and there’s nothing there. I’m so tired of having to tear apart a whole house full of perfect looking paper to reveal the hideousness beneath. There is no way the paper confers enough benefits to make having it worthwhile in my climate, and the code doesn’t require it here either. I like to go paperless!

A few years back in my locale

A few years back in my locale (central Pa.)contractors were insulating then sheeting the inside of the rooms with plastic. I guess this was someones great idea on tightening of the house as far as infiltration. I’m not sure if this was a code and it was required or not I just know that they did it. I do know now that they longer allow this practices at all. I guess the principle was not to create a vapor retarder but vapor preventer. They learned through trial and errror as to what did happen. The plastic ended up condensing moisture on the backside. The moisture ran down the plastic and started rotting the treated base/sill plates out. Not a good scenario as this could lead to your prverbial black mold and such. Anyway I would have to say it would have to have been caused by air and moisture infiltration from the outside. Thus fitting in with the subject of improper air sealing. Thats my take. whats yours Allison?

Allison,

Allison,

Is the image in this article available for use? The Format Group would like to acquire permission to use it in a training manual titled Building Envelope Book 1: Principles by Carpenters International Training Fund.

Regards,

Brenda Wright

Permissions Liaison

This is not directly related

This is not directly related to this blog post, but….

What are your feelings on installing rigid foam board over existing kraft paper backed fiberglass insulation batts in knee walls? What about installing rigid foam board to the underside of rafters when the rafter cavities are insulated with kraft faced fiberglass batts? Do you believe that a moisture issue could be instigated between the kraft paper and the rigid foam board? Do you believe that it is necessary and more appropriate to remove the kraft paper backed insulation and install unfaced batts prior to the rigid foam board installation? We are assuming that the use of spray polyurethane foam insulation is not an option for one reason or another.

Thanks.

can you double up paper back

can you double up paper back insulation to fill deeper space by using 2 by 6 board studes as framing. Can I put the peper face against the outside wall and the second piece put fiberglass sides together, so the paper face of the inside paper is against the sheet rock.

I have been a drywall

I have been a drywall contractor for over 30 years and I can say unequivocally that stapling the insulation tabs over the studs (not to the sides of the studs) will cause the drywall screws to pop, if not right away certainly over time. The two staple tabs of insulation paper laid on top of each other to the nailing surface of the stud would seem to be an imperceptible discrepancy (perhaps a 1/16″ or less). However, stapling insulation in this manner creates and improper seating of the drywall during installation. This is in part due to the fact that insulation installed with its staple tabs to the stud face tends to “balloon” out of the stud bays making it harder to to get proper “seat” to the framing, for the drywall. Beyond “ballooning” even the small amount of paper tabs over the studs causes failed or not fully driven in screws. This is particularly the case at the corners where the drywall tends to be more fragile. Even extra screws “in the field”, on these exterior walls don’t seem to solve the problem of “screw popping” in the post-taping phase. Drywall is a finish product which one will look at for the duration of the homes existence. Lines of popped screws are highly evident once the walls have been painted and are not easily fixed. If there is no evidence of higher insulating performance by stapling the tabs to the stud face then put them on the sides of the stud in the stud bay where they belong. If there is evidence of higher insulating performance by doing it that way then perhaps it is time for some smart person to invent better insulation. Maybe sticky strip on the staple tabs that would adhere to the studs sides and create a better seal. ??? Thanks.