The 2 Main Problems With Kitchen Ventilation

Energy efficiency is a gateway drug to building science. When you really start learning about it, you come to the inescapable conclusion that there’s so much more to making homes better than just saving energy. A house is a system, you know. There’s moisture and comfort and indoor air quality and more. Today, let’s home in on the indoor air quality part, specifically as it relates to kitchens.

Indoor air quality in the home

I keep an eye on the work of some of the researchers who investigate indoor air quality: Dr. Brett Singer, Professor Jeffrey Siegel, Professor Shelly Miller, and Professor Richard Corsi, to name a few. One thing I’ve heard loud and clear from them and from the mechanical ventilation crowd (Dr. Joe Lstiburek et alia) is that the first step to good indoor quality is source control.

That can mean just not bringing in materials that are going to have a negative effect on the indoor air quality, like avoiding furniture made with materials that offgas urea formaldehyde. It can also mean attacking the source of indoor contaminants. A kitchen range hood does that by removing the harmful stuff that gets into your air whenever you use your range or oven.

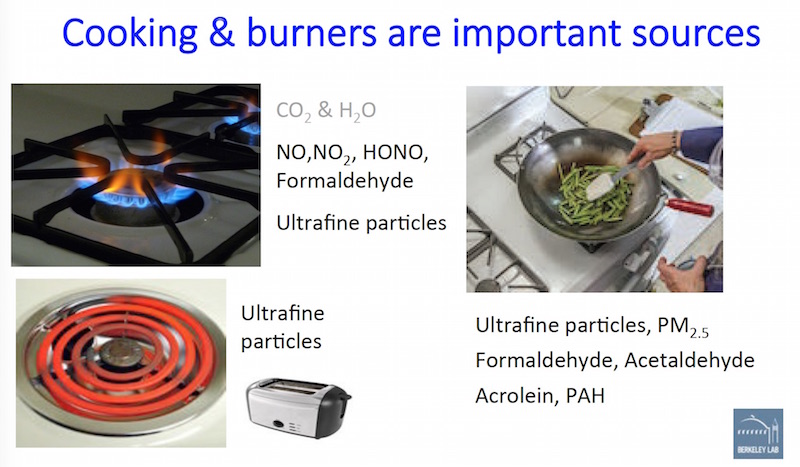

Last month at Building Science Summer Camp, Dr. Singer gave an update on indoor air quality in the home. Naturally, what happens in kitchens was a significant part of it. Here’s his slide on the contaminants that come from the cooktop.

As you can see, your indoor air quality is diminished not only by cooking but also by the burners themselves. Burning gas is the worst but those electric resistance burners put a lot of ultrafine particles in the air. The best way to cook if you want to minimize your impact on IAQ is to use an induction cooktop. Then you just have the stuff that comes from the act of cooking itself. As you can see above, that can be pretty bad.

In addition to those, I saw this tweet from Florida Solar Energy Center researcher Danny Parker:

Singer didn’t mention that on his slide, but if you check out the Wikipedia page on sulfur dioxide, it might help you remember to turn that range hood on every time you fry some up.

And that’s just what happens on the cooktop. If you have a gas oven, you could be dumping toxic levels of carbon monoxide into your air. I once tested a brand new gas oven and it spewed about 1,000 parts per million of CO at startup.

Clearly, the best solution for these poisonous and toxic contaminants is to get rid of them at the source. That means using the exhaust fan that you should have right there over the cooktop and oven.

And that leads us to the two main problems I promised in the title. They are:

1. Not using a kitchen exhaust fan

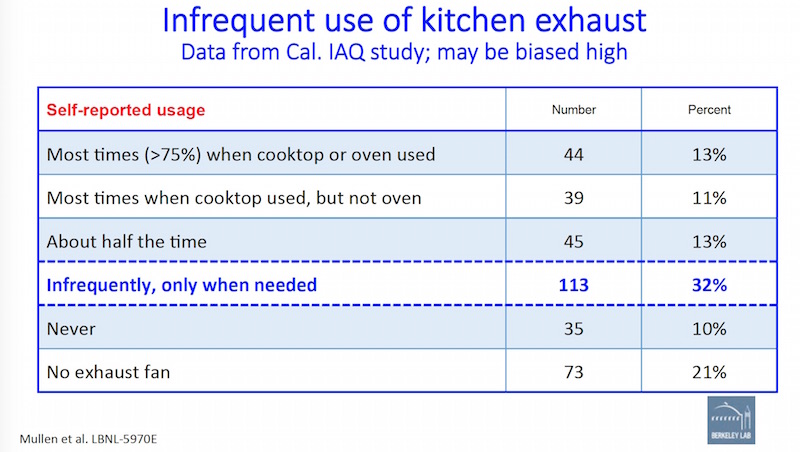

Most times people have the fan right in front of them when they’re at the stove cooking. Many of them fail to turn it on. Other times there’s not a fan installed. Yes, it happens. Here’s another slide from Singer’s presentation:

Only 13% of people in this study used the kitchen exhaust fan most of the time. Ten percent never used it and 21% didn’t even have an exhaust fan. Only about a third of the participants in the study used the exhaust fan half the time or more. The most common reason they gave for not using the exhaust fan was they thought it wasn’t necessary (48%). The next most common reason was noise (21%).

This is probably the easiest thing anyone can do to improve their indoor air quality. When you’re standing there in front of the stove, reach for the range hood switch before you turn on a burner or the oven.

2. An ineffective kitchen exhaust fan

Turning the kitchen exhaust fan on is a great first step in source control for better indoor air quality. But that doesn’t guarantee you’re getting rid of all the bad stuff generated on your cooktop or in the oven. Here are some of the reasons why it doesn’t all get sucked out of the house:

- The exhaust fan doesn’t vent to the outdoors – Yes, it’s true. Some are recirculating hoods that usually pull the air through a little filter and send it back into the room, often greasing your forehead on the air’s way back in. They’re standard in Passive House certified homes to prevent extra penetrations of the building enclosure, but in those cases, they still have kitchen exhaust via the ERV. (I still prefer direct exhaust ventilation from the hood myself.)

- The exhaust fan makes a lot of noise but doesn’t move much air – Bad ducting of kitchen exhaust reduces the air flow, just as it does with bathroom exhaust fans.

- The range hood has a low capture efficiency – Unfortunately, you can’t go out and comparison shop based on this metric. The researchers at Lawrence Berkeley National Laboratory, including Dr. Brett Singer, are spearheading this work. They’re not there yet but someday in the future you’ll be able to sort range hoods by color, size, air flow in cubic feet per minute, and capture efficiency.

What you can do to improve your indoor air quality

Kitchens dump a lot of indoor air contaminants into our homes. You can mitigate that by always using your kitchen exhaust. And if you’re in that group that doesn’t have any exhaust fan in your kitchen, get one installed as soon as you can. To improve your capture efficiency, cook on the back burner as much as possible.

If you happen to be building a new home or remodeling the kitchen in your existing home, make sure you put in a range hood, get one that completely covers all the burners, and ensure that the duct is sized and installed properly and vents to the outdoors. Oh, and don’t install a microwave with a built-in exhaust fan over the cooktop. Their capture efficiency is poor.

Finally, if your aren’t doing it yet, consider getting an indoor air quality monitor for your home. The Awair Element* is a good one that measures temperature, relative humidity, carbon dioxide, particulate matter, and volatile organic compounds (VOCs). When I bought a pair of them, the price was $149, but click the image below to get the current price. For carbon monoxide, the best tool is a low level CO monitor, not a UL-listed CO detector. For that, the Defender and the CO Experts versions are both excellent, and TruTech Tools sells both.*

Buy the Awair Element on Amazon*

The Awair Element indoor air quality monitor is one of the best tools for keeping an eye on how good—or bad—your IAQ really is and whether or not your filters are keeping the PM2.5 levels low enough. I have two of these monitors in my house.

Buy a low level carbon monoxide monitor at TruTech Tools*

Related Articles

A Pi Day Physics Lesson on the Induction Cooktop — With Dancing!

Recirculating Range Hoods — As Effective As Recirculating Toilets

An Update on the Residential Ventilation Debate

* These are affiliate links for Amazon and TruTech Tools. You pay the same price you would pay normally, but Energy Vanguard makes a small commission if you buy after using the link.

This Post Has 75 Comments

Comments are closed.

When you mention something as

When you mention something as “poison”, you aren’t being rigorous unless you discuss the dosage level. Plenty of things are toxic at one level, and insignificant at another. Some trace metals you cannot live without, are toxic if you get too much of them.

I think there is no substance that is not harmless at a low enough level of exposure. So really eggs, are they dangerous to fry?

Thank you.

Excellent point, Mark. A

Excellent point, Mark. A substance can be poisonous or toxic at one dose and not at some lower dose. It can still be labeled a poison, though. In his tweet, Danny Parker called hydrogen sulfide a poison. The Wikipedia page on hydrogen sulfide also calls it “poisonous, corrosive, and flammable.” I don’t know how poisonous frying an egg is but I’ll look for that Brett Singer reference on it. I imagine it would be a hazard only to the person standing there frying it.

In searching for a reference, I did find that it’s not just fried eggs that produce hydrogen sulfide. Nope. Boiling an egg too much will do it, too. (Click that link to see the article.)

Now, getting back to the dosage question, at his Building Science Summer Camp presentation, Singer gave this quote from Paracelsus that confirms your statement:

“All things are poison and not without poison; only the dose makes a thing not a poison.”

~ Paracelsus, 1493-1541

Interestingly, the German word for poison is gift. Monica Rokicki pointed that out on Twitter the other day.

OSHA exposure limits.

OSHA exposure limits.

https://www.osha.gov/SLTC/hydrogensulfide/hazards.html

Thanks for that link, Bill!

Thanks for that link, Bill! That’s helpful.

Good point Mark. The only

Good point Mark. The only issue I will take with your statement is there are certain elements in which the human body has absolute 0 tolerance for, and just an example of this would be Plutonium. However, that tiny detail shall not mitigate the valid, more important point you are trying to make. There is often way too much content on the web that suggests that something is bad at any level. It’s simply not true in an alarming number of cases. Water is actually toxic if the circumstances are right. In fact, one basic truth when discussing toxicity, is that anything that enters the body is toxic. But the body has highly complex systems in place to extract the necessary building blocks that support life, and discard the toxic stuff through 1 and 2. Additionally, if the body didn’t have other systems in place to deal with toxicity, we would all die almost immediately upon ingesting anything. That is a very general comment, maybe a bit too general. But I think the point is made. Bottom line, is there is an acceptable level of all kinds of what some consider cruddy stuff. Pardon the pun, but taking exhaustive measures to eradicate all levels of what someone considers bad, would actually be harmful in the right circumstance, all things considered.

I recently purchased a condo

I recently purchased a condo and have discovered that I have a ductless system. It is absolutely terrible. If you have the option, absolutely go the ducted route where the exhaust blows to the outside. I enjoy cooking and consider myself pretty decently skilled, but every time I use my stovetop, with the fan on, the smoke alarms in my condo go off. These systems are little more than a loud fan, swirling around the heat and smoke. I have been looking into options to convert my system to a ducted/vented system, but it appears that I do not have the choice due to my kitchen layout.

Danny Parker said frying an

Danny Parker said frying an egg releases hydrogen sulfide gas (H2S).

Then you Sulfur dioxide (SO2). These are different chemicals.

And I agree with what Mark said. The dosage makes the poison. The rotten egg smell (H2S) can be smelled by people well below the 1 ppm that hand-held equipment can detect at. The symptoms happen at higher levels and are typically from prolonged exposure. I don’t smell rotten eggs when I fry an egg. My exposure level to H2S is safe.

Thank you, Bill for your

Thank you, Bill for your rationality.

Allison thanks for this

Allison thanks for this article. It’s an important topic that’s just finally some of the attention it deserves. I set up the capture efficiency test apparatus at LBNL and did the first round of tests under the guidance of Iain Walker, Brett Singer, and Max Sherman. While there are no official capture efficiency ratings yet available for consumers, we did find clear trends indicating which types of range hoods are most effective. In addition to the great tips you give about not using microwave range hoods and using large, smooth, straight, short ducting, two other things I’d look for in a range hood:

1) a deep, open sump. A hood whose underside is shaped like an inverted bowl holds the plume in place so that the fan can pull it out. A flat-bottomed hood may look nicer, but it doesn’t do its job as well.

2) a centrifugal fan. They tend to be quieter and more efficient, and as you mention, one of the biggest impediments to people using their range hoods is the noise they make.

You’re welcome, Chris. And

You’re welcome, Chris. And thanks for adding those recommendations for range hoods. I just saw a conversation over on Twitter that showed one of those large flat-bottomed hoods and my first thought was about the extra air flow you’d need to pull everything into the fan.

Thanks for all this info. Can

Thanks for all this info. Can you speak to non external range hoods’ ability to remove grease from the air?

I don’t care about smell but I have a growing sticky grease layer on everything (I try to clean it off but it will eventually ruin everything I own) it builds up on ceiling fan blades then drops get flung into my wall!!

My condo association won’t allow new penetrations, or it’s going to be an uphill battle to try. I’m wondering if I can get something any size or height that recirculates and will get pretty much all the grease from the air. Cost is not an issue, I’m thinking around $1,000 but whatever works.

Any thoughts appreciated.

Thanks!

Thankfully I’ve seen more of

Thankfully I’ve seen more of them installed in new construction versus the typical microwave recirculating combo unit but still there’s a lot to be desired.

A couple of issues I’ve seen with range hoods:

As Allison already mentioned they are almost always too narrow (less than 6″ wider than the width of the cook surface) and mounted too high.

Never mounted on an exterior wall (shortest route to the outside). People seem to prefer windows over the kitchen sink which I can understand.

Mounted on an interior wall but with compromised duct design (i.e. rectangular “in-stud bay” duct or too narrow rounded duct with multiple bends/connections because ceiling floor joists are not orientated to facilitate a duct run with minimum turns.

Undersized fan. An undersized fan is usually not an huge issue if the capture area is large enough, but in almost all cases the capture area is too small.

All good points. Thanks, JC!

All good points. Thanks, JC!

Allison,

Allison,

Could you also address the make up air that is required for fans larger than 400 cfm? We no longer do new construction but when we did, it was always a challenge with the large commercial grade appliances in residential homes with 1,000 CFM blowers. Anytime you take that much air out, then its has to come back in and in southern climate that creates a myriad of other issues as well.

Thanks and love the blog.

The other worry with higher

The other worry with higher CFM fans is their ability to pull combustion gasses from open draft (or even direct vent) appliances. We’ve made typical open vent water heaters and furnaces spill by turning on a brand new gorgeous object-of-desire fan hood to the 200 cfm (middle) speed. At top speed (400 cfm) it was a disaster. And this fan in question had a makeup air vent nearby, which obviously wasn’t working. In our neck of the woods, I’d say we see open draft equipment like this in existing homes about 60% of the time.

Oh come on, Monica. Nobody

Oh come on, Monica. Nobody would put any kind of exhaust fan or appliance (e.g., clothes dryer) near a natural draft combustion appliance. Oh, wait… Unfortunately, this is all too real a risk. Exhaust fans and natural draft combustion aren’t friends.

Tyler, see Patrick Huelman’s

Tyler, see Patrick Huelman’s comment below and my reply to him.

If I understand capture rate

If I understand capture rate it is a measurement of how much of the contaminants are being captured. To give a capture rate, I would think you would also have to give a standard that might not actually apply to each application. Three variables I can think of are the distance above the cooking device (which often varies), the size of the cooking device (30″ wide? or 36″ or maybe even 48″?) and how tight the house is and is makeup air provided and if so, if what quantity?

Bob, I don’t recall the exact

Bob, I don’t recall the exact variables that LBNL has been using but it’s something like what you said. The test has to be standardized so you get to compare apples to apples, and that means that when you’re cooking oranges, YMMV. (That is, your mileage may vary.) I don’t think they’re considering airtightness or makeup air, though. They just make sure the range hood is moving the amount of air specified for the test.

Capture efficiency is exactly

Capture efficiency is exactly the problem that always gives me pause. Width of the hood side to side is easily managed but there is an implicit conflict between the depth of the hood and the height above the cooking surface. If the hood has sufficient depth to cover the cooktop and is installed low enough to effectively remove contaminants it’s likely that all but the shortest cooks are going to be suffering head injuries. And no, only cooking on the back burners is not a solution I’m prepared to offer my clients. I’d be interested if there is any work being done on backdraft and downdraft vents, I would guess the capture efficiency would be at the low end but I am always prepared to be surprised by actual data.

Most clients in any case are only interested in eliminating cooking odors, not contaminants and humidity, and when you tell them nothing short of a laboratory fume cupboard or cooking outside is going to do that they lose interest and either just go for the highest CFM available regardless of hood design or pronounce themselves in the camp of “Why even bother, I’ll never use it because they never work anyway”.

James, you’ve hit on a lot of

James, you’ve hit on a lot of important complications about range hoods that make it a difficult issue. Height and depth are critical, but maybe we just need to design them to have much greater area and sump (as Chris Stratton said above). Then they can be up high, which can work well in kitchens that are big enough.

I recall from Brett’s

I recall from Brett’s presentation at summer camp that the capture efficiency of the downdraft range vents didn’t seem comparably very good at all, especially on the front burners.

I had a downdraft fan –

I had a downdraft fan – Jennair. VERY disappointed in performance. It sucked the gas flame sideways making cooking very difficult and did not dispatch humidity from pasta pots or perform well in other respects. An over the stove vent was not allowed (I was in a rental) and realized exhaust was important, so this was my only option. Stove venting was run UNDER kitchen floor 10 feet to exterior – old farmhouse with high ceilings.

Make-up is very important

Make-up is very important complement to this conversation. However, the amount of make-up air is not solely determined by the rated flow of the exhaust hood. It is also dependent on house tightness and the level of negative pressure that is acceptable for that house. If you know both the fan flow and house tightness, it is easy to approximate the resulting negative pressure. But for make-up air sizing, it is common to work backwards. First, determine the acceptable negative pressure — actually that is the hard part. Next, based on your house tightness, you can determine the net flow that is can be exhausted so as not to exceed the pressure threshold that you have selected. Finally, you subtract that calculated flow from your fan’s rated flow and you will have the amount of make-up needed. BTW: I am ignoring the fact that the actual range hood flow rate may not be equal to the rated flow rate after installation or if is is subject to severe negative pressure. These items can be accounted for, as well, but require some additional measurement and steps.

Thanks, Pat. That’s a lot of

Thanks, Pat. That’s a lot of helpful information. Another part of it that you didn’t cover is where to put that makeup air. The ASHRAE handbook on HVAC Applications says to put only 40% in the kitchen itself. That keeps the pressure in the kitchen negative with respect to the rest of the house, keeping the contaminants that aren’t captured right away in the kitchen, to be exhausted with the makeup air from the other parts of the house as it gets pulled in there.

Huh, that is interesting, and

Huh, that is interesting, and probably something that many contractors putting in make-up air don’t do, out of ignorance but also out of a case of “the designer didn’t factor in locations for mechanical stuff and there are various cabinetry, window, framing, Homeowner Strong Opinions, or other obstacles that pretty much mean I’ve only go this one spot to put it.” And I also wonder how the 40% rule works with open concept kitchen/living/dining rooms?

I try very, very hard to get homeowners to use an induction cooktop and not put in a range hood over 400CFM, for precisely the reason of the cost and headache of putting in make-up air. I win that battle maybe 90% of the time.

Thanks Allison for that

Thanks Allison for that important addition. Not placing all of the make-up air directly in the kitchen also aids in how much and what type of tempering must occur. We must assume somebody with certain comfort limits or expectations is attending to the cooking. While not a direct energy issue, it perfectly reinforces your great intro to this story with “energy efficiency being the gateway drug to building science”.

Capture efficiency, if it is

Capture efficiency, if it is ever measured as a standard rating, will have to be be based on certain test bench conditions, just like the EPA mileage rates on a car. Nobody ever really gets that mileage, but it is a standardized measurement that lets you compare one unit to another.

Once you’ve picked your fan, installation and matching it to the range are certainly important variables. As mentioned above, the height, depth and width of the hood all matter. Local windspeed was not mentioned above, but is a potentially large issue. We’ve got a big, deep hood over our own stove and we use it. I have noticed that even a small fan circulating air in the kitchen can still blow quite a bit of the cooking smoke out of the fan. I’ve also seen this in hoods over kitchen islands, where someone just walking by the island moves enough air to interrupt the smooth flow from the stove to the hood.

I do like the idea of cooking in a science lab laminar flow bench, but for some reason, my wife does not. I don’t get it, but then again there are quite a few things I don’t understand.

All good points, Peter.

All good points, Peter. Especially about using a laboratory-grade laminar flow hood!

re: Best Practice

re: Best Practice Recommendations.

Allison: thx for highlighting this important info on healthy homes.

Your readers may also be interested in the 2018 Best Practice Recommendations for ducted range hoods at the ROCIS Range Hood link, http://rocis.org/kitchen-range-hoods. It addresses capture efficiency, low emission cooking practices, make up air, unvented hoods, and tools, based on research from LBNL, Europe, etc.

There is also a presentation from 2018.

I was the author of this material, with help from several expert advisors.

The HVI ratings for hood capture efficiency should be coming out around the end of this year.

There is also a Home Energy Pros forum on Kitchen Ventilation, that includes comments and newer info.

Here’s to Healthy, Low Pollution (HeLP) Cooking!

Thanks for providing that

Thanks for providing that link, Tom. Although I know most of the people in the acknowledgments, I wasn’t aware of ROCIS.

So where are the quiet,

So where are the quiet, automated range hoods? Installation and commissioning aside, it seems like at least half the problem would be solved by a standard for range hoods that are easy on the ears (honestly why does any company still make a loud fan), and that come on automatically whenever someone is cooking. I’m thinking an infrared sensor that kicks it on when it sees a >120F on the cook top would be worth a try.

I predict we’ll never really solve capture efficiency because even most build scientists probably don’t want to look at the ideal capture hood in their kitchen. But hey, if something’s got to do me in, let it be the smell of good cooking.

Also, my experience in testing various types passive make-up air for range hoods and water heaters is that it simply doesn’t work well enough to bother with. I plan on reading my way through the ROCIS stuff Tom Phillips linked to (thanks Tom) but I’d be curious if Patrick or anyone else has designed and tested effective passive make-up air. I like to see what it looks like. Per manufactures instructions these systems aren’t doing much at all.

And for that matter, where are the balanced range hoods?

Andy,

Andy,

I’m glad you brought up better rangehoods. Air King has recently introduced models that exhaust the kitchen continuously at sound ratings less than 0.3 sones so the homeowner may not realize they are on. They can be set for 30,50,70 or 90 cfm continuous and boost to 100, 200, or 300 CFM when being used as a rangehood. The RH doubles as the whole house exhaust fan to meet Ashrae 62.2 ventilation requirements. By exhausting continuously in the kitchen, even if the homeowner doesn’t turn it on as a RH you get some benefit, at least keep the contaminants in the kitchen area.

Additionally the home can be equipped with a filtered supply fan (Air King model QFAM or FAS) elsewhere in the house and you get a flow of filtered outdoor air from the supply duct to the kitchen to the rangeHood.

One problem not often discussed is that by installing the whole house fan in the living area you drag contaminants through the house to the exhaust fan. If you consider that many whole house fans are located in the master bath to save cost by eliminating 1 fan, you drag all the contaminants through the master bedroom where you spend (hopefully) 8 hours a night. Continuous exhaust in the kitchen is a far better solution.

John, do you have a model

John, do you have a model number for the new fans from Air King? Extremely interested in one of them but I’m having some difficulty in locating the right fan on the Air King web site. Thanks in advance and you make some great points.

try these links

try these links

Under Cabinet:

http://www.airkinglimited.com/page/energy-star-ECV-ASHRAE-hoods.html

http://www.airkinglimited.com/page/energy-star-ECQ-ASHRAE-hoods.html

Inserts:

http://www.airkinglimited.com/page/energy-star-power-pack-ASHRAE62.html

Please please PLEASE we need

Please please PLEASE we need automated range hoods! Infrared at a minimum, and maybe even some kind of interlock if we can. I hear commercial range hoods are required to interlock with the cooktop.

Seriously though, I can’t get anybody to use range hoods because of the noise… And even when they’re quiet, they won’t use the hood just out of habit.

Of course, not that I’ve seen any range hoods that work. My favorite was a cousin’s range hood – not a recirculating model – that he just ducted to the inside of the room. No charcoal filter, just the ductwork. We need stricter codes at the least, starting with remodeling, where people usually make kitchen ventilation worse.

If you’re talking about

If you’re talking about electric or induction stoves — $100 in parts will let you automate (interlock) any range hood capable of being fitted with ADA-compliant wall controls using a standard wall switch. The idea, though, is not sensing *heat*, but sensing *current* using a pair of RIBXGHA current sensors (one on each hot leg to the range/cooktop) calibrated using a pan of water on the smallest burner set to its lowest setting so that quiescent current (for the controls) doesn’t turn the hood on, while a RIBU1C relay turns the hood on based on the current sensor commands. If you want a wall override for the hood, that’s possible too — a Cooper 2225V or equivalent maintained-contact, center-off toggle switch can be used for the job, wired for on-off-auto functionality. (P.S. before you point out the RIBU1S, I know it exists, but having the override switch on the relay is rather…inflexible for residential applications.) One could conceivably do a similar thing using a flow sensor for a gas stove or cooktop, but I will leave that as an exercise to the reader.

Have your looked over at

Have your looked over at Building Science Corp ? There are a couple of good articles on how to commission a make-up air system for range hoods.

Range hoods are good and fine

Range hoods are good and fine for stove tops and ovens that are built into the stove. My problem is with wall mounted ovens which these days are all vented to the kitchen space. Short of making an outdoor kitchen, how can we ventilate these to the outside? Seems we have to enclose them within a closet and ventilate the closet to the outside. What was the reasoning for ventilating ovens to the interior space of the house? The manufacturers warn against having birds near the oven, don’t the designers have common sense and see that what’s bad for bird health is also bad for human health? This is the one thing i’m pissed off about the design of our new house…

To be clear I am not an HVAC

To be clear I am not an HVAC designer or contractor. However, since our program is deeply involved with tight houses, I have certainly studied this issue of make-up air a great deal. The bottom line is that the passive make-up air approach is pretty limited and doesn’t work very well, especially in tighter homes in a harsher climate. The hole or duct size becomes unwieldly and the tempering, when needed, is difficult. Keep in mind you are using the negative pressure created by the range hood to pull the air through the passive intake system. So let’s assume you can live with a negative pressure of 20 Pa for an hour or two (which at a minimum would require a sealed combustion furnace/boiler, water heater, and hearth products) and your resulting make-up air needed (fan flow rate less house infiltration at that pressure) is 200 cfm. If the passive make-up air system is 100′ equivalent length of smooth duct — which is reasonable with a hood, grill, a couple of turns, and probably a damper — the opening and duct size would need to be 8″ to get 200 cfm with a 0.08″ pressure drop. If using flex duct, best practice would suggest you go up one (or two) sizes. That’s a hard sell! And you still haven’t addressed the tempering issue. However, I am wide open to other’s thoughts and experiences on this increasingly important issue.

The solution is easy–don’t

The solution is easy–don’t fry anything anywhere (better for your health in more ways than one) and grill your meat outdoors. Everything else should be boiled (with a lid on it) or heated in the microwave.

Sorry Roy, not giving up

Sorry Roy, not giving up fried bacon even if it kills me. LOL.

Both my daughter and my best

Both my daughter and my best friend are afraid of microwave ovens. I use mine extensively and love and depend on it. Do you have any info on safety of using microwave ovens? I don’t understand their concern.

Good man, I agree with you. I

Good man, I agree with you. I am taking on the adverse effects of family members frying constantly with a cheap recirculating fan system (renting house). Um, if the kitchen and dining room is filled with smoke; obviously not working. Now I’ve been diagnosed with some form of lung blockage (COPD, Bronchitis, etc) after 10 ((5 years with son/then 5yrs with daughter and my mother)) plus years of complaining “I can’t breath” while they’re enjoying their fried food. I appreciate the great ideas I’ll want to implement when I finally buy a house. I really enjoyed the conversation. PS: You did state the option of grilling (frying) food outside (don’t have to give up fried bacon, which in itself can help kill you).

The design of chimneys for

The design of chimneys for open fireplaces is becoming a lost art, for many good reasons. Some of the principles involved however may transfer into a better understanding of contaminant extraction from a kitchen. Open fireplaces generally rely on passive convection to create air flow up the chimney, and the ratio of the open area of the fireplace to the size of the flue is critical – one reason why two-sided fireplaces are so hard to get to draw, and why cooktops in islands with free-standing hoods are unlikely to work well – ambient air can enter the catchment area of the hood from any direction and greatly dilute the extraction effort. I once designed a kitchen where at the client’s request the stove was located in a recess about six feet wide and two and a half feet deep with walls on each side that fully contained the cooking area. The hood was the entire ceiling of this recess dropped to a height of about seven feet with a bulkhead at the face dropping about eight inches lower. I suspect this arrangement constricting as it did the access of room air to the ventilation path would have captured more of the cooking smells, humidity and other contaminants than a standard open hood could ever hope to do, with or without makeup air. This arrangement was effectively a version of the traditional cottage inglenook where cooking was done on an open fire or if you were lucky a smoky old stove, and maybe it’s a configuration worthy of study for super-tight homes.

Hi James,

Hi James,

I’m a homeowner that is renovating a kitchen in a 200 yo home in NH … we are considering a very similar setup for our range to what you are describing within a 3-sided alcove (600cfm is recommended ventilation by range manufacturer) – I’m confused by the term “bulkhead” in your description, and generally would love more detailed info on creating such a system over our range. btw – we have both an open fireplace and a newer WBS in other parts of the house. HVAC is a combo of state of the art Mitsubishi ASHP and oil fired single pipe steam rads. Insulation is a combo of closed cell SPF in all attics and crawl space under kitchen to no insulation at all for double-brick original cape walls and rubble basement foundation (radon is a concern, too) … so creating negative pressure is worrisome and it is just plain confusing to know how to proceed. Thanks in advance for any info you could provide.

MY favorite dose kills story:

MY favorite dose kills story:

http://www.nbcnews.com/id/16614865/ns/us_news-life/t/woman-dies-after-water-drinking-contest

Finally the article I had

Finally the article I had been waiting for. As a homeowner obsessed with exactly this problem, and an ineffective 600 CFM rated hood, I want to make a few more observations on kitchen venting problems

1. The damper that’s built into the ductwork is usually not very tight (otherwise it sticks too easily in the duct boot). So I have a nice big hole there, turn on the leaky A/C to depressurize the house and I can hear the outside air coming in through the range hood (and smell whatever grease is accumulated on the range hood filter). Really interesting things happen when the exhaust port outside the house faces directly down towards the… the A/C unit!

2. The desirable laminar flow is easily disturbed even with good hood placement, says my rocket scientist friend. Eddie currents for one, and then there’s the cabinet and wall penetrations right above the range hood that builders may not bother to seal, being easy sources for some of the makeup air to be sucked down the top and front of the hood. If I slightly open a nearby window, my capture efficiency (and distance!) seem to improve, according to my Wizard Stick.

3. Hood manufacturers create unnecessarily fancy bottom plates for the hoods, what with downlights and heating lamps and switches and all, taking away from the capture area especially for the front burners. Could mounting it too high above the cooktop (because range hood specs want to protect it from excessive heat?) be counteracted by a few inches of a visor-like enclosure extension? A hood over the hood?

4. For some reason the range hoods are butted against the back wall even though they can be offset or mounted underneath cabinets above them. I would imagine capture efficiency wood improve if the capture area extended further forward – the back doesn’t matter if it’s against a wall, right?

5. A horizontally mounted fan motor seems to favor one side over the other (e.g. right over left) in terms of capture, so I must use not just any back burner but the right back burner for best results

I am excited about reading the excellent reference links provided by the commenters – will most likely lead to practical remediation ideas beyond my builder’s “there’s no problem, the system works well proven by the fact that it can hold on to a paper towel when turned to high” explanation

They make visor like

They make visor like extensions for microwave hoods, someone sells them on Amazon under the name “Microvisor-hood” or something like that. For proper hoods, it isn’t too hard to buy a sheet of stainless steel from McMaster-Carr, bend it yourself, and put some stainless steel sheet metal screws through it to fasten it. I’ve thought about this a lot, and I even use a rather large piece of stainless steel as a splatter shield when I search stuff.

I did not know they sell to

I did not know they sell to homeowners – will check them out.

I was even thinking I could use strong magnets to hold the extra sheet in place during use – and slide it back up later (or stow it away somewhere).

Awesome.

Awesome.

I believe that Fantech has

I believe that Fantech has addressed the kitchen exhaust issue very thoughtfully. They offer a group of in-line components including:

-Range Hood liner w/ fan speed control and lights that you can mount into a custom hood at any height

-Silencer which makes the system quite enough to actually use

-Remote fan which moves the sound source away from the range

-Backdraft damper

– numerous ancillary components

– make-up systems/components

The Fantech website doesn’t do a very good job of showing all the components in one place but hvacquick.com helps.

https://www.hvacquick.com/products.php/residential/Kitchen-Exhaust/Kitchen-Exhaust-Kits/Fantech-Kitchen-Ventilation-Kits

http://www.fantech.net/solutions/residential-kitchens/

hvaquick.com has links here:

hvaquick.com has links here: https://www.hvacquick.com/products.php/residential/Kitchen-Exhaust/Kitchen-Exhaust-Kits/Fantech-Kitchen-Ventilation-Kits

Including a kitchen info pdf: https://www.hvacquick.com/catalog_files/Fantech_Kitchen_Solutions_Catalog.pdf

This speaks to the need for a

This speaks to the need for a range hood solutions that have heat recovery in super tight houses. It seems pointless to build a super tight house and then dump energy through a direct-to-outside range hood exhaust system every time we cook something.

Is there not a way to integrate a range hood with a whole house balance ventilation system? I know there are fire and grease issues but it seems that technology should be able to find solutions for an integrated solution.

If seems that Zehnder has an integrated solution available in Europe: https://archello.com/product/zehnder-comfohood

It seems there is more work to be done on creating effective energy efficient ventilation solutions in North America.

Perfect is the enemy of good.

Perfect is the enemy of good. Install a hood or microwave and make sure the ducting is as free flowing as possible. Explain to the homeowner how important it is to use it, etc. This will take care of 95% of the issues. Want a low tech flow test for a vent hood? Take a 1/2 or 1/4 sheet of paper, turn on the hood and see how tightly the paper is held against it. Should be held pretty tightly, even on low. I realize this is subjective, however I’ve yet to see any properly installed Hood or Microwave not move plenty of air volume.

I agree ducting is important,

I agree ducting is important, but ability to hold paper against the hood doesn’t represent how well it will suck in smoke/heat/vapor/gasses from 30 inches away. Boiling some water on front burners and observing the steam get sucked in (or not) may be another low tech test. Capture Efficiency as a proper measurement would be nicest.

I agree however that would

I agree however that would require all the manufacturers agreeing on some sort of standard. A hood, any hood, seems to work better than a microwave over the range/cooktop. Most of my clients are middle income normal kitchens, so a high end expensive ventilation “system” isn’t in the cards. Everything is a compromise. Having something, and making sure the ductwork is optimal, is much, much better than no extractor at all.

All of this talk about how to

All of this talk about how to make a range/exhaust fan work well and quietly while there are hundreds or thousands of fume free extremely low db examples all over town. They are in restaurants where rooftop inline exhaust fans combine with powered makeup air and generously sized hoods to allow three foot flameups without a customer’s ears or nose ever realizing it. Yes they are commercial systems but we are installing commercial rangetops in homes. So lets study how Pei Wei does it just feet from their customers and scale it appropriately. A few ecm motors communicating to a current sensor on the range power should be more than possible.

Regarding makeup air:

Regarding makeup air:

Two years ago I was in Saudi Arabia, leading the design of a community of 300 new homes to be built at a university campus. I had the benefit of a team of mechanical engineers working with me.

They designed the homes to each have its own ERV (energy recovery ventilation) system, which ensured that the total air volume of the homes were refreshed regularly. Exhaust was pulled from kitchens and bathrooms and supply was into living and bedrooms. In addition, the kitchen hoods were tied into the system so that when operating they would trigger the ERV to provide fresh makeup air supply.

I would love to see this type of strategy in every new home.

Have you heard or read

Have you heard or read anything about a product called Plasma Made Air Filter? Their website is https://www.plasmamade.com/. I am concerned with IAQ and energy conservation and would to know if this product is useful or not. Thanks

This article and more

This article and more importantly, the comments bring up a lot of things to consider when choosing a range hood. However, now I don’t know what max cfm to get (knowing I’ll rarely use the highest setting). According to room size and btu output of my gas range, I require a maximum output of 720 cfms; nearly twice the 400 cfm another commenter recommended. I am also obsessed with lowest sones possible, and love the idea of continuous low speed ventilation that the air king models john fox mentioned. Not sure if I would have a problem with needing makeup air if I get a 750 to 850 cfm model; my house is older (1950s with fireplace that I don’t use). I would need an under cabinet mount with venting out the back side to connect to my existing ductwork. I have no working knowledge of this stuff – just a broken range hood and my friend google helping me out!

If you don’t use the

If you don’t use the fireplace make sure you plug the chimney with a chimney balloon!

Thanks for the nice article.

Thanks for the nice article. I just found it. Regarding the venting of inside air to the outside. In a house sealed up nearly airtight like my energy efficient home is, won’t the lack of a fresh air input limit how much air pollution gets removed from the house? I don’t imagine all the oxygen will be removed from the house, but I suppose a door or window should be cracked? But that would let in those little outside air particles that my MERV 4 furnace filter won’t clean out?

Does extraction hood increase

Does extraction hood increase the cooking time?

I was brought to this article

I was brought to this article while looking for an answer to a question I have not seen anyone else discuss: Why are there no ovens manufactured today that vent directly outside? This seems like a complete no-brainer to me–especially living in the southern U.S. where we desperately don’t want any heat at all coming from our kitchens nine months out of the year. Wall-vented ovens were commonplace decades ago; now we suck both cooking fumes and cooled air (that we just paid to condition) out through the vent hoods. Is it just me or is that rather inefficient? Why have manufacturers moved away from simply expelling the air through the roof or a wall?

I totally agree – have often

I totally agree – have often wondered about this myself. Many products appear to be “marketed” rather than featuring innovation. By this I mean, most manufacturers do not want to venture far from the features marketed by their competitors, perhaps fearing the increased price of additional features will eliminate their product from consideration. I have seen this approach in other fields. Perhaps it is also applicable to the field of ventilation?

Sadly this article was

Sadly this article was completely lacking in any technical depth. I came here to understand the best solutions for external ventilation design.

My engineer husband and I

My engineer husband and I took out the exhaust fan in an existing over the range microwave and installed ductwork from it to an exterior mounted tjerlund exhaust fan. It took some finagling including cutting, patching and painting sheetrock due to running ductwork and electrical wiring in between ceiling joists and cutting through an exterior wall but it is much quieter and removes much more of the cooking fumes than what had been a pretty lousy recirculating fan.

I need help because I’m a

I need help because I’m a carbon monoxide survivor. My detector ranges 1-8 ppm for CO. My toxicologist says it’s dangerous after already having. Any ideas? We currently have ceiling fan that vents outside but not strong enough?

My wife and I have a Zephyr

My wife and I have a Zephyr Hurricane fan that draws air from stove to above and then vents out above the roof. It is about 18 years old when we had it installed during a major remodel. My wife complains that it doesn’t seem to vent at all. We had it checked shortly after installation by the installer and he assured us that the installation and the vent pipe was done right. The fan also seems very noisy. When one buys this quality of fan — how long should one expect it to last? Do you think installing a new fan would help this situation?

I wanted to point out as you

I wanted to point out as you mentioned a reading of 1000ppm on startup of a new gas range that this would be normal on initial startup as there are lubricants and other chemicals that need to be burned off on initial start up… the same with a gas fireplace or furnace. However after the initial break in period a high CO level should not be an issue. Yes a fan should always be used when cooking, especially with gas cooking appliances and the are not vented otherwise.

I don’t have an exhaust fan

I don’t have an exhaust fan or range hood at all. I’m totally at a loss where to start. There is no duct work. House was built in 1953. No sure what to do. I make eggs often.

Will bugs be drawn into my

Will bugs be drawn into my house from my stove hood vent which blows out gas and other kitchen fumes to the outside of home kitchen wall?

I’ve recently had a large

I’ve recently had a large wood heater installed in my rural home in Australia. Whenever I turn my rangehood on in my kitchen (approx 5 meters away), smoke draws back into the house from the top of the wood heater flu. Opening my large kitchen window next to my rangehood reduces this slightly, but doesn’t eliminate the issue altogether. I’m finding myself having to cook on a gas cooktop without the rangehood going and instead use the window for ventilation, which isnt as efficient….nor does it help keep the house warm on our cold winter nights. With young children in the house i have concerns for what im exposing them to by not using a rangehood. Any ideas would be greatly appreciated.

Commenting again,

Commenting again,

Why do we keep letting buildings be built this way? Why can’t we improve codes to require outside, automated, hoods in new construction? Nearly every kitchen in NYC has no hood, or uses a recirculating hood. This is madness for indoor air quality.