The Best Velocity for Moving Air Through Ducts

The first thing to know about the velocity of air moving through ducts is that the slower you get the air moving, the better it is for air flow. That was the main point of my last article. In fact, the title asked the question, “Is Low Velocity Bad for Air Flow in Ducts?” And the answer was that, in terms of air flow, you really can’t get the air moving through the ducts too slowly.

But that’s not the end of the story. If it were, you’d always try to get the lowest velocity possible by using the biggest ducts that fit the space without blowing the budget. There’s another relevant fact, however, and ignoring it can lead to trouble.

Second Law troubles

In moving air through a duct system, we want good air flow but remember that the object isn’t just to move air throughout the house. It’s to move heated air in winter and cooled air in summer. When that conditioned air is moving through the ducts, the second law of thermodynamics comes into play because we have a temperature difference between the inside and outside of the ducts.

The second law of thermodynamics says that when you have objects at different temperatures, heat flows from the warmer to the cooler object. In winter, the warm air in our ducts can lose heat to the surroundings. In summer, the cool air gains heat from the surroundings.

And the amount of heat that flows between the duct and its surroundings depends on three things:

- Surface area of the ducts

- Temperature difference between the ducts

- Insulation level (as given by U, the heat transfer coefficient, or R, the resistance to heat flow)

The equation that ties these things together is:

Q here is the rate of heat flow and the units we use for it here in the US are British thermal units per hour (BTU/hr).

Heat transfer into moving air

As the conditioned air moves through a duct, it gains or loses heat in proportion to those three factors above. But that just tells you how many BTUs go into or out of the duct in an hour. The other factor is how much air is involved in picking up each BTU. The factor that governs this is velocity:

The slower the air moves in a duct, the more BTUs each cubic foot gains or loses.

And it’s not just time of contact that’s responsible. To get the air moving slower, we need bigger ducts so there’s more surface area, too. The upshot of all this is that when you’re sizing ducts, you have to consider the space those ducts are in.

If you put ducts in conditioned space, you can move the air as slowly as you’d like. When you put the ducts in an unconditioned attic and have the minimum insulation allowed, you want to move the air at a higher velocity, pushing it up near the maximum recommended by ACCA Manual D, 900 feet per minute (fpm) for supply ducts and 700 fpm for return ducts.

Mike MacFarland’s duct sizing tool

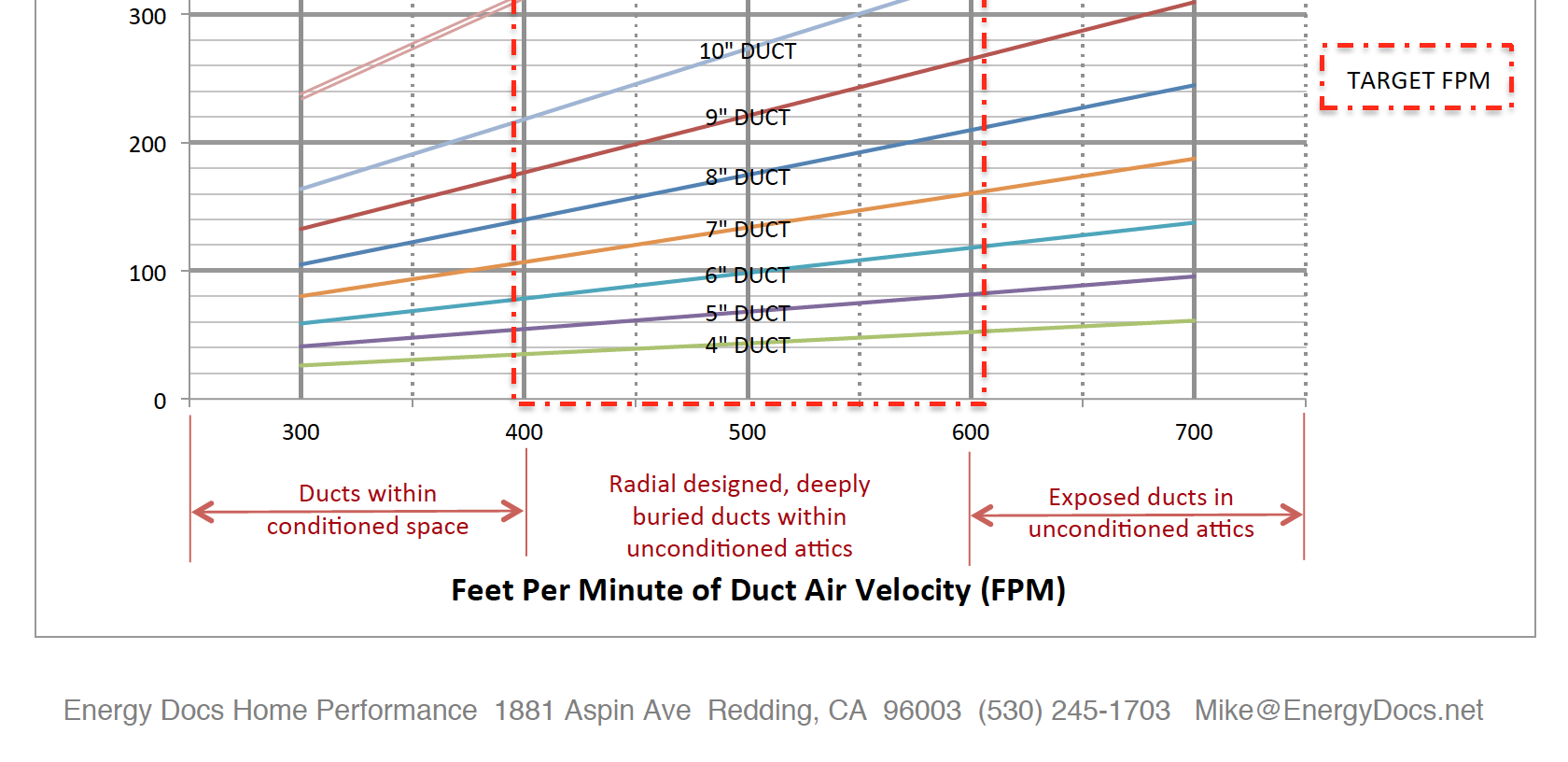

My friend Mike MacFarland of Energy Docs in Redding, California is a home performance and HVAC wizard. He knows the principles and has studied the research and he installs some of the best duct systems in the country. He uses the following ranges of velocity for ducts in different types of space:

600 to 750 fpm — Exposed ducts in unconditioned attics

400 to 600 fpm — Deeply buried ducts in unconditioned attics

Less than 400 fpm — Ducts in conditioned space

He put this into a chart that allows you to find the duct diameter that gives you the right velocity and air flow rate (cfm). The full chart covers duct sizes ranging from 4″ to 18″ and air flow rates from 0 to 1,200 cfm. (You can download the full chart by clicking on the image below or the link at the bottom of this article.) Here’s the bottom part of the chart, covering air flow rates up to 300 cfm:

If you need a duct to move 100 cfm, for example, you’d go with a 7″ duct if it’s in conditioned space, a 6″ duct if it’s buried deeply in the attic insulation, and a 5″ duct for exposed ducts in an unconditioned attic.

The takeaway here is that low velocity is great for air flow but sometimes bad for heat transfer. By selecting duct sizes that yield velocities appropriate for the conditions, you get the best of both worlds.

Download Mike MacFarland’s Duct Sizing Tool

Related Articles

Is Low Velocity Bad for Air Flow in Ducts?

The Invisible Problem With Duct Insulation

What Happens to Air Flow in Ducts When Size Changes?

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 25 Comments

Comments are closed.

Great article and very useful

Great article and very useful guidelines for considering supply and return air velocities! Thanks for writing it!

Other very important aspect

Other very important aspect is to maintain a certain minimum velocity of airflow at discharge grilles and diffusers to provide good throw of the air jets and good mixing of air in the room (which is another great topic for article).

Danko, that’s a great point.

Danko, that’s a great point. I mentioned that in the previous article, and there was a lot of discussion about it in the comments, too.

The key to this is when you

The key to this is when you wrote “If you put ducts in conditioned space, you can move the air as slowly as you’d like.” Get rid of ridge, soffit and gable vents. Seal the attic space off and insulate under the roof deck. If you use closed cell foam under the deck, you get the added benefit of increased structural integrity by “gluing the deck to the rafters/trusses. It also helps get blower door numbers like I do at .36 ACH-50. It is a win all the way around.

Thomas, yes, the first

Thomas, yes, the first priority should be to get the ducts into the conditioned space. Barring that, get them insulated as well as possible, by burying them in insulation if you can.

If I seal off my attic, and

If I seal off my attic, and my gas furnaces are also in the attic, where does the combustion air come from?

I just watched Joe Lstiburek

I just watched Joe Lstiburek’s presentation on YouTube “To vent or not to Vent”. I am reconsidering unvented attics.

Wouldn’t the dwell time in

Wouldn’t the dwell time in the attic pick up more heat with slower air flow

Bruce, yes, that’s why when

Bruce, yes, that’s why when the ducts are exposed in an attic and have the minimum allowed insulation (R-8 usually), you want to move the air faster.

Bruce, yes, that’s why when

Bruce, yes, that’s why when the ducts are exposed in an attic and have the minimum allowed insulation (R-8 usually), you want to move the air faster.

What about blowback from lets

What about blowback from lets say a bathroom exhaust/vent. Especially with the little port & small ducts their connected to with a turn or two in the line/path, exiting the building through the roof. Like to know how I came to this very interesting point on which no one makes no mention of! Go inside your bathroom, close doors leave them open it doesn’t matter. Light a cigarette & blow into the vent fan. You see your smoke being thrown back into the bathroom. Need to see it better, turn off lights light a candle, now watch your smoke as you blow it into the vent, some will leave into the vent but not all of it, as I pointed out before blowback will be seen more clearly with lights out, candle on & smoke source of your choice! If you have bends in the ductwork, the more air will be bouncing all over the place inside that duct. Air is not like water where water takes it’s course of path. The best way that I know to test for leaks but haven’t tried to put it to use in the ductwork system cause of the size, length is like checking if a water pipe has leaks, inhale while your thumb covers the bowl. Instant leak finder. Just hard to put it to practical use being that duct system are bigger & you’ll need a partner with a big enough thumb!

Blow cigarette smoke? That’s

Blow cigarette smoke? That’s horrible. Your human air ducts are infinitely more important than the ducts in your HVAC system. Please, stop smoking and try a better approach to duct and airflow analysis.

Does this chart assume flex

Does this chart assume flex or sheet metal ducting? Based on the performance characteristics of each material type, it seems there should be two charts, one for flex and one for sheet metal (also assuming nobody is using alumaflex ducting).

Brian, that’s a great

Brian, that’s a great question. The way we spec flex duct and the way Mike MacFarland installs it, there’s not a lot of difference between metal and flex. In fact, the research by Professor Charles Culp at Texas A&M showed that when flex is pulled tight with no longitudinal compression, the pressure drop is no worse than sheet metal. Here’s my article about that:

The Science of Sag – Flex Duct and Air Flow

And here’s what I wrote about flex duct a couple of years ago:

The Joy of Flex

An excellent article and

An excellent article and chart to teach the science of velocity vs duct loads vs fitting losses, etc. So now that we all understand duct design a bit better, time for a bit of reality.

Typical two-story home in my area, with a basement. Basement and main floor are served by the basement trunk. Upstairs has a chase to (sorry, the builder made me do it) the attic and the upstairs has insulated flex duct to the ceiling registers. So now you suggest a higher velocity in the attic is better?

I achieve higher velocity with smaller ducts and therefore smaller fittings. This 900 fpm design translates to even more resistance going upstairs than my normal 600 fpm design and my normal is still a challenge to cool the hot upstairs. Now more resistance is better? To me, this is the problem with most upstairs designs. Too far to go with too small of ducts.

And you will compound this problem if you now up-size to low velocity ducts in the conditioned basement. I see no air going upstairs.

Yes, zoning may help the comfort issue, but now the downstairs stat satisfies and I’m putting most of my air in a smaller duct to the upstairs, now my 900 fpm is up to… Too much!

I still subscribe to larger ducts in the attic (500 – 600 fpm) and simply adding a few seconds travel time and a little bit more surface area. My larger ducts help so many airflow resistance challenges.

Dan wrote “Yes, zoning may

Dan wrote “Yes, zoning may help the comfort issue…”

I don’t see how you can condition a 3-level home WITHOUT zone control. In fact, some jurisdictions now require equipment zoning or automatic air zoning in multilevel homes.

Your point about velocity with air-zoned systems is manageable. At worst, you size the upstairs ducts for a maximum of 900 FPM for single-zone calls. Of course that means lower velocity when more than one zone is calling, thus a bit more heat gain in attic runs during multi-zone calls.

The issue with satisfying a 3

The issue with satisfying a 3 level home is usually a. a design issue and b. an installation issue. Ducts can and will carry the right amounts of air to the required space if the design is accurate and based on design conditions. Secondly, if we call for a 4″ round and you put in a 6″ that will change the air flow of the design. And frankly a 4″ piece of round won’t fit into a 2×4 pocket, so that needs to be addressed as well; carpenter issues or switch to oval as examples. But we as an industry can’t change the design without consequences. Thanks for the great article and helping my compatriots to understand air flow.

Although not related to

Although not related to velocity per se, it bears mentioning that the A (area) in the heat transfer equation is not just a function of a duct’s cross-section but also of its length. Short branches to interior walls go a long way to minimize unwanted heat transfer in ducts routed through unconditioned attics. In fact, if branch runouts are short enough, a duct can be increased by one size with minimal impact on surface conduction.

The important message here is that designers should be aware of all these trade-offs and know how to estimate the impacts as they work toward an optimal design.

Much appreciate this and the

Much appreciate this and the other arrivals you put together. I would be curious to get a DB rating effect and Mikea opinion for the various velocities in unlined sheet metal. On a side note, as a big hydronics junkie, the size of ducts in conditioned space at that slow of a velocity means huge ducts, and enforces the need to transferring the BTU through water pipe rather then air pipe.

So, my ductwork is in my

So, my ductwork is in my attic, and may be about to be joined by my air handler. I’m in north Texas, where the attic gets pretty hot, especially in a 1980s house with no radiant barrier, and lousy insulation.

But I don’t really want a huge amount of noise from my ducts, plus that whole article about the effective length goes up as velocity increases.

If I surround, at least my main rectangular ductwork with R-45+ foil-faced polyiso rigid insulation, am I at least minimizing the effects of my hot attic on my ductwork?

I agree with many of the

I agree with many of the overall conclusions, but I do have to nitpick about some of the specifics. Let’s start with Q=UxAxDT. If you decrease the air velocity, U also decreases. Why? Because U includes the convective resistance of the indoor air stream, and it goes up as the air velocity goes down. Thus, the overall R-value of the duct (wall insulation plus surface convective resistances on each side) goes up with decreased air velocity, but this effect is small compared to the wall resistance if you have insulated ductwork. Thus, I disagree with Allison’s statement that “The slower the air moves in a duct, the more BTUs each cubic foot gains or loses.”, if you are talking about per square foot of duct surface area. The dominant term in the above equation is area (A) which is the duct surface area. To reduce air velocity for a given fixed airflow rate (cfm), you do have to increase the duct surface area significantly. That is why duct heat gain or loss in unconditioned spaces goes up, even if U goes down with higher duct air velocities.

As for air “residence time”, that has no direct influence on duct heat gain or loss. I don’t know where that term started, but it is meaningless to me.

Take my house, built in the

Take my house, built in the 1920’s, frame made of Redwood, I’m located in L.A./OC area of California. 1 story with a attic and 3 gable openings & crawlspace. Heating furnace with duct branches in a uninsulated attic. Now when the heat hits dry heat is bearable, house cools a couple hours after Sun goes down. When it’s humid the house is like a oven after 3pm. The house does not cool till after 12am & all the hot air in the attic goes nowhere but down the side of the walls & out of every open surface available. At times it gets so humid I feel the heat is coming from the ground, I understand where on a living organism that’s needs to breathe too, especially when where suffocating it with concrete & asphalt all over this God given land. At times the red brick is cooler than the concrete & the freeway concrete gives off an extremely hotter amount of heat, being surrounded by it in the big city. There’s a lot of factors that play in my part. My point is that hot air in the attic goes nowhere but down & all around inside the house, even if there’s a cool breeze & clouds that came out of nowhere on which was a 95 degree day at around 4pm late afternoon in which the day was humid. The humidity left for a couple hours, but later after 9pm returned for the rest of the week. No I don’t have any venting in the attic nor soffits or wind turbines. I know, but getting your grandparents to understand what needs to be done is like teaching that old dog new tricks, some dogs don’t even listen to you!

How can I tell if a duct is

How can I tell if a duct is poorly made? I have a subcontractor installing ductwork that he sealed with non UL listed tape and now I am examining everything very closely. Just stuck my head in a plenum and it seems very sloppy to me. He has installed insulation on the outside so I cannot tell if the seams are properly sealed. I asked him no to install the insulation before I inspected the seams and he packed up and left the job. Ugh

I hate to be the bearer of

I hate to be the bearer of bad news but all seams (including boots) should have been sealed with duct mastic, not tape! Even the best tapes will eventually lose adhesion (faster if located in attic or crawl).

Without a written contract that calls out this detail, your only recourse may be the building code. So check with your building inspector before doing anything else. For example, some jurisdictions require mastic instead of UL-181A-P tape on metal seams. Likewise with your requested pre-insulation inspection. Unless you put it in writing….

As for evaluating the ducts, most jurisdictions now require a duct leakage test (unless ducts are fully within conditioned space). Either way, I recommend that you have the ducts leakage tested by an energy auditor or HERS rater.

If the ducts are all (or mostly) metal, removing & replacing all that insulation may be cost-prohibitive, assuming you have no recourse with the installer. If ducts are inaccessible, there’s a technique called AeroSeal that seals ducts from the inside, but it’s expensive. Perhaps even more than removing and replacing the insulation.

I like your article, as it

I like your article, as it gets across an important point about thermal versus fan energy issues. I would however not say: “If you put ducts in conditioned space, you can move the air as slowly as you’d like.” If you slow things down too much, the thermal losses defeat the purpose of the the ducts, which is to get the heating or cooling distributed to particular rooms. I am currently analyzing ducts in conditioned spaces more carefully, but have done detailed experiments on the interactions between ducts and variable capacity heat pumps. I would be happy to share those if you would like.