How Many Tons of Air Does Your HVAC System Move?

We live in this invisible stuff called air. (But of course you knew that.) We pump it into and out of our lungs. We exhaust it from our bathrooms and kitchens. We cycle it through our heating and air conditioning systems. If we’re lucky, we live in a home that even brings outdoor air inside as part of a whole-house ventilation system. But we’re missing something.

Air seems insignificant. Even though we’re immersed in this fluid continuously, it seems to have no substance. After all, we move through it without noticing it most of the time. But air really is quite substantial. It has weight. It requires work to move it around. It takes energy, even when we’re not heating or cooling it.

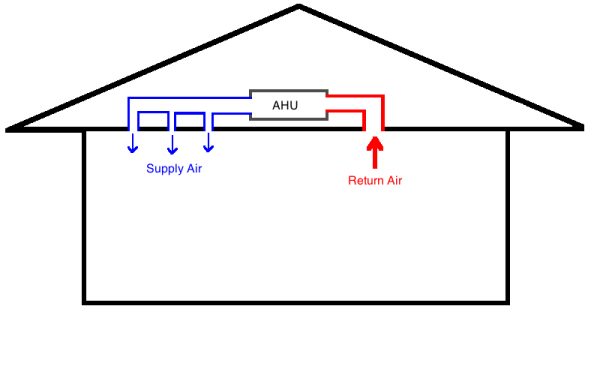

Let me see if I can help you get a feel for the weight of air. If you live in a home with a forced air heating or cooling system, that system has a blower. The one shown above is typical. It pulls air through the return ducts and into the furnace or air handler. There, it does its heating or cooling magic and sends the air on its merry way back to you through the supply ducts.

A fairly typical size for a blower is one that moves 1,000 cubic feet per minute (cfm). How many pounds of air would it move in a day if it runs continuously? Before you scroll down to look at the answer, though, really think about this. Come up with a guess in your mind. How many pounds of air does your air handler move in one day? Write it down.

Got that number? Well, let’s find out how close you are. We just need to do a little bit of easy arithmetic.

We may as well begin with volume. If our air handler runs every minute of the day, that would be:

Run time = 24 hours x 60 minutes per hour = 1,440 minutes per day

So how many cubic feet of air does our 1,000 cfm blower move?

Daily volume = 1,000 cubic feet per minute x 1,440 minutes per day = 1,440,000 cubic feet per day

A cubic foot is about the size of a milk crate. Imagine nearly 1.5 million milk crates of air going through your air handler in one day!

So what’s the weight of that 1.44 million cubic feet of air? We need the density of air to find that number. As it turns out, the density of air varies. It changes with your location on the planet. It changes with your height above (or below) sea level. It changes with temperature. It changes with humidity. It changes with… Well, you get the idea.

Let’s take a number at sea level that’s a pretty good average density for air. And let’s make it easy by using only two significant figures:

Density of air = 0.075 pounds per cubic foot

Now it’s easy to see the last step.

Daily weight = (0.075 pounds per cubic foot) x (1,440,000 cubic feet per day) = 108,000 pounds per day

We have an easier unit to use when we get up to that many pounds, though. Let’s convert to tons:

108,000 pounds per day ÷ 2,000 pounds per ton = 54 tons per day

And there we have the answer to our title question. Well, we have an answer that corresponds to the assumptions we made anyway. The biggest one is the number of hours per day the system runs. If yours runs continuously, you’re probably wasting energy and possibly turning your house into a mold factory.

If your system runs half the hours in a day, though, the result would be half the number we got above, 27 tons of air per day. Even if your system runs only 15 minutes each hour, or 25% of the time, your system would still be moving over 13 tons of air per day. (Of course, you know that we’re talking actual tons here and this has nothing to do with the tons of cooling capacity of your air conditioner.)

This little exercise should give you more respect for air now that you know how much weight it carries.

Related Articles

This Thermostat Setting Can Cost You Money and Make You Sick

Why Is Air Conditioner Capacity Measured in Tons?

Don’t Set Your Air Conditioner Thermostat Like This

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 7 Comments

Comments are closed.

I live in Oklahoma. We get a

I live in Oklahoma. We get a lot of tornadoes here. Last weekend, one missed our house by a few miles and hit the local casino. (Perhaps I live right!) The damage was minor, but it was only an F1 tornado. So yea, I am aware of the “weight” of air.

It’s kind of amazing that we can move that house air with a half-horsepower motor, but we are only “lifting” it by about an “inch” (of water).

Glad to hear the tornado

Glad to hear the tornado missed you, Roy. That kind of air movement gives a whole new meaning to weight of air.

At the beginning of the article, I mentioned work and energy but didn’t explore that topic further after the calculation. Of course, anyone who’s been through an introductory physics class may recall that it’s possible to move things with weight with no expenditure of work or energy. As long as you move it horizontally and with no friction, you don’t have to do any work. But if we have to push air through ducts that have friction or if we have to push it up from the basement to the first or second floors, then we have to use some energy to make it happen. Now, if someone will invent frictionless ducts…and then not do stupid things with them.

When I said “lift” the air 1

When I said “lift” the air 1 in of water, I used a bad metaphor. The ideal power required for a blower or fan to move air is the volumetric flow rate multiplied by the pressure rise of the blower with some appropriate units conversions. If you multiply 1000 cfm by 1 in.w.c. for a typical residential blower to overcome the coil, filter, duct, etc. losses, the ideal power is about 120 W. Note that the density is irrelevant! A real blower requires 3 to 4 times that amount due to blower and motor inefficiencies (overall efficiency of around 25 to 33%). As for temperature rise through that same blower, it would be about 0.4 F for an ideal blower and 3 to 4 times that for an actual blower and motor. By the way, I learned this in my engineering classes, not my physics classes 😉

So unless I slipped a decimal

So unless I slipped a decimal, one cubic foot of air weighs more than one ounce! I never suspected. Thanks.

Allison, a question.

Allison, a question.

To what extent does energy expended by a typical PSC fan change the temperature of air moving through an HVAC system?

“It depends” is not an acceptable answer. 🙂

Steve Waclo…about 1.6F

Steve Waclo…about 1.6F

This is a great conversation

This is a great conversation to have. As you have mentioned several times, there are many other variables to moving air. One of the things mentioned is that by running a 1,000 cfm blower continuously, you are “probably” wasting energy and “possibly” creating a mold factory. But what about the positive side to running a blower continuously?

First and foremost, duct sizing must be proper for the system. Secondly, I only recommend constant air flow when an ECM motor capable of having the volume of air reduced dramatically during times when the system is not calling for cooling or heating. Now we have totally different conditions for moving the same air. These differences alone, and you know there are many others, “can” reduce energy usage due to reducing system cycles and “may” reduce humidity conditions that cause most issues with mold if that ECM blower is a variable speed controlled model that is set up to utilize less volume of air during calls for cooling. Less air, colder coil, more condensing of moisture in the air; greatly offsetting condensate blow off conditions that may keep humidity levels higher with the use of a PSC motor. As for the mold? Mold is in the house no matter what. If we have any chance of reducing mold spores in the home it is by filtering it out of the air. Air filters, as all IAQ products, only work when the air is moving through the system. This is especially important for home that have attic cooling systems that are not used for heating during heating season. That is when moisture collects in the ductwork in the attic, condensing in low lying ducts and making for a wonderful place for mold spores to grow.

Then there is the comfort factor. When there is a constant movement of air, preferably low enough velocity that it is not even noticeable, there is less stratification of heat in multi-level homes. My home in the very humid but not really that hot Mid-Atlantic area of the country has a heat pump system that is designed to operate with a nominal 1,000 CFM of air in the cooling mode. There are two levels to my home with a bonus room with a vaulted ceiling, so I have a variety of conditions in my home. By operating my system in the cooling mode at 700 CFM with a Variable speed blower motor, along with the use of a properly metered but otherwise oversized indoor coil (rated at 4 ton nominal for 13 SEER ratings), my system reduces moisture in my home very well when in the cooling mode. By leaving my blower set to constant on at 30% of cooling capacity when the system is not calling for cooling, my filtration and UV light system are in constant operation and the temperatures do not vary from one part of the house to another. By setting up the air movement in this way, even though I have technically reduced the SEER “rating” of the system, my energy costs are slightly lower, my humidity levels are much lower and my comfort level is about as good as anyone could expect.

I merely wanted to point out that we need to take each specific application into consideration before being negative about constant air flow in HVAC systems. My set up is obviously not for every application, but in my area of the country it more applicable than not.