The Unintended Consequences of High-MERV Filters

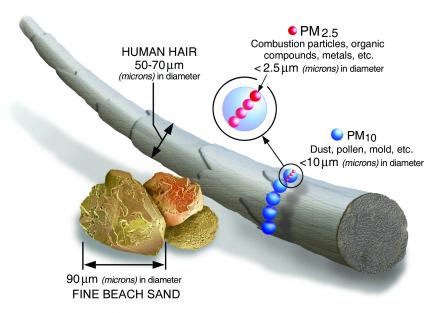

What is a hair’s breadth? A strand of the finest human hair is about 20 micrometers (also called microns) in diameter. Take a piece and slice it in half. Then take one of those halves and slice it in half again…and then one more time. Now you’ve got a sliver of hair that’s 2.5 microns wide. Officially, 2.5 microns is 0.0000025 m, or 2.5 µm. If you must, that would be about 0.0001 inch. Whatever units you use, though, it’s a really small size.

Fine particulate matter and filters

That also happens to be the size of particulate matter that causes a lot of indoor air quality problems. Last month I wrote that fine particulate matter is the really bad stuff. Fine particulate matter is also called PM2.5 because it’s the same size as that superfine hair sliced in half three times. It’s 2.5 µm or smaller.

The size is important because really small things can get into places that bigger things can’t. Like deep into your lung tissue, where it can find its way into the bloodstream. And that was the point of my article on which indoor air pollutants are of most concern.

But you’re in luck. As it turns out, the PM2.5 particles can be filtered out of the air with the right type of filter. After my article on indoor air pollutants, I wrote about filters and even included a nice chart from my friend John Semmelhack. It shows the percent of different size particles trapped by filters with different MERV ratings. The chart shows that to remove at least 85% of the PM2.5 from the airstream, you have to use a MERV-13 filter.* Of course, you should read that whole article because I also talked about a lot of reasons why you may not be getting the filtration you think you’re getting. You may know this already if you’re monitoring your indoor air quality. (And if you’re not, the Awair Element* is one of best, and most affordable, IAQ monitors for homes.*)

Today, though, we’re going to home in on just this one issue of upgrading to a filter with a higher MERV rating, a filter that can remove more of the small stuff. First, we’ll take a quick look at what MERV is and then some of the potential problems with using high-MERV filters in your heating and air conditioning system.

What is a MERV?

MERV stands for Minimum Efficiency Reporting Value. It’s an acronym created by ASHRAE to provide a scale showing the effectiveness of filters at removing particles of different sizes. The range of sizes in the MERV scale is 0.3 µm to 10 µm, subdivided into smaller ranges.

For example, to achieve MERV-13,* a filter has to catch 90% of particles in the 3-10 µm range, 85% of particles in the 1-3 µm range (where PM2.5 is), and 50% of particles in the range 0.3-1 µm range (the really, really small stuff).

In general, filters with higher MERV ratings catch higher percentages of particles as well as smaller particles. And MERV-13* is pretty much where you want to be.

What could go wrong?

When you put a filter in the airstream, the air has to go through it. (Unless you have bypass, but you’re reading this so I’m guessing you already know to use a good filter cabinet and install the filter in it properly.) Going through the filter material, the air encounters resistance.

How much resistance depends on the type of filter material and the amount of area. The standard fiberglass filter doesn’t resist the air flow much, at least not when the filter is clean. As the filter loads up with the stuff it catches, the resistance increases.

If you want to remove more stuff from the air, you can use a filter with a different material. The pores in these filters are much smaller, allowing the filter to catch more pollutants from the airstream but also adding more resistance. The higher MERV filters have higher resistance.

When you add more resistance, you can get a bigger pressure drop across the filter. And that’s where the problems begin. The blower in the furnace or air handler is rated for a certain amount of pressure drop. If you use a lot of it up just to get the air through the filter, there’s not much left to move the air through the rest of the system.

When the pressure in the duct system goes up, it’s possible that the blower will use more energy. Paradoxically, that happens with the more efficient blower motors (ECMs), and not so much with the less efficient PSC motors. (OK, OK. Here’s what those two things stand for: ECM = electronically commutated motor; PSC = permanent split capacitor.)

And that brings up the next problem: reduced air flow. If your system is rated for a total pressure drop of 0.5 inches of water column (i.w.c.) and you use up half of it just at the filter, you’re not likely to get the amount of air flow the system was designed to deliver.

One consequence of low air flow is reduced comfort. In the hottest and coldest weather, your system may not be able to deliver enough heating or cooling to the house. Or it may just be one or two rooms that get uncomfortable.

Another consequence of low air flow is that the air conditioner coil may get too cold and even freeze up. That starts a vicious cycle of lower and lower air flow and a colder and colder coil until the coil is just a block of ice. Then the refrigerant doesn’t evaporate and goes back to the compressor in the liquid state, which can damage the compressor.

Same thing can happen with a furnace. Low air flow means the furnace heat exchanger gets hotter. It could even crack. If that happens, your duct system can become a carbon monoxide distribution system. You’ll sleep well…but you may not wake up.

But there is a positive consequence that comes with low air flow, too. In a humid climate, the air conditioner will dehumidify better. That’s only a benefit as long as the air flow isn’t so low that it turns the condensate to ice.

To summarize, a high-MERV filter can:

- Add resistance to the air flow

- Increase the pressure in the duct system

- Increase the energy use of the system

- Reduce the air flow

- Cause comfort problems

- Freeze the air conditioner coil

- Damage the compressor

- Crack the heat exchanger

- Put carbon monoxide in your home

- Dehumidify better

These are things that can happen, but what really does happen? And how do you avoid those pitfalls if you do use a high-MERV filter? We’ll answer those questions in the next two articles with a look at the research and at what works.

Next article:

Do High-MERV Filters Always Reduce Air Flow?

Buy the Awair Element on Amazon*

The Awair Element indoor air quality monitor is one of the best tools for keeping an eye on how good—or bad—your IAQ really is and whether or not your filters are keeping the PM2.5 levels low enough. I have two of these monitors in my house.

Related Articles

7 Reasons Your Filter Isn’t Improving Your Indoor Air Quality

Which Indoor Air Pollutants Matter Most?

What Happens to Air Flow in Ducts When Size Changes?

* This is an Amazon Associate link. You pay the same price you would pay normally, but Energy Vanguard makes a small commission if you buy after using the link.

This Post Has 139 Comments

Comments are closed.

Not all filters have a Merv

Not all filters have a Merv Rating & many of those are purchased at the big box stores.

Yep. Unfortunately some

Yep. Unfortunately some companies, like the big box home improvement stores, have decided to create their own rating scales, thus confusing everyone.

I have a question a out merv

I have a question a out merv 13 filters. People are using g them in between fabric on face masks. I saw some are made with fiberglass in them. Is this safe?

It seems that no one has

It seems that no one has responded to your question, Pat 1.

It just make sense never to have a person breathing through a fiberglass filter. Where will any fiberglass particles go? Into your nose and mouth.

What I wish someone would answer is whether there are other particulates in a level 13 filter that could harm those of us who are making our own masks because we can’t find ones in the stores.

Pat 2

I wish someone would answer

I wish someone would answer that question too as I saw some were using it for a breathing filter too. I took apart a Hepa filter this weekend and noticed what I thought was fiberglass fibers in it. So I am wondering if a vacuum filter contains any and if it is better.

I just saw a FB video from a

I just saw a FB video from a British doctor saying that vacuum bags are NOT safe for masks as they do contain fiberglass which is very bad to breath (and worse when the bags have been cut to make inserts) IF however the MERV air filters are, as I’m reading, made of polyester and cotton, they should be safe.. but probably should not be washed. What I have heard is that if you put them into a hand-made face mask.. don’t sew it in, but make a pocket to insert it. As COVID-19 can only last 3 days maximum on this type of surface.. have at least 4 inserts available and rotate them daily, so each gets a 3 day rest.. will then be virus free (if not touched).. the mask can and should be washed without the insert in it.. as the insert will be less effective after washing. Hope that’s helpful.. all based on internet research.. I”m not an expert by any means, but this makes sense to me!

All research I have done on

All research I have done on vacuum cleaner bags say they do not contain fiberglass. It is the HEPA filters that go into an air purifier unit that contain fiberglass. Vacuumed cleaner bags that are labeled HEPA are not the same thing. And every available brand says they do not contain it. This MERV filter is questionable as if it will really be effective for this use as from

what I understand they need a electrostatic charge that they are not getting when put in a mask. And I don’t know about those filters being that close to the face even if covered in fabric. I will stick with my N-95 masks for now. It seems that there has been enough time for researchers to do the tests on all these filter options but I don’t see anything from the CDC or any reputable organization about any of it. Everything seems to be opinionated and not factual. The other thing is isn’t the virus 0.1 microns? So this MERV filter is said to stop 0.3 microns particles? So the virus will pass through it it seems? I just want everyone safe and to have complete info so they can make an educated decision. I would hate to see that later on people are having respiratory problems from these home made masks with filters what they thought were safe. I can 99.9% guarantee that it’s going to come out later with people that have developed respiratory issues from all of this. Be safe!

I also landed here trying to

I also landed here trying to figure out what material the Honeywell Elite Allergen Air filter media is made of. After I bought it this morning at home depot to make masks. The rating is FPR 10 which is supposed to be a MERV14. Hopefully its not made of fiberglass or glass fibers. I’m seriously surprised by how little information is out there about what these filters are made if given that they are used to improve indoor air quality.

I too am here for the exact

I too am here for the exact same reason… Seems like the consensus is that it is made of polyester/cotton. Any additional info you may come across pls share here it is greatly appreciated.

Just an update I called the 1

Just an update I called the 1-800 number on the package and was able to speak to the representative and she confirmed that the Honeywell FPR 10 Elite Allergen Filter does not contain any fiberglass or spun glass. But she also mentioned that the material is not recommended for face mask use. But is used as a filter media in hospital and pharmacy settings.

More often than not Hepa

More often than not Hepa filter vacuum bags contain glass microfiber’s and definitely should not be used in face masks. You can always call the manufacturer for more definitive info. 🙂

when i was reading the very

when i was reading the very small print, in the FAR RIGHT column it DOES say that there are micro-fine fiberglass particles in the Merv 11 – 16. i think it was about the second or third line down in the that column (FAR RIGHT). i would think micro-fine would be more dangerous (?) as it would have the ability to filter through almost any material i can think of. i am certainly NOT an expert on ANY of these things; i am NOT making a recommendation on what filter to use or not use. i am basing MY PERSONL opinion on what i’ve read, and good ol’ fashion common sense. either print out the chart or be quick about making your decision, because i did notice it was a “not secure” website.

http://www.mechreps.com/PDF/Merv_Rating_Chart.pdf

AGAIN, THIS IS NOT MEANT AS A PERSONAL RECOMMENDATION OF ANY KIND; THIS IS SIMPLY INFORMATION I HAVE FOUND WHILE DOING RESEARCH ON THE DIFFERENT FILTERS TO BE USED IN A COVID-19 MASK.

The fiberglass is only in the

The fiberglass is only in the bag filters, not in box filters (as were discussed in this article). Box filters are used in household/business HVAC systems.The brands mentioned use no fiberglass. Bag filters (aka baghouse filters) are used in filtering liquids, so less available for us.

By the way, surgeries have a variety of merv filters, and HVAC systems use merv filters – in both cases, they do not use fiberglass.

Hepa filters are more

Hepa filters are more commonly made of melt blown polypropylene and perhaps another poly but not fiberglass, but do homework and examine package carefully

Yes, I’m looking for the same

Yes, I’m looking for the same answer about using a merv13 pleated air conditioning filter for part of a mask. Is it safe?

I was looking for the same

I was looking for the same info, as we are looking to find 2 ply non woven polypropolyne materials for this (reusable shopping bags so far). The 3M site states not to do it with their furnace filters, but I could not find out what they are made of anywhere.

Dr Reena Killian, a part of a

Dr Reena Killian, a part of a team of Toronto doctors (currently testing some designs) said to use ONE layer of polypropylene sewn like the surgical mask, no need for extra filters – 3 pleats, is good enough for catching droplets – for shopping, medical work not with covid 19 patients etc. Its the material reusable grocery bags are made of. Its washable and I hear you can boil them for 10 min to sterilize. Its what surgical masks are made of. I’ve seen designs using 8″x9″ rectangle. make sure no holes in the main part – by pins, tiny tears etc. I used the edging of the bags for straps. or pieced together strips for straps to tie at the back of the head. (remember, No logos or waterproof parts in the main part – not breathable! I found I needed to put 4 pleats so it wasn’t too wide at the ears. I am working on a pattern to post. wire in the nose peice- using real wire now, but twist ties or pipe cleaners will work.

There is this: https://www

There is this: https://www.airfiltersdelivered.com/20×36-merv13media-p=P25media they say its safe for inside masks.

Nothing on that site link

Nothing on that site link says they are safe for masks

Greetings, researching DIY

Greetings, researching DIY Facemasks also. It seems that using the high merv filter media, blasting it with compressed air, and then inserting the filter into a pocket of the DIY facemask, between the two layers of fabric, would suffice. I wouldn’t want to wear it for days, but a grocery store trip is certainly reasonable. Additionally, when needing to sanitize face masks, put mask into the microwave with a damp paper towel and heat it until the towel steams, that is going to be high enough heat to disable the virus. A hair dryer also gets a mask hot enough within 20 seconds (by my testing and laser thermometer) to zap the virus. Corona is very contagious but EASILY disabled by heat or detergency (like washing your hands),

.

You can also sanitize your

You can also sanitize your homemade mask with an ozone cleaner. I have one I purchased to clean my cpap equipment. Ozone cleaners themselves have risks of their own if not used properly. Do it in a well ventilated are, also allow your mask to air out for a few hours after cleaning.

I have read that you must not

I have read that you must not microwave a mask. They are electro magnetically chargeg and microwaving or laundering them will render them ineffective.

They have metal and will

They have metal and will catch fire. Wash them w/o the filter if u put one in

Most of the masks have a

Most of the masks have a metal nose piece and should not be microwaved. They can and have caught fire, in addition to contaminating your microwave.

From the CDC website for

From the CDC website for decontaminating face masks:

“Microwave generated steam 1100–1250 W microwave models (range: 40 sec to 2 min)

All models passed filtration evaluation for 1 or 20 treatment cycles as per test 95–100% passing rate after 3 and 20 cycles for all models tested”

“Microwave steam bags 1100 W, 90 sec (bags filled with 60 mL tap water) Passed”

https://www.cdc.gov/coronavirus/2019-ncov/hcp/ppe-strategy/decontamination-reuse-respirators.html

Bottom line: If microwaving kills the virus that causes COVID-19, your food will be safe and your microwave will not be contaminated. We often eat food then put the contaminated food into the microwave to be reheated. We rarely think about the fact that we are destroying germs including viruses when we microwave our food hot enough and long enough.

The CDC website is clear about what is known about decontamination of face masks.

Hope this helps.

You can also use a HEPA

You can also use a HEPA vacuum cleaner bag. I’ve seen some mask filter inserts using those if you don’t want to use the MERV 13.

Wait a second… doesn’t that

Wait a second… doesn’t that also apply to having those filters installed in every AC in every home? Aren’t we all already breathing all those fiberglass and other particles/substances? I understand they come more diluted, but still…

If I am not mistaken, Merv-13

If I am not mistaken, Merv-13 and higher do not usually contain the fiberglass components.

Pat, it’s probably fine but

Pat, it’s probably fine but anytime you have the possibility of breathing something into your lungs it’s best to be cautious. The early research on rats and fiberglass that led to fiberglass being considered a carcinogen has not been substantiated and fiberglass used as a building material is not on the list of possible carcinogens anymore. (See links below.)

But MERV 13 filters aren’t made with fiberglass as far as I know. They’re made of polyester and cotton. I think they’re also bound pretty well together but if you can see any kind of dust coming off the filter when it’s new, that wouldn’t be good to put over your face. But if anything comes off the filter, it wouldn’t be acting as a good filter either.

https://home.howstuffworks.com/home-improvement/household-safety/dangerous-insulation1.htm

https://insulation.org/io/articles/cancer-warning-labels-removed-from-fiberglass-building-insulation-products/

This is the only place on the

This is the only place on the internet that I could find a solid answer that these filters do not have fiberglass, and are made of polyester and cotton instead of just paper, so thank you. Also, thank you for confirming that fiberglass is not carcinogenic.

I’ve been working on designs for masks for hospitals but have read that simple cotton masks are insufficient, that there needs to be a filtration mechanic. Obviously all the big time stuff is occupied or yet to be made. But MERV 13 filtration looks like a great solution. If it is polyester and cotton, it ought to be able to be sewn into a mask and washed just like any other fabric. I doubt that these household air filters are designed to be washed, as they are framed in paper for starters and designed to be disposable. But a solid cycle through a washing machine while cradled between pleated cotton that will be just the ticket. I am super stoked. Additionally, even though these are pricey filters, due to their excessive pleating you get double the material than the external dimensions than the actual filter!

I’m glad I met you, Allison Bailes! You are not only super smart, but also super rad! I will be looking out for more of your articles. 🙂

Hello, I’ve been working on

Hello, I’ve been working on mask designs day and night. I had a stiff poly tightly woven fusible and nonfusible innerfacing that I have been making mask molds out of. Then I take two layers of MERV13 material and sew it to the mold.

Then I use a patterns like the N95 mask, put darts on the top and bottom for nose and chin comfort and face fitting, then I take two seperate materials, a quilted stretch poly/cotton and a thick stretch cotton and make outer layer that holds the mold. It’s not easy to do, my sewing machine is the older version Kenmore Ultrastick that is all steel and can handle these multiple layers, the mold and outer material has to be sew down the center, not easy to do with thick layers, each one I have made has taken a couple hours (getting that time down) to make, but I have been successful with a mask I do not see anywhere else.

Can you send pix of your mask

Can you send pix of your mask and the pattern?

Janet, I love your idea! Have

Janet, I love your idea! Have you received feedback from HCP who have worn them for several hours per day? It’d be great to learn how they’re doing with them. I’m curious about the resistance factor with the multiple additional layers – the higher the filter rating the harder to breathe through I’ve heard they say. Plus with that many layers and double filter, I’m wondering if it would be too warm as well. It might still be effective less layers. All of us who found this page are clearly interested in finding/creating the highest filtration masks for the front line works vs the more general surgical pleated masks which are more helpful as N95 covers and for non-healthcare personnel. From everything I’ve read, for the N95+, it’s not only the filter material, but the fact it creates a faceseal. Adding a bendable, form fitting nose piece helps. The Olsen mask version prototype developed by UnityHealth

attempts to create that seal. Your mask construction/design is clearly a higher quality DIY – if you haven’t seen it, check out the Olsen UnityHealth version & see how they are attempting to get that faceseal. There is one other healthsystem mask that is attempting a faceseal as well but I can’t find the link buried in all I’ve collected, lol There is this interesting one that he believes provides a seal made entirely from a vaccum HEPA filter bag. Thank you for all you’re doing!!! I would love to connect with all of you working with high quality filters & construction so we can share/transfer ideas, feedback from HCP, modifications, requests, etc. @ facebook.com/kodie.river.7

I, too, thinking of how to

I, too, thinking of how to construct a decent mask. I’m thinking of trying an air filter along with a non woven material similar to what is used in the N95 masks.

I just published a new

I just published a new article on the topic of using high-MERV HVAC filters in homemade coronavirus masks. Here it is:

Can You Use HVAC Filters in Coronavirus Masks?

And here’s the URL:

https://energyvanguard.com/blog/can-you-use-hvac-filters-coronavirus-masks

Please listen to the

Please listen to the scientists, including the CDC and Dr. Faucci. The Only reason for you to be wearing a mask is to prevent the spread of the virus. The mask is not being worn to prevent you from acquiring the virus. You may be asymptomatic and spreading it. This is how we stop the virus.

A MERV 13 filter will likely

A MERV 13 filter will likely be of help if the goal is to prevent droplets from passing through. However, you’ll probably want a higher-MERV-rated filter if you are trying to stop unattached COVID-19 particles. The Covid-19 diameter is around 0.1 micron. A MERV 11 filter only needs to stop 20% of particles in the 0.3 to 1.0 micron (three to ten times bigger than a COVID-19 particle), a MERV 12 only needs to stop 35% of particles under 0.3 micron, and a MERV 13 only needs to stop half. For MERV 14, 15 and 16 are rated to stop 75%, 85% and 95%, respectively. None of them are rated for performance in the sub-micron size range where the Covid-19 is, so we don’t know whether their performance is better or worse.

I noticed the comment on

I noticed the comment on filters, particle sizes, and the size of the SARS-CoV-2 virus. Filters, including the N95, pass particles the size of the virus, however, because the virus exists in a droplet, it is larger, and the var der Waals force attracts it to the filter media. It gets attached and the droplet evaporates, leaving a dead virus. Job done. 3M has published credible peer-reviewed third party studies confirming this.

Thought you would like to know. Cheers.

This comment should have

This comment should have ended the thread…

Janet I am currently printing

Janet I am currently printing up a mask that will be plastic injectable, I will be using MERV13 =and im looking for a sewer or great idea.

I can have 220 million in 8 weeks with an executive order

I was looking for the same

I was looking for the same information because I’m making masks for my nurse family too. I may try washing some of the material first, or simply cut it into small rectangles to use as disposable filters but I think they could be hand washed and sanitized with a hot dry iron for reuse.

You can NOT wash these

You can NOT wash these filters and expect them to remain effective. From what I understand, the filters, like N95 masks, have been electronically charged. Laundering them would render them useless. The filters and masks can be sanitized, from what I read somewhere, in a low temperature oven – followingvery specific guidelines. If I can find the article I will return and post it here.

The word you keep reaching

The word you keep reaching for is “electrostatic”. Still not a good idea to put them in a microwave nor washing machine. Evidence that an alcohol soak or UV-C exposure does the trick, though. Do your research, don’t get your information from conversations like this.

Many of these non-woven mesh

Many of these non-woven mesh product loose their structure when washed with soap and water or submerged into alcohol. Without being able to test it, I would not assume you can wash it. 30 minutes in a 160F oven should be safe (it works for real N95 masks) or make extra and rotate it in and out of use on a 4-5 day cycle.

It appears it’s made of

It appears it’s made of cotton and polyester and if put in a mask with a pocket you should be ok. I just took one apart and it feels and looks as stated. Would be nice for an answer from company.

I called the manufacturer of

I called the manufacturer of the MERV 12s I have (and am using), and the company confirmed that ther was no fiberglass in my filters. I think it is best to insert the filter into a pocket in the mask, but I’ve found those types of masks to be a pain to make (the sides become very thick, and inserting the filter into the pleated mask doesn’t totally reach edge-to-edge). I’ve since been making masks with the filter sewn in between two layers of fabric. I guess I should wash one now to test how well it will stand up to laundering (with the filter sewn in instead of slipped in).

Did you wash a mask with the

Did you wash a mask with the filter? Let us know your results.

Hi Jana,

Hi Jana,

I’ve washed the filter material and it responded beautifully – it became softer and still easy to breathe through. I’ve yet to wash the completed masks, but will certainly do so, and will try to remember to post the results.

–Marianne

Hi Allison,

Hi Allison,

You seem to know a bit about the filters, would you happen to know how much more protection it could afford if I were to add a second layer, to the mask, how about 4 layers?

Thanks!

No high merv filters are made

No high merv filters are made of fiberglass. When you have a filter of Merv 13 and above it’s more similar to the material you would find in an n95 dust mask.

Just ordered MERV-13 furnace

Just ordered MERV-13 furnace filters from an online vendor. The agent with whom I chatted said that none of their furnace filters contain any fiberglass.

Hi,

where did you order?

Hi,

where did you order?

No need to buy filters. You

No need to buy filters. You can purchase the MERV 13 material only at Filti.com (they offer MSDS with great detail). Also, Try a free sample of their material from Airfiltersdelivered.com

I’m using a layer of Merv

I’m using a layer of Merv 1900 3M Filtrete in my mask (I made the mask like a slipcover so I can remove the filter for washing). Since it was so difficult to find information about what the Filtrete material is actually made of, I thought I’d share what I discovered:

3M Filtrete is made of: “3M Filtrete filters contain electrostatically charged filter media made of polypropylene and polyolefin plastic, and capture particles that measure between 0.3 – 10 microns in size. The electrostatic properties cause the filter to act like a magnet, helping it to attract both large and small particles into the filter’s pleated fabric.” (Source: https://www.iallergy.com/pages/compare-3m-filtrete-filters)

Is it toxic? Toxicity of polypropylene and polyolefin plastics: “In homes and automobiles, clothing and carpeting, health care and industry, polyolefin is quietly at work in thousands of applications around the world. Polyolefin plastics and fibers keep our carpeting clean and transport moisture away from the body to keep our active wear dry. They protect sterile environments and soak up industrial spills.” (Source: https://clearandwell.com/what-is-polyolefin-plastic-and-is-it-toxic/)

Another site discussing the low toxicity of PP and PE: “…whereas polypropylene (PP), … and polyethylenes (PE) were evaluated to be the least hazardous [polymer types].” (Source: https://www.blastic.eu/knowledge-bank/impacts/toxicity-plastics/)

HOWEVER, none of these discussions consider cutting the fibers and breathing them, so who knows. The plastics will not withstand heat and they degrade with UV rays, so I wouldn’t suggest heating them to sterilize. Rather, I plan to slip the insulation out of the mask, wash and dry the mask, and then add fresh insulation. The insulation can be reused a few days later (we know the virus doesn’t live on soft surfaces for more than a few days).

That’s a good answer and

That’s a good answer and exactly what I was thinking, to change them between uses rather than sterilize or wash them, that may cause to the materials not work properly, thank you!

Covid 19 is .125 microns

Covid 19 is .125 microns

Dlite, just a little

Dlite, just a little clarification on the terminology and dimensions of the novel coronavirus. COVID-19 is the illness one gets from the virus called SARS-CoV-2. The size of the virus itself varies from 50 to 200 nanometers, or 0.05 to 0.2 microns. So the number you gave is in the middle of that range. But the virus is rarely found by itself. It’s usually a part of droplets of various sizes. Aerosols are the small ones, generally from 1 to 10 microns, and can keep the virus intact and infectious floating around in the air for up to three hours. The larger droplets that we expel by breathing, coughing, or sneezing, are mostly 10 to 100 microns. They can harbor a lot of virus but spend little time in the air.

The Wikipedia page on SARS-CoV-2 has a lot of information on the emerging science of this virus.

https://en.wikipedia.org/wiki/Severe_acute_respiratory_syndrome_coronavirus_2

My background is in aerosol

My background is in aerosol (fine suspended particles like air pollution) science and hence also filtration. It turns out that one sees these kinds of size ratings because “intermediate” size particles around 0.5 microns are the HARDEST to filter out. Smaller particles, less than roughly 0.2 microns get easier to collect the smaller they are. That is because they are bounced around rapidly by air molecules compared to the flow velocity and run into the mask’s fibers and stick. (Small particles are very “sticky” due to Van der Walls forces.) This “bouncing around” is known as Brownian Motion. Larger particles > than about 2 microns, tend to travel in a straight line and impact the mask’s fibers (and stick). [More technical note: Smaller fibers will collect smaller particles by impaction, but also they have less surface area to catch them (and the smaller) particles. These effects result in a trade off between collection efficiency and higher pressure drop and filter thickness.] Caveat: This is off-the-top-of-my-head–for more precise info, one should consult a good text book or handbook that covers fine particle filtration.

Study on cleaning masks.

Study on cleaning masks. Considering electrostatic change performance and washing.

https://news.stanford.edu/2020/04/01/researchers-show-how-to-decontaminate-reuse-n95-masks/

Hi Sonja,

Hi Sonja,

I think you’re going about it the right way, I don’t have a cotton/clothing mask but I do is have surgical masks which over the vital area of the face very well and what I’m done, I’m using two of them, with a layer of MERV 13, MPR 1500-1900, FPR 10, hmmm, I wonder what happens if you double the layers on these filters, will they double the protection? Has that been answered?

Thanks so much and be safe!

Thanks so much for sharing

Thanks so much for sharing your research!!

Very helpful! Thank you for

Very helpful! Thank you for doing the research Sonja and providing links. I’m making covid masks with a pocket and taking apart 3M Filtrete 1900 and inserting them into my fabric masks.

I heard there was a study

I heard there was a study done in Korea that concluded that face masks required 7 days before all the corona virus was dead on it , I’m assuming that this was longer than is normally quoted for fabrics because the very critical nature of not having a face mask with any active virus in it , so they really checked it well.

I also use pieces cut from 3M

I also use pieces cut from 3M Filtrete. Masks should be changed often, at least daily, so I have several and launder mask, then soak the filter in alcohol, then lay filter flat on clean surface to dry. Alcohol disinfects very well if strong enough, and if allowed to dry by itself on the surface, or in this case, soaked into the filter fabric. The alcohol must be isopropyl 60% or higher, or grain alcohol (ethanol, that is, for drinking) greater than 120 proof. An example would be “Everclear,” but not your regular alcoholic beverage which is not strong enough. (Also acceptable for home-made hand sanitizer.)

Buy washing an alcohol you

Buy washing an alcohol you very well might be creating some funky weird strange chemicals unless you’re just washing cotton so I would just use sunlight to disinfect them even that might break down high Merv filters somewhat and release unintended perhaps dangerous chemical outgassing a activated charcoal filter high Merv might be your best bet between you and whatever other exotic type chemical action you got going on

There remains too much focus

There remains too much focus on N95 disposable masks. The elastomeric facepiece with P100 cartridges or PAPR should be being used by any front line worker who does not need to communicate clearly to strangers. My personal mask for casual interactions- grocery store… Is two layers of cotton with one of cotton flannel inside. When working the PAPR is my friend! We can do better when we use what we know. Where are the Industrial Hygienist in this conversation?

There remains too much focus

There remains too much focus on N95 disposable masks. The elastomeric facepiece with P100 cartridges or PAPR should be being used by any front line worker who does not need to communicate clearly to strangers. My personal mask for casual interactions- grocery store… Is two layers of cotton with one of cotton flannel inside. When working the PAPR is my friend! We can do better when we use what we know. Where are the Industrial Hygienist in this conversation?

I’m also interested since I

I’m also interested since I bought the fabric.

Pat, fiberglass would not be

Pat, fiberglass would not be my first choice but using a filter, in general, is a good idea. I’m using a HEPA filter in my mask (bought a vacuum cleaner filter) and aside from the slightly weird plasticky smell, I believe it keeps me safer while buying my bread.

I am simply trying to find

I am simply trying to find out if the material my relative used in the mask has fiberglass in it?

Same question re is MERV 13

Same question re is MERV 13 filter effective and safe to use between fabric for face masks? Thanks for input.

Yes they are safe and

Yes they are safe and rewashable. The best you can get for a custom made face mask for protection from cover. I ordered mine from eBay for like 12 dollars, and did I mention they last a year and are washable.

I went on Amazon and found

I went on Amazon and found Merv13 filter cloth. 16sq ft for under $20. No fiberglass. I cut small ovals and put a piece of double sided tape on the edge and stick it on the inside of my premade cloth mask. Works great.

Can a MERV 13 be incorporated

Can a MERV 13 be incorporated into a DIY face mask to help protect from the coronavirus? I saw a YouTube demo where there person cut off the metal in the 1″ filter, cut a piece of the material and smoothed it flat to insert into the mask. Would being flattened like that reduce the effectiveness? Would I be able to breathe though it (along with a cotton mask material)?

Thank you!

I found this article the most

I found this article the most helpful of any I’ve seen. Basically, for non-medical lay person masks, it’s best to use fabric. See article for details about why. Convinced me (after I’d made some with non-fiberglass vacuum bags, etc) and now I’m making 3-layer masks – outer layers woven cotton, inner layer flannel. Again, see article for why this is a better idea than microfiltration. https://www.washingtonpost.com/health/2020/04/07/answers-your-diy-face-mask-questions-including-what-material-you-should-use/?arc404=true

Can I use a merv 10 or Merv

Can I use a merv 10 or Merv 13 filter material in a DIY face mask?

Pleats provide more filter

Pleats provide more filter media surface area within the filter’s housing. More surface area means more air flow. Flattening the filter media does not change what it stops and lets through.

That idea would fall under

That idea would fall under the ‘better than nothing’ category of

protection. You asked if it would help to protect against Coronavirus exposure.

It will help, yes. But you will still need goggles for eye protection and still practice social distancing. Also, were I myself to try this MERV13 filter modification, I would make many filter disks and change them after every exposure to several people. They cannot be recycled, so be prepared to make hundreds of them. Whatevr contraption you make, be sure that the edges of the filter are making a good seal around you face. No beards! Best of luck.

The Merv 16 would be the best

The Merv 16 would be the best as it will filter out 95% There is a youtube video showing how to make your own N95 out of a Merv 16 filter

i disagree Since a buildup of

i disagree Since a buildup of particulates can block airflow and reduce the efficiency of your air conditioner and furnace, most people assume that finer, thicker filters will have the same effect on your furnace, since the air will pass through more filtration points as it moves into your air handler.

While this assumption may have carried some clout a decade or so ago when these high-efficiency filters were new, modern varieties can actually increase airflow, save you money, and keep your system cleaner.

Air filters are rated based on the MERV scale, which stands for Minimum Efficiency Reporting Value. The higher the MERV, the more particulates filters collect. While air filters with a MERV of one to four are effective at removing large particulates like carpet fibers, airborne paint droplets, and sanding dust, they can’t help with contaminants like hair spray, mold spores, or even flour that might have escaped your mixer.

However, high-MERV filters offer superior filtration, trapping everything from construction dust and tobacco smoke to bacteria.

By installing an air filter with a high MERV rating, two things happen. First and foremost, your air becomes cleaner, which can help improve the longevity of your HVAC system. The more particulates that are trapped, the fewer get stuck to the interior of your vent work, and the better the airflow becomes.

Additionally, high-MERV air filters that contain pleats create a lot more surface area for air to blow over, which can improve airflow and reduce the strain on your system. In fact, researchers have found that while high-MERV filters can create some pressure drop, the impact isn’t

significant unless your filter is laden with dirt.

Brad, you ought to read some

Brad Young, you ought to read some of my other articles, this one in particular:

Do High-MERV Filters Always Reduce Air Flow?

increasing a filter to a

increasing a filter to a higher MERV may increase the delta P across the filter. Suppose you put the higher MERV in series downstream of a lower MERV rating, will that help the delta P across the filtration in total?

Wouldn’t a greater pressure

Wouldn’t a greater pressure drop across the filter decrease the pressure in the duct system not increase it?

Andy, yes, you’re right. A

Andy, yes, you’re right. A big drop across the filter means the pressure in the return duct is lower, not higher. But the pressure difference between the return duct and the air outside it will be higher as a result. Also, the total external static pressure in the system will increase.

I just realized we have two

I just realized we have two different pictures in our head. I’m thinking of a typical Michigan basement furnace with the filter 4 inches from the blower motor and all of the outside of that.

Not all of us know what a

Not all of us know what a Michigan Basement is. As I recall it is not a basement in Michigan.

I actually did just mean a

I actually did just mean a basement in Michigan in this case, to differentiate from an attic in Georgia. But for the record what we call a Michigan Basement, which is probably not unique to here, is when a crawlspace is dug out into a basement and the soil under the existing footing is shored up (sometimes in frighteningly inadequate ways). They are easily recognized by the step in the wall and low ceiling height (I think people got tired of digging).

If you’re using VRF mini

If you’re using VRF mini-splits in a tight house, what kind of system would you install for filtration?

Good question, Lee. If those

Good question, Lee. If those mini-splits are ducted, it’s easy to put in a standard filter. That’s what we’re doing in our office. With ductless mini-splits, you’ll have to get your high-MERV filtration elsewhere. It could be in a standalone filtration system with its own fan. It could be part of the ventilation system.

One option, particularly for

One option, particularly for the South, is a Ventilating Dehumidifier (e.g., UltraAir 98H). Comes with a MERV 13 filter. They have external housing for a MERV 14 filter as well, kind of wish I’d gotten that installed as well.

http://mattrisinger.com/dehumidifier-necessity-for-texas-homes/

Probably useful even up north, but perhaps there are ERVs with enough ummph to handle MERV filtration as well?

James, yes, a ventilating

James, yes, a ventilating dehumidifier is a good choice for mixed-humid and hot-humid climates and it can definitely help with the filtration. Depending on the size of the house and the static pressure, though, you may or may not get enough filtration volume. Most energy recovery ventilators (ERVs) and heat recovery ventilators (HRVs) don’t give you MERV-13 or better but there’s at least one that does: the Zehnder CA200.

The Broan (used to be Venmar

The Broan (used to be Venmar units) ERV200TE has a HEPA option. Also has my favorite controls in the Broan line because you can independently select the high and low speeds, each from the full range, and balances by reducing motor speed instead of dampers.

Hi Allison. I just want to

Hi Allison. I just want to point out that MERV-13 filters are available In ALL Zehnder ERVs and HRVs.

My impression is that

My impression is that ductless heads, being ductless, don’t have the capacity to mount much pressure head, and therefore you would look elsewhere for high-efficiency filtration, whether plug-in HEPA cleaners or a ducted dedicated ventilator designed for use with a HEPA or MERV-13 filter. Having filtration powers independent from heating and cooling demand is a good thing anyway.

Avery, you are correct.

Avery, you are correct. Ductless mini-split heat pumps come with a little filter whose job is to keep the coil clean. You have to clean it regularly to keep the air flow up.

Thanks Allison! This is a

Thanks Allison! This is a really big deal. We may be able to help our clients get a super-insulated and amazingly strong building envelope up quickly and sealed tightly with low-skilled labor, but THEN that’s where the next challenge starts – proper mechanical ventilation. And without skilled professionals knowledgeable of proper filtration and its appropriate motor sizing you can be creating problems instead of solving them.

All too true, Charles. As my

All too true, Charles. As my friend Kristof Irwin says, we need to fight the “hegemony of enclosurism.” Mechanical systems matter!

Brent Stephens’ Built

Brent Stephens’ Built Environment Research Group at Illinois Institute of Technology did some measurements of filters that can be found here: http://built-envi.com/portfolio/filter-testing/ In terms of pressure drop, the data appears to show that the main way to get good filtration while minimizing pressure drop is to use larger filter depths. For example, the 5″ deep Lennox Healthy Climate MERV 16 has about 40% less pressure drop @0.12″ wc compared to the 1″ 3M MPR 600 (equivalent to MERV 8) @0.21″ wc.

Brian, you seem to know where

Brian, you seem to know where I’m going. Brent’s paper from his grad student days at UT Austin with Jeff Siegel is one of the studies I’m going to discuss in the next article. And I’ll be talking about the issue of filter depth.

This is why a deep filter

This is why a deep filter media cabinet and a semi-annual preventive maintenance program comes with every heat pump system we install.

Be a little careful specifying high MERV filters with ducted mini splits – their air handler “static budgets” are often much lower (1/4 – 1/2) than that of conventional air handlers…depending on individual system circumstances, there nay not be enough static to spare. Proceed with caution.

Curt, yes, you have to know

Curt, yes, you have to know what you’re doing to do high-MERV filters on ducted mini-splits. But I’d argue that you should be just as careful with doing it on any ducted system. John Semmelhack gave a talk at the North American Passive House Conference in Boston this year and showed how they’re putting MERV-13 filters on Fujitsu ducted mini-splits and doing so with a pressure drop of only 0.03 i.w.c. We’re in the process of installing a Mitsubishi ducted mini-split rated for only 0.2 i.w.c. in our office and are aiming for 0.03 i.w.c. or lower. I’ll let you know how low we get it after it’s installed.

Hi Allison,

Hi Allison,

Great topic and discussion. Home Energy published an article by Dave Springer of Davis Energy Group at the time, of pressure drop and energy use of several MERV filters. It was from 2009 but still quite relevant I think. Here is a link to the free article:

http://homeenergy.org/show/article/nav/indoorairquality/id/667

Jim, now you’ve gone and

Jim, now you’ve gone and spilled the beans on one of the other research studies that’s going to be part of my next article. And yes, it is absolutely still relevant.

An HVAC instructor I know

An HVAC instructor I know used to say the most efficient air filter is a piece of plywood. No particles would get through it, but no air would get through it either.

I was fairly comfortable

I was fairly comfortable looking at filtration for PM2.5 (even thought it becomes obvious that the best way to address that is with a stand-alone air filtration unit) until I saw the HomeChem scientists’ video series on YouTube. PM0.5 particles? Ozone causing new chemical combinations? Now I’m much more alarmed and see that all this discussion about IAQ looks to be too little, too late.

Great article. Improper

Great article. Improper filter design extremely common, and is one of those “little things” that can kill system performance, in more ways than one.

Increasing filter surface area (by increasing depth and/or length & width dimensions) solves the pressure drop issue. In new construction this is easy to achieve. My specs require filter face velocity not to exceed 200 FPM, or roughly 2 sq.ft. per ton. Even less for ducted mini’s. Problem solved.

Existing construction is more challenging. Simply replacing a 1 inch filter with a 4 inch may not be enough, especially if the filter cabinet is mounted at immediately before the blower (sized to match the return opening). In that case, it’s sometimes easier to get rid of the filter at the air handler, add another return and install filters at the return grilles. But ‘ya gotta make sure those return ducts are tight. Otherwise bypass will eat your lunch.

New homes utilizing ductless

New homes utilizing ductless mini-splits shouldn’t have a significant need for additional fine particle filtration, unless they are affected by outside sources such as high ambient pollution levels. For many homes, a HEPA filtered vacuum provides enough control of particle pollution to maintain good IAQ.

David Eakin, I wouldn’t stress too much about the research on ultrafine particles and ozone reactions. That research is for ambient (outdoor) air or specialized research or manufacturing environments. Unless you have a local ozone source, there is seldom enough ozone indoors to cause those issues. A metallic coil is an excellent ozone filter, so nearly all residential HVAC systems are effective ozone filters. And residential HVAC system design is the wrong place to address ultrafine particles or filtering to clean room standards. Let’s focus on the benefits to the most people, not the special cases that might need additional particle controls.

Right, but I happen to live

Right, but I happen to live in an area where frequent ozone “action days” occur – SouthCentral PA. Many hundred thousand of us, mostly in old or “code” houses so I’d suspect lots of indoor ozone due to leakage. The truth is “most people” do not live in Passive House air tightness, nor in new “code” houses (look at new home building stats) so the largest benefit will be to people living in older homes. And in much of the mid-Atlantic – without forced-air HVAC units (maybe add-on AC units with air handlers and ducts run in all the wrong places). So if you really want to “focus on the benefits to the most people” you will not be focusing on the 1% (or less) that can/choose to afford a new construction, highly-engineered house.

I am a builder/designer, not

I am a builder/designer, not an HVAC guy. But D. Butler’s comment above echos a design solution I have already incorporated. Build the return so that it can house 2 18×18 high Merv filters side-by-side giving you 648 SI of surface area for filtration.

Love this comment. We like

Love this comment. We like ample plenums ‘round here! And that applies to flirtation. There is a reason that 8” return duct has a 20×20 filter!

It is really sad that most

It is really sad that most manufacturers do not report air pressure drop (clean or dirty). The general thinking is that the higher the filter efficiency, the higher the pressure drop, but that is not always true. In the past, we tested some popular retail home air filters from a single manufacturer (all 24″x24″x1″) and found that their highest efficiency filter had lower pressure drop than their next highest efficiency filter. That puzzled us at first until we noticed that the highest efficiency filter had many more pleats, thus more surface area. Unfortunately, without any published information on this, the buyer cannot make an informed decision.

With all due respect Allison,

With all due respect Allison,

I question the need for MERV 13 filtration. No one is filtering exterior air for us. Have you observed what’s being put into it? If one’s interior air is so polluted that it requires MERV 13 then one is only treating a symptom of a larger problem.

2ndly I question the idea that a furnace air handling system should be used to ‘purify’ interior air.

The purpose of a furnace filter is to protect its equipment. Using a filter designed to just do that does not put system function at risk if the filter is regularly maintained.

This is, of course, KISS principal and does not accommodate those selling more costly filters needing more frequent replacement or anyone else propagating & preying on people’s uninformed fear.

The way HERS rating is done

The way HERS rating is done in California has for some time militated towards outdoor air supply being provided by a separate route from heating and cooling, as an uncontrolled CFI outdoor air intake is not allowed to be sealed off during duct leakage verification. Also, most low-capacity air handlers are not capable of mounting the static pressure needed for high-MERV filters, so CFI setups with those often necessitate inline booster fans.

As to the need for high-MERV filtering, it’s easy to blow it off until you’ve met someone with allergies or asthma.

@Mark, personally, I would

@Mark, personally, I would never install a MERV 13 on my own HVAC system but with many of the OEM’s making indoor IAQ a core part of their marketing strategies, the idea that a furnace or AHU filter is solely there to protect the equipment has gone by the wayside. After all, who other than the company that designs/manufactures/sells a product is more qualified to define it’s purpose! Moreover, while I try to educate my clients on the merits (or lack thereof) of expensive, restrictive high-MERV filters, who am I to dictate what type of filter they want to use. I just want to make sure they’re doing it for the right reasons.

To Avery’s point, in new construction it’s easy to accommodate a high-MERV filter without a static pressure penalty (see my previous comment). The real problem is when the homeowner installs one of these filters on a system that wasn’t designed for that. Cudos to Allison for calling attention to this issue in this blog.

Actually, I have one thing to

Actually, I have one thing to bounce off the forum. I had actually wanted to do a separate HEPA filtered supply ventilator in my house, but for the last install our HVAC guy talked me into a CleanEffects stage on our Trane system. Here’s the thing: when I go to clean the pre-filter, I do see dust buildup on it. However, I never see much of anything in the electrified stage. I’m not sure if I should be suspicious.

David,

David,

Like Allison’s, I am always interested in and respectful of your thoughts and opinions.

There’s no more successful “Marketing Strategy” than one that convinces a client that they have risk without proof and that the best solution is at hand, so to speak. I’ve often thought that the word fear should always have a dollar sign on both ends & like Don Quixote, I’ve never seen a windmill, that I wasn’t ready to joust with.

Addressing a problem is a job, treating its symptoms is a career. There’s no question as to who brings down the big $$$s which is why there must be a 1:100 ratio of problem fixers to symptom treaters in the economy. Where that eventually takes us should be self evident.

I assume all my clients can understand elementary level physical science to I tell them that the quality of the air in their house is a function of where they live, what is inside their living space & how they live in it.

Of course it’s also a function of the air tightness of a house, but for 99% of the existing housing stock, the phrase “air tight” should not be used in any description of them.

I follow that up with explaining how there are several devices and appliances designed to clean homes including vacuum cleaners, but that HVAC systems are not one of them.

I also explain that fine filters clog faster & that clogged filters & coils quickly reduce comfort in some rooms in very hot or cold weather and can damage or reduce the life of the equipment.

Lastly, I say that there is no price for peace of mind and that if they feel that a high MERV filter would provide that they should to go for it with the caveat that they must replace the dirty filters often enough & that may be a week or two, depending on the MERV rating, effective area of the filter and how much particulate gets into their house.

Thanks again for all you guys contribute to this list.

Mark

What MERV is required simply

What MERV is required simply to keep the air coil clean enougth to ensure a high level of temperature exchange efficiency?

Individuals differ in their

Individuals differ in their need for high cleanliness air. Those who suffer from idiopathic pulminary fibrosis may reasonable hope that higher quality air filtration will help prolong their life, already shortened by the disease.

“There’s no question as to

“There’s no question as to who brings down the big $$$s which is why there must be a 1:100 ratio of problem fixers to symptom treaters in the economy. Where that eventually takes us should be self evident.”

Uhhhh, where was this handbasket supposed to take me again?

So at first you say to use a

So at first you say to use a MERV-13 filter. Then you say NOT to use a high MERV filter. I can’t find a filter above MERV-13, so that’s what I would consider high-MERV. Your article is very confusing. You should define what “high-MERV” is if you want people to avoid it.

Sorry for any confusion, Dan.

Sorry for any confusion, Dan. I couldn’t find any place in the article where I said not to use high-MERV filters but maybe the list of problems led you to that conclusion. The truth is you want a high-MERV filter, which is defined different ways but let’s say it’s MERV 8 and higher. (MERV 16 is the highest on the scale but those are hard to find.) But to use a high-MERV filter, you have to avoid the unintended consequences I mentioned above. Basically, that means having enough filter area that you don’t have a big pressure drop across the filter. I’ve got an article on that coming soon.

In case you didn’t see it yet, here’s one of the two followup articles I promised above:

Do High-MERV Filters Always Reduce Air Flow?

Mcmaster Carr makes the Merv

Mcmaster Carr makes the Merv-15 air bags which are being tested for face masks by some universities.

Please clarify the 90%

Please clarify the 90% capture of PM2.5 statement, “to achieve MERV-13, a filter has to catch…..90% of particles in the 1-3 µm range (where PM2.5 is),…”. According to other sources, one being the EPA, MERV 13 captures at least 50% of PM2.5 (the 1-3 micron range, aka level 2 of the three categories PM is referred to for air quality/filtration). While the 90% capture rate is true of larger size particles (3-10 microns), which is a very good thing, and nothing to sneeze at (sorry, couldn’t resist, lol!), it is concerning that the general message I see on product labeling and in various articles, like this one, gives readers the impression that PM 2.5 is captured at a much higher rate than the actual MERV 13 rating. For a lot of people, it’s probably not an issue, however, from an informing-the-public standpoint, accurately reflecting the data is infinitely more helpful in the long run. If by chance, the EPA source is incorrect, or if you think I have misinterpreted it, I welcome a conversation. Thanks much. https://www.epa.gov/sites/production/files/2018-07/documents/guide_to_air_cleaners_in_the_home_2nd_edition.pdf

I don’t think a filter needs

I don’t think a filter needs to fit perfectly – the chances a particle will aim for the crack and escape the filter every time in a recirc system defy the laws of Brownian Motion.

The extra pleats make the

The extra pleats make the area the air flows over larger so your HVAC will not work any harder. A simple test with an amp meter confirms this.

N95 masks are the equivalent

N95 masks are the equivalent of MERV-16 filters. I might point out here that most viruses are even smaller than .3µm (COVID-19 ~120nm), so a MERV-17 or higher, so long as your filter area is large enough to breath through comfortably, would be better.

Aside from crowded indoor

Aside from crowded indoor spaces, the risk from aerosolized viruses is very small – the real risk comes from virus-containing droplets, which are much larger. N95s are very good at stopping those.

Fortunately I have a 3D

Fortunately I have a 3D printer and have printed a face mask with a MERV 13 filter. From my research, I’ve found most viruses die at or below 140 Fahrenheit. I placed mask and filter in the oven at 175 Fahrenheit for 5 min. All plastic and rubber components held up well. My question is, does this degrade the filter in any way?

https://forms.gle

https://forms.gle/i3ibNJX53uEdGRs89 from

http://communitymake.ca/communitymake.ca – lots of people with 3d printers working on this and there are some breakout group connections in there I think – and

URL: covidtestingscaleup.slack.com There may be some others buried in my emails. If I can find them, I will post, as there are lots of individuals adding their expertise. Ryerson University – in Toronto, Ontario, Canada may have something or someone to contact too. Good Luck!

I have not opened these links yet, but may have something in there for you https://medium.com/@Cancerwarrior/covid-19-why-we-should-all-wear-masks-there-is-new-scientific-rationale-280e08ceee71

https://smartairfilters.com/en/blog/best-materials-make-diy-face-mask-virus/?fbclid=IwAR2PCqbLbGVB_-NPuRNARPt5HF3XZ0mnmqEU_IsvMc3lisHyXAUE6uV6V1U

https://www.huffingtonpost.ca/entry/how-to-make-face-mask-coronavirus_l_5e78cb2fc5b6f5b7c5483e17

This is a very easy mask to

This is a very easy mask to make and no ear problems. There’s a pocket for the filter.

https://www.youtube.com/watch?v=zm_NmpdgWWA

The easiest method for the

The easiest method for the layperson.

The N95 mask can be ROTATED, one mask every 4 days. Use 4 masks, numbered on the outside 1-4, for each day. They can be used each day in numbered sequence. Then start sequence over starting with mask number 1. All viruses on the mask will be dead in 2-3 days. There is no change in the mask’s properties.

I use this method and use paper lunch bags to store each mask and number the bags 1-4 and replace each bag after using each mask.

This method is per Peter Tsai, the inventor of the N95

First, I love your sense of

First, I love your sense of humor.

Second, ASHRAE is now encouraging switching to MERV-13 (ASHRAE Position Document on

Infectious Aerosols) as a measure of providing cleaner air in nonhealthcare facilities. I have exactly the same concerns as you do…

I want to introduce a carbon

I want to introduce a carbon filter, the only problem is the carbon filter is a Merv 8. If I add a second filter merv 13 is that a good idea?

Never cascade filters because

Never cascade filters because the accumulative restriction on the system will be too great.

A MERV 8 carbon filter will provide more than enough dust and allergen filtering and it will filter out dozens of toxic gasses that will pass right thru a MERV 13 filter.

Is MERV 13 a Final Filter or

Is MERV 13 a Final Filter or a Medium Filter for Air Handling Units? Also, is MERV 13 Filter washable? Thank you.

Homeowners shouldn’t use ANY

Homeowners shouldn’t use ANY filter without first consulting a HVAC professional about whether their system can use them safely or not.

As a 40+ year HVAC professional i have seen dozens of systems destroyed by using highly restrictive high MERV filters.

1 inch pleated filters are 2-3 times more restrictive than fiberglass filters right out of the box and can easily become too restrictive within 30 days of use.

If you want to use pleated filters and higher MERV filters the only safe way to do so is have a 5-6 inch media filter installed by a professional.

That way you will maintain safe air flow while getting the extra filtration you desire

Jim, thanks for your comment.

Jim, thanks for your comment. I always warn readers about filter pressure drop when I discuss this topic. The thickness of the filter, however, has less to do with pressure drop than you think. Yes, the pleats add more total area, but they aren’t always well separated. Here’s an article I wrote on three research studies on filters:

Do High-MERV Filters Always Reduce Air Flow?

Better than filter depth is the face area of the filter (length x width). Here’s an article I wrote on that topic:

The Path to Low Pressure Drop Across a High-MERV Filter

I’ve got three MERV-13 filters in my house and the pressure drop across all of them is less than 0.06 i.w.c. And that’s with three months of use.

I have two identical size

I have two identical size MERV12 filtrete filters from 3M setting on my bench.

One is a 1 inch thick filter and the other is a 5 inch filter.

The 1 inch filter has a factory rating of .31 iwc at 1025cfm printed on the filter by 3M

The 5 inch version only has .15 iwc at 1025cfm printed on it by 3M

Jim, what face velocity are

Jim, what face velocity are they rated for? Unfortunately, they don’t always tell you that, and that number is the key to minimizing the pressure drop. Even 0.15 i.w.c. is higher than it should be. And the other factor is real-world performance, which depends on face velocity and the space in the return box.

Also, you’re looking at manufacturer’s data for 2 filters. Real-world performance of a range of filters is part of the focus of those studies in the first I article I listed above. Did you read it?