The 3 Types of Heat From Heat Pumps

Since more people are using heat pumps these days, even in cold climates, let’s spell out the three different types of heat that conventional heat pumps provide. Why not! We’ve just recently covered the three main sources of home heating and then stepped back and looked another group of three sources of heat for high-performance homes. Now let’s zoom in a bit on heat pumps.

1. Pumped heat

This is the heat you get when the compressor runs. The compressor is what drives the refrigerant through the phase-changing, heat-exchanging thermodynamic cycle that allows your heat pump to extract heat from the cold outdoor air and transfer it to your warm indoor air. This is possible because the Second Law of Thermodynamics says heat flows from warmer to cooler objects…and the refrigeration cycle makes the outdoor coil colder than the outdoor air.

This type of heat is abundantly available when it’s chilly but not real cold. As the outdoor temperature drops, so does the amount of heat available in the outdoor air. That in turn reduces the capacity of the heat pump. As long as the outdoors isn’t at absolute zero —and it’s NEVER absolute zero anywhere — there’s still heat available. It just gets harder and harder to move it indoors.

Eventually, the amount of compressor heat available drops below the amount of heat needed inside the home. That’s when you need…

2. Supplementary heat

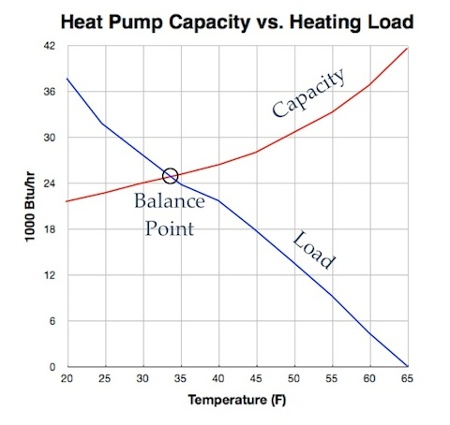

As stated above, the heating capacity of a heat pump drops as the outdoor temperature drops. At the same time, the heating load of the house increases. At some temperature, the capacity is just equal to the load, a temperature we call the balance point. Below that, the load is bigger than the capacity and you need some type of supplementary heat.

As I discussed in the three main sources of home heat article, the supplementary heat is typically provided by electric resistance heat (also called strip heat). But it’s not the only choice. You could pair a furnace with your heat pump and have what’s called a dual fuel system. Or you could put a hydronic coil in the air handler, which is really nice way to provide your supplementary heat.

The supplementary heat source, whether electric resistance or something else, is actually called auxiliary heat. In addition to making up the difference between the load and capacity when needed, it also provides the last kind of heat in this list.

3. Emergency heat

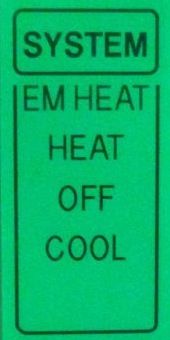

And then there’s that setting on your thermostat you may have noticed. Maybe you’ve even been told to set your thermostat to it whenever it’s cold outside.

Heat pump thermostats have a fourth mode (after heat, cool, and off) called emergency heat, which turns the compressor off and relies on the supplementary heat source for all of your heat. If, as many do, your heat pump uses strip heat for your auxiliary heat, then your heating bills will go up, possibly way up. Don’t do that!

Emergency heat is aptly named. If your auxiliary heat is provided by electric resistance, you should use that setting only when the heat pump is not working and you can’t get any compressor heat.

Now you know all about heat from heat pumps. Or at least the three types of heat provided by conventional heat pumps. I guess I should say something about mini-split heat pumps, but I’ve got to go get some breakfast now so that’ll have to wait.

Related Articles

How NOT to Use Your Heat Pump Thermostat

How the Heck Does a Heat Pump Get Heat from Cold?!

Finding Balance – Heat Pump Heating Load vs. Capacity

What’s the Name of The Outdoor Part of a Heat Pump?

Why Are Heat Pumps So Dumb About Frost?

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 64 Comments

Comments are closed.

So how was breakfast?

So how was breakfast?

Oatmeal with walnuts, raisins

Oatmeal with walnuts, raisins, dried wild blueberries, and maple syrup. Yum!

Oatmeal? What the heck are

Oatmeal? What the heck are you trying to save the planet or something?

Oatmeal is also tasty with a

Oatmeal is also tasty with a few chopped dates, some chopped walnuts, all cooked with the oatmeal. Then sprinkle a bit of cinnamon and sugar or your favorite artificial sweetener on top. Just add milk for a complete taste treat.

I did not know that emergency

I did not know that emergency heat shuts off the heatpump feature. On my upstairs unit where no one lives anymore, I set the thermostat to never turn on the strips. Is that a bad idea? Thanks for the education. 🙂

John, yes, the emergency heat

John, yes, the emergency heat setting bypasses the compressor and runs solely on supplemetal heat. Regarding your disabling of the strip heat for the unoccupied part of your home, it’s probably fine. Just keep an eye on things to make sure the temperature doesn’t go too low and the relative humidity too high. That could lead to mold growth.

John wrote: “I set the

John wrote: “I set the thermostat to never turn on the strips. Is that a bad idea?”

Not a bad idea as long you’re comfortable! Of course, you can always change the setting if it gets cold enough to require supplemental heat.

BTW, which thermostat (model #) do you have that includes such a feature? I often advise clients to install a ‘defeat switch’ on the low voltage wire that controls the strips. At least one state requires an override switch on heat pumps with electric heat strips. I’ve been hoping that would lead t’stat manufacturers to add this feature to the user menu. Another option would be to install an outdoor thermostat that disables the strips above a certain temperature. Many heat pump thermostats include this feature, in which case only an outdoor temperature sensor is required.

David, I bought an ecobee for

David, I bought an ecobee for our heat pump. It has many lockout options, e.g. based on outdoor temperature or on indoor heat differential, etc. I completely locked out the heat strips by setting the outdoor temperature threshold for aux heat to 25F and the minimum compressor outdoor temp to also 25. In Houston it never goes below that so it effectively disabled the heat strips and keeps the compressor running down to 25F should it ever get that cold.

And the nice thing is you can also get a notification when the heat strips are coming on.

Here an article, but it does not show all the settings and thresholds available.

https://support.ecobee.com/hc/en-us/articles/115000414828-How-to-minimize-the-use-of-auxiliary-heat-with-a-heat-pump-on-your-ecobee-thermostat

There are all sorts of ways

There are all sorts of ways of controlling auxiliary/emergency heat (yes, they are both the same thing). I prefer to install an outdoor thermostat that will prevent auxiliary electric strip heat from turning on whenever the outdoor temperature is above the balance point for the heat pump. That way, the homeowner can change the heat setting all they want without accidentally turning on the expensive to operate electric heat.

Also, as long as a brief cool draft is not in a bothersome area of the air distribution system, I disable the auxiliary heat from the defrost control. For second floor attic systems I’ve installed, I’ve never hooked up the auxiliary heat to the defrost relay and have never had a complaint from it, although I have been asked why the system I installed costs less to operate than other systems in the neighborhood.

@John, I just saw Allison’s

@John, I just saw Allison’s reply and realized I missed the part about this being for an unoccupied zone. I concur with Allison’s advice.

As Allison replied, disabling

As Allison replied, disabling the electric strips is fine as long as you monitor the temperature to avoid freezing pipes if and when the heat pump fails. Heat strips are also disabled in cool so an unoccupied house can freeze pipes if inadvertently left in cool mode and a freeze occurs. A thermostat with emergency pipe protection such as the better Honeywell units is a good idea. Or a temperature, water and freeze detector such as the Honeywell Wi-Fi Water Leak and Freeze Detector can save the day.

One of the issues with heat

One of the issues with heat pump systems is that when the thermostat is in the heat mode on a single stage heat pump, the first stage of heat is the heat pump and subsequent stages of heat are auxiliary electric heaters. If the heat pump is not operating, the first stage of heat never satisfies, causing the blower to run constant as the temperature in the house cycles a degree or two lower than set point through the electric heaters. When we switch to the emergency mode, the first stage of auxiliary heat becomes the first stage of heat for the thermostat. This allows the blower to cycle off as the thermostat is satisfied. If emergency heat is being utilized due to a non-operational heat pump, the next thing that should be done is to call for service. If you don’t mind the blower running constantly, leaving the thermostat in the heat mode is not going to do any harm.

There are so many ways to

There are so many ways to increase comfort and reduce energy usage with heat pump systems that don’t cost that much to do. As stated, disabling electric heat in an upper floor is usually not a problem due to residual heat from below floors. Another way to save energy is to install a thermostat that utilizes an outdoor sensor and set the auxiliary heaters to only be functional when the outdoor temperature is a few degrees above the balance point that Allison shows a chart for. My auxiliary heaters are not able to energize unless the outdoor temperature at my heat pump is below 35 degrees. My balance point to maintain the 69 degrees I keep my house is 32 degrees. This way, my wife and I can turn the thermostat down at any time we know we will be out of the house for a while and when we turn the temps back up, the heat pump does all of the work without turning on the expensive to use auxiliary heaters.

Another money saver is to only have the defrost control turn on a single bank of heaters when the heat pump goes into defrost. If a little cool air from the vents once in a while is no problem, just disconnect the wiring from the defrost board to the electric heaters all together. In every home that I have installed attic fed ducting to ceilings, I have never hooked up the auxiliary heaters for defrost and I have never had a complaint. Just a little way to save a few bucks for heating.

as mentioned to Allison in

as mentioned to Allison in another reply above, the ecobee we installed for our heat pump on the 2nd floor does all this for you without needing to install an extra sensor. The weather data is of course pulled from the Internet based on your zip code and the true temperature around your compressor may vary by a few degrees, but for the purpose of deciding to lock out the heat pump it should be good enough.

https://support.ecobee.com/hc/en-us/articles/115000414828-How-to-minimize-the-use-of-auxiliary-heat-with-a-heat-pump-on-your-ecobee-thermostat

I am still undecided about

I am still undecided about using local weather information from the internet to determine proper function of HVAC systems, leaning more toward direct sensor location at the outdoor unit still. In most cases, I suppose it won’t make that much difference, but depending on the location of the outdoor unit and the length of time between weather report changes, it can be a significant factor at times. My heat pump is in the shade most of the day, so the air temperature at the heat pump itself is usually a few degrees lower on sunny days.

I don’t know how much Ecobee

I don’t know how much Ecobee charges for the outdoor sensor, but that’s the way to go. In most cases, the cable used to connect the t’stat with the outdoor unit will have an extra pair of wires that can be used for a sensor.

With Ecobee’s monitoring capabilities, it would be simple to determine your home’s true balance point and then adjust the lockout accordingly. With weather station data, you’ll need to set the lockout higher to account for potential geographic differences as well as lag time between official readings.

As an aside, be aware that a home’s balance point can and will vary with wind. Also, it’s generally lower at the start of heating season, or after periods of unseasonally warm & sunny weather (due to heat stored in home’s thermal mass).

Oh my, where to begin…

Oh my, where to begin…

Quote from the Ecobee support page linked by R.Hawke regarding delta-T Aux staging logic:

“default… relies on feedback… how long it takes to warm up the home. Some heatpumps can take longer than others to warm up and finally start giving heat.”

The idea that a heat pump does not immediately produce heat is incorrect. The issue here is the length of time it takes to recover (‘warm up the home’) presumably from setback. This logic (or at least the explanation thereof) is faulty as it implies the house need not be maintained at steady state. Unless some means is provided to lock out the Aux heat strips during recovery, the use setback with heat pumps is a bad idea. But more worrisome is Ecobee’s reliance on delta-T logic to control strip heat. This harkens back to the days of electro-mechanical stats (bi-metal) that energized strips based on a temperature differential, typically about 2 degrees (determined by relative angles of 1st and 2nd stage mercury bulbs). This contributed to the bad rap earned by early heat pumps! The first generation of digital stats followed this logic but most modern heat pump stats control staging with PID loops that look at the rate of change, thus providing much tighter temperature control.

“its also crucial to know and set the minimum outdoor temperature that the heat pump can run with… This is set at a default 35F (1.7C), so the heatpump will not be used when the weather outside is below 35 degrees Fahrenheit and only aux heat will be used in this case.”

Now this is REALLY dumb! It shows that Ecobee engineers have no clue how to control a heat pump (which is why I never specify Ecobee with heat pumps, or any other after-market stat for that matter). The fact is, heat pumps will operate just fine at much colder temperatures. It’s only a matter of how much heat they produce. For example, the typical single-stage heat pump will produce around 40% of nameplate capacity at 0F at a COP of ~2.0. This means the heat pump is still twice as efficient as strip heat at that temperature. So it makes no sense to shut it down and use 100% Aux heat! Note that some (all?) mini-splits are designed shut down automatically at their minimum operating temperature (typically sub-zero), but it’s a bad idea to use an Ecobee or any other non-OEM stat with a mini-split.

Ecobee has another worrisome setting: “Compressor to Aux Runtime”, which defaults to Auto. I can find no explanation of what “Auto” means here, but the idea that Aux staging should be constrained by runtime is wrongheaded. If a heat pump can maintain the setpoint for hours on end while outdoor temps hover near the balance point, why would we want to energize the strips after some arbitrary period of time? Also, if the user enters a value for this setting (presumably in minutes), I can’t find any explanation as to whether it PREVENTS Aux for x minutes or FORCES Aux after x minutes. Huge difference!

Thermostats vary widely on

Thermostats vary widely on how they handle recovery from temperature setbacks during heating operation of a heat pump. Some try to avoid the use of auxiliary heat, some don’t. Depending on the system characteristics, weather conditions, and thermostat algorithms, temperature setback may or may not save energy, especially night setback when the heat pump is recovering during the worst weather conditions.

My general observation is that third-party thermostat suppliers are generally more clever in terms of user interfaces and remote communication features, but do not understand the basic operating principles of the equipment as well as the equipment manufacturers do. I am clearly biased on this topic, so all I will say is to be careful whose thermostat you use with various types of equipment, especially when you get into higher-efficiency, multi-capacity equipment.

I agree that all high end,

I agree that all high end, multi-function HVAC equipment should use that manufacturer’s proprietary thermostat. After all, the branded thermostat is designed to work with the features on the equipment control boards.

What I am looking for is

What I am looking for is information on HOW aux heat is staged. If my heat pump has 20Kw of strip heat or maybe it has 10 or 15Kw heat strips, will it come on all at once? can it be staged 5,5,2.5 ….. What controls are built in or options available on heat pumps? Would this apply to all brands? thank you

Heat strip staging is a

Heat strip staging is a variable depending on how many controllers are in the mix. The indoor unit may have electromechanical sequencers or digital timers. Some techs will bypass sequencers so that all heat comes on at once. Often there are options at a wiring level on how much comes on first. Then you have the defrost boards in the outside units deciding if the aux heat comes on during defrost or in some cases at all, sometimes based on outside temperature. Of course another variable is the thermostat which should have direct control of emergency heat using the same strips and sometimes direct control of the heat strips if the thermostat setpoint is too far from the current room temperature. Better thermostats do not automatically call for heat strips based on setpoints, but may use a low outside temperature as an enable. Bottom line, it can be complicated with various pieces of the system controlling things. It can also be expensive to run if those heat strips are coming on just because someone raised the setpoint a little, when waiting for the heat pump to ramp up is all that was needed. So the best thing to do is to get a good tech to document the inside, outside, wiring and thermostat setups relative to the heat strips, especially if you are getting much higher than expected electric bills during heating season. I had a neighbor whose heat pump had failed but the heat strips kept the house warm for two months. She had huge bills and still needed to have the heat pump fixed.

Good to hear all these

Good to hear all these options at the stat, Endless almost. To variety one would have to take the system apart if they were not monitoring it at the box, correct? I would hope that the outdoor temps and system COP would be the major indicators for newer system to revert to aux. Or is that with only VS or the higher end products? Thanks, Appreciate your comments.

While every system can be

While every system can be different when it comes to how auxiliary heat is staged, the most common method is that the thermostat will call for auxiliary heat when the temperature drops below the targeted temperature due to the heat pump not being able to keep up. At that point, in most cases, the relay for all electric heat coils is activated, but, time delay relays may only allow so much of the auxiliary heat to energize immediately in order to lessen issues from a power surge. If your thermostat has more than one auxiliary heat mode, and if the auxiliary heating elements are wired for staging, then only a portion of the electric heat will turn on when the temperature at the thermostat falls below the setpoint, and more electric heat strips will be energized if the temperature continues to drop.

Auxiliary electric heat is also energized by the heat pump’s defrost control when the heat pump goes into defrost. Again, it depends on the type of heater strips you have and if they are wired to be staged. I always set up the defrost auxiliary heat control to only energize the smallest electric heating element, if I utilize the auxiliary heat feature for defrost at all.

@Jody, not unlike

@Jody, not unlike conventional electric furnaces of yesteryear, aux heat staging is a function of the particular brand/model of the electric heater kit and air handler, not the heat pump. Only the larger heater kits are staged. For example, Carrier heater kits up to 10kW are single stage, above 10kW are staged. Lennox kits up to 8kW are single stage, above 8kW are staged. The largest kits (typically 20kW for residential) may have as many as 4 stages depending on brand/model.

In most cases, staging is managed by a “sequencer” integrated with the electric heater kit itself. The idea is to avoid hitting the grid with such a a large amperage all at once. Some multi-stage heater kits can be field wired so that staging is controlled by the thermostat, however, this requires a t’stat that supports multi-stage aux heat, typically indicated by terminals marked W1, W2, etc.

Thank you David,

Thank you David,

This was informative. Do most or all the modern multi stage t’stats have more than 2 terminal to handle larger systems aux set ups? If it is limited to 2 stages and the system starts with 10Kw then the next call would trigger the other 10Kw, correct? Do the new variable speed heat pumps and air handlers systems have better capability at larger tonnage? Or are they so proprietary you have no control? Thanks

Since most manufacturers of

Since most manufacturers of HVAC equipment use third party heaters, they are all basically the same. They all have staged heating over 10KW. It is a matter of whether or not the controls being used are designed to handle the staging. Those controls will always be the main thermostat, but could also be outside temperature thermostats. For instance, auxiliary heat on a 15kw system could be set up with the main thermostat only bringing on 5kw of auxiliary heat unless the outside temperatures drop below a preset temperature, when all 15kw would be energized, still sequenced to come on as 5kw at first, then the other 10kw kicking in a few minutes later. There are many ways of setting up auxiliary heat with the use of temperature controls including, but not limited to main thermostat, outside temperature thermostat and/or leaving air temperature sensor.

What is the specific issue you are looking to resolve?

Thank you Robin, I didn’t

Thank you Robin, I didn’t think about the 3rd party heaters being mostly the same. This does line up with my idea and hopes that aux could stage 5>5>5Kw. Yes, I’m getting a better understanding of this part of the systems with these conversations. Options for less energy consumption is my specific issue. Thanks for your help.

Jody, I’ve not personally

Jody, I’ve not personally seen a 15kw heater that was staged in 3 5kw stages. All I have seen are staged 5kw and 10kw. When I run into a 15kw heater that is operating from a single stage aux. stat, and the heat loss of the house doesn’t require more than 10kw, I will suggest having the heaters operated at the 10KW from the indoor thermostat and have the outdoor HP defrost control operate the 5kw stage. This saves energy during defrost.

Great suggestion. Thank you.

Great suggestion. Thank you.

@Jody, too many different t

@Jody, too many different t’stat models to make generalizations. Keep in mind that if marketing literature says ‘multi-stage heat pump,’ that refers to compressor stages (Y1/Y2) not aux heater stages (W1/W2). You have to check the wiring diagram to see if the t’stat terminal strip includes W1/W2. I don’t recall seeing a thermostat with more than two aux heat stages.

If the heater kit has 3 stages, it may be possible to field-wire the first stage to W1 and last two stages to W2 while preserving sequencer staging between the 2nd and 3rd steps. BTW, sequencer staging is accomplished with bi-metal switches that react to heat within the switch itself and the delay is indeterminate and relatively short in duration – on the order of a few minutes. As I said, sequencers are primarily for mitigating grid loading.

Instead of staging the aux heater, you could have a tech simply disable the 2nd stage. You’re likely to find that you never need it. In my experience, aux heater kits are usually grossly oversized. It’s common practice to size heater kits based on a home’s peak heat load in case the heat pump fails. Not only that, the calculated heat load always overstates the true heat load. The largest kit I’ve specified in the last decade is 8kW. You can’t stage kits that size.

Variable speed ‘communicating’ heat pump systems must be paired with the proprietary wall control to get full benefit of all the features, but these systems usually have additional built-in options regarding aux heater control. Each brand/system has its own features so generalities cannot be made. From a controls standpoint, there’s no difference between small tonnage heat pumps and the largest capacity models. That said, the large multi-step kits can’t be used with the smallest air handlers since they don’t move enough air to maintain a safe delta-T.

That pretty much covers it.

That pretty much covers it. Now just manufacture specific I can dig into. Thank you David, I appreciate your time and knowledge. Great education for me.

For years we have been using

For years we have been using the Hairrell Heat Pump Control to lock out the electric resistance heat except when it is needed. The device was resurrected from an older manufacturer, it is simple to install and relatively inexpensive.

I had a dual fuel system

I had a dual fuel system installed in my last house, which worked well. However, there is one significant difference between dual fuel and a heat pump with resistance supplemental heat: the heat pump does not run when the furnace is on. IOW, it performs like Emergency Heat.

To get the best performance for this system, I paired it with a Sensi smart thermostat that would monitor the ability of the heat pump to meet heating demand, and, when it fell short over a period of time, it would switch to the furnace.

Given that gas heat is typically cheaper than resistance heat, I think this saved me some money. However, having to pay a base charge for gas for most of the year may have made it a wash.

On the other hand, in case of winter power outage, I could run the furnace off of my portable generator. Not so with heating elements.

Norman, I, too, have a dual

Norman, I, too, have a dual fuel system in my condo. I leave it set to emergency heat because our homeowners association pays the gas bill and I pay the electric bill. This definitely saves me some money.

@Norman, you bring up a good

@Norman, you bring up a good point… dual-fuel systems are a very different animal from a control standpoint. I’m not familiar with the Sensi stat, but most dual-fuel compatible thermostats switch over to the furnace based on outside temperature (with older stats, a dual-fuel control module was required for this). A few manufacturers, including White-Rogers, now offer dual-fuel compatible stats that support both modes: on-demand switch-over, as you describe, as well as outdoor reset. The control mode must be selected from the installer menu.

By the way, since you (apparently) use natural gas as opposed to propane, I should point out that on-demand is not necessarily the most economical control strategy. Ideally, you want to switch over to the furnace at the ‘economic balance point’, the outdoor temperature below which your furnace costs less to operate than your heat pump (depends on relative cost of gas and electricity, and your equipment efficiencies). For a detailed explanation, see my 2nd comment posted on Allison’s blog linked in first paragraph of the “2. Supplementary heat” section above. Anyone who has a propane dual-fuel system should read that comment!

Norman, you stated, “…there

Norman, you stated, “…there is one significant difference between dual fuel and a heat pump with resistance supplemental heat: the heat pump does not run when the furnace is on…”

Evaporator coils (indoor heat pump coils) must be on the discharge air side of gas furnaces (to prevent corrosive action of refrigerant leaks on gas furnace heat exchangers if on inlet side?) If the gas furnace ran during heat pump operation, high pressure would ensue due to the high temp furnace discharge air entering the indoor coil/condenser coil in heating mode. Thus, the furnace must shut off during heat pump operation.

My HVAC tech told me the same

My HVAC tech told me the same reason. Thanks for explaining it to the rest of the readers.

Do you have more details

Do you have more details about this? Are there configurations for dual fuel systems that enable an air-source heat pump and fuel-based furnace to run concurrently?

There are a few manufacturers

There are a few manufacturers of heat pumps that allow a “bonnet sensor” (temperature sensor) in a dual fuel application. The primary purpose is to allow a defined short burst of furnace heat during defrost. York is one such manufacturer. They control this operation through their defrost board in the outside unit with a specific algorithm to ensure the coil is not overheated. It also requires more wires between the outside unit and the bonnet sensor mounted to measure the indoor air discharge temperature. The system will start the furnace 45 seconds before initiating defrost. If the furnace is not terminated by high indoor discharge air temps before the defrost completion, the furnace will continue running to satisfy the current heat call with the heat pump compressor off. Subsequent heat calls will be heat pump only. When another defrost is needed the furnace will cycle again. The bonnet sensor is an Accessory Kit while the York defrost boards come standard with Bonnet Sensor inputs.

From York’s Accessory Kit instructions:

Bonnet Sensor – Fossil Fuel Mode

“The heat pump may be equipped in the field with an optional indoor air discharge temperature or bonnet sensor. The control does not allow the heat pump and the furnace to operate simultaneously even with a bonnet sensor installed except surrounding a defrost cycle. The control cycles the fossil fuel furnace differently surrounding a defrost cycle depending on whether a bonnet sensor is installed. The bonnet sensor is installed in the indoor unit and is mounted so that it measures the indoor air temperature after the air exits the furnace.” They allow a 109F indoor air discharge temperature during defrost which is the period when the heat pump reverses to cool mode to achieve defrosting of the outdoor coils. Reference pdf “DEMAND DEFROST CONTROL BOARD KIT MODEL 03109137000 FOR MODELS: YZB, HL3B, HC3B YZE, HC5B, & HL5B SERIES”

@Ari, a furance and heat pump

@Ari, a furance and heat pump in a dual fuel config cannot operate simultaneously for the reasons given by Prof. Koldenhott. To get around that, a separate air handler could be ducted in parallel with the furnace, feeding the same duct system (aka ‘pair of trousers to the old-timers, but not typically done for that reason).

A much simpler way to use gas to supplement a heat pump would be to install an air handler plus a gas-fired hydronic coil on the discharge side of the air handler (an air handler is a refrigerant coil + blower). Note that hydronic supplemental heat usually doesn’t make sense with propane since any savings of propane over electric strip heat is unlikely to offset the additional first-cost of boiler + pump + fan coil + controls + labor. In markets with unusually high wintertime electric rates, a propane-fired coil may be the way to go.

I would be careful about the

I would be careful about the term “compressor heat”. Some of us consider that to just be the electrical input to the compressor and do not include the heat transfer to the outdoor coil. Since the heat output from the indoor coil is the sum of the energy input to the compressor and the heat transfer to the outdoor coil, this a significantly different definition.

Roy, I agree. I added the

Roy, I agree. I added the parenthetical caveat just to be careful, as you’ve recommended. I’m not crazy about the term “compressor heat” but am having a hard time coming up with a better one. Thermodynamic heat? Nah, that could be anything. Refrigerant heat? A bit confusing. Outdoor heat? Doesn’t connect to the heat pump.

Got any suggestions?

Pumped Heat

Pumped Heat

D’oh! Of course. Will

D’oh! Of course. Will change that now.

Actually the compressor does

Actually the compressor does add some heat when it is working, typically adding 30-50 degrees to the gas discharged from the compressor. Not sure about the quantity of BTUs this adds. It’s from the heat of compression as well as the heat the electric motor gives off while running. The majority of the heat is absorbed from the outside air as it changes the liquid refrigerant back to a gas.

It is pretty straightforward

It is pretty straightforward to figure out how much of the heat supplied to the house comes directly from the power input to the compressor vs. from the outdoor coil. Since COP for heating is defined as heating capacity divided by system input power (using the same energy units for both), and the primary input power is the compressor power, then (COP-1)/COP is the fraction of heat from the outdoor air and 1/COP is the fraction from the compressor itself. This an approximation since there is some other electrical power consumption such as the fan motors and some energy lost to the outdoor air, but this gives a ballpark number. So if you have a COP of 3, you are getting about 67% of your delivered heat from the outdoor air and 33% from the compressor. For a COP of 2, it is half and half.

Good points. I live in a

Good points. I live in a small ranch and was using a HW boiler system before installing a Mini-Split. Don’t have a heat strip but rely on the oil boiler as backup. When the temp drops below zero, the Mini can have a hard time keeping up, so I have set the boiler set to kick on at 63 degrees, and that seems to work well (Only used 5 gal of oil so far this winter).

I also have a 12 x 25 room I don’t heat and the temp in it can drop to freezing or below which could freeze my baseboard pipes. To handle, I wired the circ pump to a small thermostat with the sensor taped to pipe in crawl-space. I programmed to turn on a 3℃ and off and 4℃ (house is one zone so water from warmer part gets circulated). It has been working flawlessly for 4 years. It only runs for about 10 sec before shutting off, accumulating maybe 7 minutes a cold day. Much lower cost than heat strip and handles maybe 40+ feet of pipe in the unheated room. Humidity has not been a problem. It was a long search to find suitable thermostat, but got one on eBay for about $7 – price has dropped and they now under $3.00 https://www.ebay.com/itm/XH-W1209-Digital-Thermostat-Heat-Temperature-Controll-Switcher-Sensor-Module-Set/303022677330?hash=item468d8f1d52:g:QwgAAOSwrfVZQmfj

It deserves mention that mini

It deserves mention that mini-splits do not have supplementary heat built into them, and therefore should be installed with a separate supplementary heater for when it gets below about 35 F.

The supplemental heat balance

The supplemental heat balance point depends totally on the home’s heat load vs. the heat pump’s capacity curve. With conventional heat pumps, it’s not unusual to see balance points in the mid-20’s. Mini-splits have higher capacity at lower temperatures (than conventional splits) due to the way the compressors are sized relative to their nameplate capacity (a topic for another day) so the balance point will be even lower. So called “hi-heat” mini-splits have even greater low temperature capacity (again, due to the way the compressors are sized). I have several clients in cold climates who can maintain the setpoint without supplemental heat into the single digits. But your main point is well taken. Depending on the particulars, a separate supplemental heat solution may be necessary when heating a whole home with ductless mini-splits. (With a ducted mini-split, inline strips can be installed in much the same fashion as with a conventional heat pump.)

“Mini-splits have higher

“Mini-splits have higher capacity at lower temperatures (than conventional splits) due to the way the compressors are sized relative to their nameplate capacity (a topic for another day) so the balance point will be even lower.”

David — I had noticed that minisplits tend to perform better at low temperatures relative to conventional splits. Can you explain further, or link me to more information about this?

Daiken and Mitsubishi have

Daiken and Mitsubishi have low ambient heating that use variable speed compressors (marketed as “inverter”) and blowers which can ramp capacity from 25% to over 110% coupled with electronic expansion valves and flash injection bypass circuits. All of which allows them to ramp up tremendously compared to conventional compressor systems. The best low temp heating Daiken units are called Aurora and Mitsubishi has H2i hyperheat units. Unlike conventional units that pull lower amps at low ambients, these units pull more amps as they speed up. Both can deliver 100% capacity at 5f and are useable into the negative f temps. Daiken advertises cost savings over natural gas until 14f at which point ng is more efficient. Propane and fuel oil are not in the running.

A recent HVAC school podcast with Jordan Cummings gets into the technology and mentions an option to reuse existing 410a air handlers by adding a eev, thermistors and a control box.

https://www.stitcher.com/podcast/bryan-orr-3/hvac-school/e/58641489

Daiken pdf:

https://www.daikinac.com/content/assets/DOC/White-papers-/BPG-EXTAMB.pdf

Most mini-splits as well as

Most mini-splits as well as some US produced variable speed heat pumps have larger compressors than the nameplate capacity in order to provide additional capacity at low temperatures in heating mode. This would normally be a problem in cooling mode, since the nameplate capacity must fall within certain tolerances in cooling mode, for rating purposes. They get around that by limiting the speed in cooling mode. For example, if a heat pump has a 24k compressor, it would have to be labeled as a 2-ton system if the cooling capacity were allowed to operate at 2 tons. By limiting cooling capacity in software to, say, 15kbtu, it can have a 15k nameplate and still achieve 15k capacity at low temps. The main difference between hi-high and standard models is the size of the compressor.

As an aside… some years ago, a US manufacturer, Hallowell, who did something similar before inverter drive compressors were ubiquitous. The Acadia ‘cold climate’ heat pump utilized a 2nd compressor to boost capacity at low ambient temps. Since the 2nd compressor didn’t operate in cooling mode, they were able to market the system based on the primary compressor’s capacity. Unfortunately, Hallowell and the Acadia didn’t survive, likely due to its high price tag.

I would like to clarify some

I would like to clarify some details about compressor “sizing”. All residential air conditioning and heat pump systems use “positive-displacement” compressors which means they move roughly the same suction volume flow rate under all conditions of heating and cooling for a given compressor speed. So as the outdoor temperature drops for a heat pump, the density of the refrigerant at the compressor suction drops, and thus the mass flow rate of refrigerant drops even if the volumetric flow rate does not drop. As the refrigerant mass flow rate drops, the heating capacity drops, and the compressor power drops. Since the compressor motor is typically sized for cooling conditions, which have a much higher refrigerant suction density than for heating conditions, the motor is thus over-sized during heating conditions if operating at the same speed. For compressors with variable-speed capacity, there is an opportunity to speed up the compressor as the outdoor temperature drops without overloading the motor. Many variable-speed compressor systems take advantage of this opportunity, including some of the newer variable-speed ducted systems.

Halowell’s Acadia cold

Halowell’s Acadia cold temperature heat pump failed due to mechanical issues from overheating. It is a real shame because the concept is sound if enough money could be made available to work out the bugs.

Solar hydronic systems connected to plate heat exchangers work well for boosting heat pump heat on both air to air heat pumps and ground source (geothermal) heat pump systems. Just run a loop from the solar source pumping warmed fluid through a plate heat exchanger that has the suction line loop from the air to air system or the return ground loop line from the ground source heat pump system. The heat transferred from the solar panel source causes the heat pumps to behave like it is a warmer day than it is.

Concur. We have a mini-split

Concur. We have a mini-split in a detached garage. It keeps the garage warm when temperatures drop into the teens. There is no supplemental heat and no heat at all during night time hours. I turn it on when I go to work there in the morning. Even on the coldest day it rapidly heats the garage. The garage is insulated so that must help. On the house open loop geothermal heating, We have just started on our third heat pump in over 30 years and have never had auxiliary electric heat. Aux heat requires more costly electrical supply wiring and has the potential problems mentioned in this larger discussion.

My bill went from $140 to

My bill went from $140 to $400 soon as I switched to heat. Here in central Texas we dont have much of a winter. I can turn my heatpump of at breaker box and it goes back down. My HVAC guy replaced the thermostat. Any other suggestions?

Tommy, I am also in central

Tommy, I am also in central Texas with a relatively big house and my bills this winter have never gotten that large. Hopefully your hvac tech has cleaned the coils and has accurately checked the unit’s charge. He should have taken temperature measurements of the ac lines to determine superheat or subcool. He could measure the unit’s delta t and determine the actual btus the system is producing. If the heat pump is low on charge or its airflow is restricted it will produce low btus and could run two or three times longer to reach setpoint. Excessive use of heat strips is the next issue to investigate. Hopefully he put in a thermostat with an aux heat lockout set to 40f outside temp or below. I believe you should not significantly setback the temp daily and expect it to recover quickly without high heat strip use. Many low cost thermostats will run heat strips at 65f outside temp if the space drops 3 or 4 degrees below setpoint. So a scheduled setback of 10 degrees every day could be costing more than no setback if the heat strips are engaging. I typically run one temp 24×7 which keeps the house’s thermal mass constant, adds comfort and still does not excessively run the equipment. Defrost settings should be checked as well. Excessively long, timed defrosts will cool the heated space and run aux heat every time. We have had a cold wet winter so defrosts are needed, but a unit with demand defrost set properly is much more efficient. If you suspect your tech has cut corners find a better one. If your unit is from a major manufacturer like Trane or Carrier, call one of their dealers. Usually they will be well trained. Of course you need some insulation in the house and the fireplace flues should be closed as well. We do have winter here and January-February are generally the most expensive heat pump months. But you are likely paying too much and shutting off the system will leave you in a cold house.

Turn off the emergency heat

Turn off the emergency heat feature at the thermostat and try to maintain a comfortable temperature rather than heating up a cold house.

Another heat to consider is

Another heat to consider is the crankcase heater — as much as 40 watts — monitored new systems that end up using crankcase heat even in the summer in places with large diurnal swings. It comes on when the temperature drops below 65F and doesn’t go off until temperature hits 88F!

then we have defrost cycles that come on by timers even though there is no frost. Both are easily fixed by aftermarket items but are seriously nonsensical.

If a crankcase heater is

If a crankcase heater is being energized, it is cool enough to adversely affect the refrigerant/oil relationship.

John wrote: “…monitored new

John wrote: “…monitored new systems that end up using crankcase heat even in the summer in places with large diurnal swings. It comes on when the temperature drops below 65F and doesn’t go off until temperature hits 88F!

then we have defrost cycles that come on by timers even though there is no frost. Both are easily fixed by aftermarket items”

Or buy a brand/model with a better controls for these energy-sappers.

Unfortunately, most dealers don’t pay much attention to details like these so the only way the average homeowner can avoid these types of pitfalls is to work with a designer who knows this stuff cold. I encourage clients to invest in circuit-level energy monitoring for HVAC (and more). That makes it easy to spot parasitic loads.

While demand defrost controls

While demand defrost controls do save a bit of energy versus time/temperature controls, they are calculated into the efficiency ratings of the systems. A 14 SEER rated heat pump using time/temperature defrost controls is the same efficiency as is a 14 SEER rated heat pump using a demand defrost control. Changing the time/temperature control to a demand control may increase efficiency by less than half of a percent, it isn’t usually worth the cost to do so. When it comes to efficiency “ratings”, we need not be penny wise and dollar foolish. My heat pump is rated at 14.5 SEER, but due to the way I am using an oversized indoor coil metered with a piston to match the heat pump capacity and have reduced the blower speed to 280 cfm per ton of cooling, the actual efficiency of my system is more around the 11 SEER range, but my home is more comfortable at a higher indoor temperature during the summer months.

@Robin I question the less

@Robin I question the less than half percent as I suspect it is the result of a theoretical calculation rather than monitored data. I will go back to my monitored data and see what I find.

I’ll be interested in what

I’ll be interested in what you find, John. Working with manufacturer’s is where I got the less than half of a percent, .4 SEER increase to be exact. It stuck in my head because that is the same rating difference I am told that removing the crankcase heater and replacing it with a shunted, single pole contactor makes. For manufacturing purposes, those minor SEER boosts can make the difference between getting 13 SEER from a 12.7 SEER condensing unit of having to rework a model line. There are many ways to play with the SEER value of a system that don’t always actually benefit the end user. After all, we can obtain a higher SEER rating from a system using a third party indoor coil even if that coil is the exact same coil provided to the outdoor unit manufacturer under the outdoor unit brand name. The difference in the SEER ratings are only due to the differences in the allowances for testing the system components. This is one of the reasons Lennox International will never bring their ADP coil division under the Lennox name.