Two Ways to Change the Heat Pump Balance Point

So we’ve looked at a simple way to estimate the heat pump balance point. If you also read the comments of that article, you should be aware that there’s more to the actual balance point than what I wrote in the article. Today, though, let’s look at two factors that can affect the balance point.

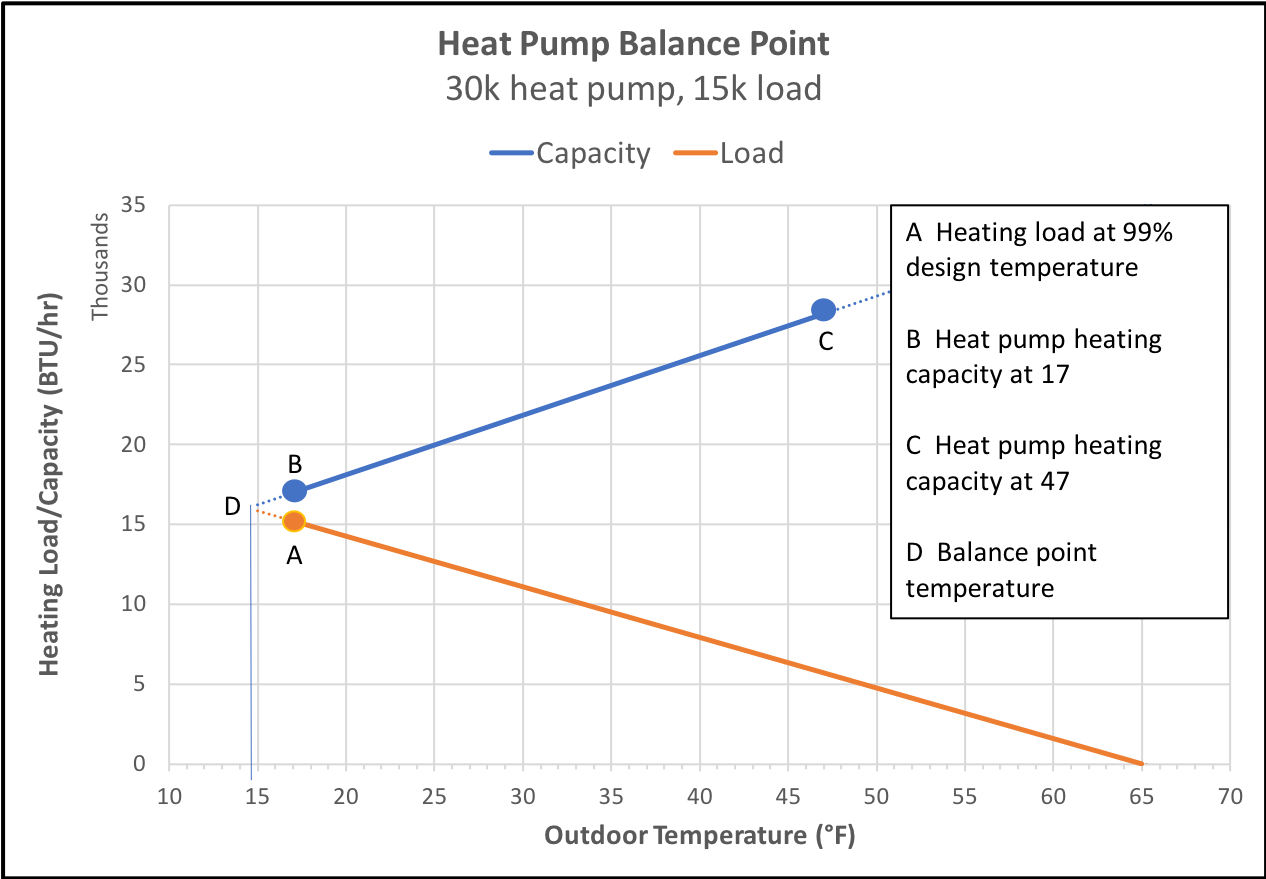

First, recall that the simple method to find the balance point involved plotting the heating load of the house and heat pump capacity on the same graph. Using two data points for each and assuming a linear relationship between load/capacity and outdoor temperature, we had two straight lines. The temperature where they cross is the heat pump balance point. It tells you at what temperature the heat pump is just able to keep the house at the indoor design temperature (normally 70 °F).

Now we’re ready to take it further.

The effect of equipment size on balance point

In that last article, I used an example from a load calculation we did for a home in New Jersey. The heat pump balance point, using the method described, was 25 °F. The load at the design temperature was about 15,000 BTU/hr and the heat pump used in the example was one that’s nominally rated at 18,000 BTU/hr. So to change where the two lines intersect, we can change either line, the load or the capacity. Let’s start with the capacity.

Instead of a heat pump with a capacity of 18,000 BTU/hr (1.5 ton), let’s put in a heat pump with a nominal capacity of 30,000 BTU/hr (2.5 ton). Just thinking through this, you should be able to see that more capacity will result in a lower balance point.

The graph below shows how to find it.

The orange line here is identical to the one in the previous graph. We haven’t done anything to change the heating load. The blue line, however, has moved up as the capacity is higher at both of the temperatures we’re using.

For this setup, the heat pump can provide all the heat needs down to and even a little below the design temperature. To find the balance point, we have to extrapolate the two lines to find the intersection, which is at about 15 °F.

The effect of heating load on balance point

Likewise, we could change the other part of the graph, the heating load, to change the balance point. If you have an existing home and want make it more comfortable and energy efficient by doing some air sealing and insulating, the house won’t need as much heat. The house in our example initially had a heating load of about 15,000 BTU/hr. Let’s say we add some insulation, make it more airtight, and seal the ducts. Now the load drops to about 10,000 BTU/hr, and we use that as our design temperature heating load point on the graph.

But wait! There’s more. In the last article, I assumed that zero load happens at 65 °F. In many homes it may well be lower, especially if the home is airtight and well insulated. In such a home, the load could easily be zero at 55 °F. That means the heat doesn’t come on until the outdoor temperature is 55 °F.

Here’s what the graph looks like now.

The blue line is the capacity of the 1.5 ton heat pump, same as in the first graph, the one in the other article. But now the orange line is lower, and the two intersect at 17 °F now instead of 25 °F. So we’ve dropped the balance point 8 °F by making the home more efficient.

This home now has a balance point right at the design temperature. That means it doesn’t need any supplemental heat.

The downside of lowering the balance point

Lowering the balance point is great for heating. If that were the only consideration, we could make the house as efficient as possible and then put in a heat pump big enough to ensure the balance point is below the design temperature. The problem, however, is that oversizing can have a deleterious effect on cooling, especially in humid climates. You need equipment sized close to the cooling load to get good dehumidification. Even in a dry climate, oversizing affects comfort negatively because the system comes on and goes off more frequently (short-cycling).

Normally, when you make the house more efficient and have a lower heating load, as in the last section, you also put in a smaller heating system. For conventional fixed-capacity equipment, of course, the smallest heat pump you’ll find is 1.5 ton. So in that example, we’ve already got the smallest heat pump of that type and can’t go smaller. As a result, the system will short-cycle most of the time.

Now the heat pump balance point is demystified a bit more for you, I hope. Of course, there’s also the issue of what the actual balance point is and what kind of equipment you can use to get a low balance point and not have short-cycling. But those are topics for another time…because I need to go watch this video of a panda rolling in the snow.

Related Articles

A Simple Way to Calculate Heat Pump Balance Point

The 3 Types of Heat From Heat Pumps

Finding Balance – Heat Pump Heating Load vs. Capacity

How the Heck Does a Heat Pump Get Heat from Cold?!

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 21 Comments

Comments are closed.

Interesting, but not very

Interesting, but not very unusual as the urge to oversize is the opioid for contractors and supply house gurus of design. Recently ran across a totally screwed up heat pump install when called in to determine why their electric bills were outrageously high. 3.5-ton heat pump with 15-kW on board aux heat. A single 14″ flex duct, 30% compressed, to serve the much larger 1st floor. 2nd floor ducts, all flex, also pinched and compromised flex duct with one room needing another supply. Man-J calc revealed total heat load was 105,089-BTUH and cooling load 67,355-BTUH. The 14″ flex was to serve the 1st floor heating load 84,722-BTUH & cooling load 53,534-BTUH. Best they could attain on design day temps was 55F indoors. What balance point?!? We did resolve the issues.

I believe the growing

I believe the growing consensus from everything I have been reading is that in humid climates, adding a standalone ducted dehumidifier is the best solution for almost year round humidity control. I have chosen the Aprilaire 70 pint as standard for all of my hurricane resistant homes in coastal NC. My blower door numbers are under .4 ACH at 50 Pascal so I am able to downsize my HVAC units. With that, my latent capability drops along with the sensible so having the dedicated dehumidifier as backup solves the problem. Also, with four swing months with no HVAC required at all, this lets me control humidity year round, even in winter months when people generated humidity is trapped in the ultra-tight house. With humidistat set at 45%, in summer we can run AC at 78 degrees and be comfortable while not working the system so hard (Arizona dry heat thing). This saves electricity that can be used to run the dehumidifier when needed.

Would a heat pump or air

Would a heat pump or air conditioner with a hot-gas reheat function (AFAICT from manufacturer docs, AAON offers that feature on their CB/F1 HP/AHU pairing) be a sensible alternative to a separate dehumidifer in this circumstance, or is the extra refrigerant piping and valves for HGRH considered a prohibitive level of complexity for a residential application compared to having a standalone unit?

For residential purposes, a

For residential purposes, a heat pump system with the largest indoor matching coil that is properly sized for cooling, utilizing a variable speed blower set to below 300 cfm per ton, is going to handle most humidity issues. For ROI purposes, it is beneficial to just use a 5kw bank of electric heat that is already in the system to cause the cooling to system to operate longer cycles for extreme dehumidification times. With a standard cooling system using a psc blower motor, I’ve even built a fire in our wood stove on low heat, high humidity days to dry the house out.

Yet another reason to go with

Yet another reason to go with hydronics instead of a forced-air furnace for backing up a heat pump with gas, I suppose? 🙂

The main reason for going

The main reason for going with either hydronic or forced air furnace is dependent on what is already in the house. If there is an existing hydronic system with a separate ducted cooling system, it is best to utilize a heat pump through the ducting system as the primary source of heat while using the existing hydronic system for auxiliary. If there is no existing ductwork, it is practical to consider Mini-Split heat pumps for cooling and primary heat source. We need to take every situation on its own merits. There is no one better way.

Yeah, existing hardware can

Yeah, existing hardware can skew things one way or another when you’re not starting from a clean sheet, of course 🙂

Especially for the New Jersey

Especially for the New Jersey example being used, I agree that heat pumps “MUST” be sized for the cooling/dehumidification needs and any additional heating be accomplished with an auxiliary source.

For change out situations, we never want to increase the cooling capacity because the ductwork was simply not designed to do so. Increasing a heat pump’s capacity to obtain a lower balance point will more than likely cause head pressure issues during the heating season due to the duct sizing. We can decrease the amount of air across the indoor evaporator coil but we cannot decrease the amount of air across the indoor condensing coil without raising the head pressures.

As usual, a great topic with

As usual, a great topic with expert insight by Allison. For me, this article raises 3 key points for reflection.

1. I will start with the “other balance point” which is addressed in the last slide. This balance point is when the internal and solar gains are equal to the heat loss of the enclosure. In very highly-insulated and airtight structures — even with efficient appliances and lighting — the need for space heating to engage can be in the 40 to 50 degree range. My home is between 45 and 50 depending on solar availability. One important item to remember here is that when your heat pump will perform at it’s very best, you don’t need it. And that turns out to be a lot of hours. I suspect this is skewing and overpredicting the savings of the heat pump when folks use hand calculations or simple models.

2. This raises the whole issue of the standard heating design load procedures and practices. These calculations are to assume there is no residual solar from the previous day, no electrical gains from appliances, lighting, or other devices, and no people in the home. If this is true then the arguement in the first item goes away and the line in that graph goes back to where Allison started. While I appreciate why people don’t want to fall short on a cold, winter night, the highly-efficient home just doesn’t require much extra heat to stay comfort, just turn the lights and appliances back on.

3. Finally, as Allison is pushing us to do, we need to rethink how we match (or not) the loads and equipment. Certainly oversizing cost money and can cause poor performance, especially in the cooling mode. However, many of the newer heat pump technologies can achieve higher efficiencies under part-load conditions.

So what’s the point of this long comment.

In the end, it seems clear this issue demands some changes in thinking and practice and in the mean time some good experience guided engineering judgement.

@Patrick, great comment. Let

@Patrick, great comment. Let’s add some fuel to that…

It’s not just the absence of an actionable load at milder temps that skews savings analyses. As I noted in a comment on the previous article, Manual J significantly overstates the other end of the load curve (i.e., the design load), especially for beyond-code homes as internal & solar gains begin to loom large relative to enclosure losses. So it’s no surprise that most of the savings analyses I’ve reviewed from well-meaning HVAC dealers grossly overestimate baseline heating & cooling costs. Although this affects comparisons among other types of heating equipment, heat pumps are unique since their operating efficiency depends on outside temp.

The way I get around the ‘mild-temperature bias’ is to come up with a seasonal (average) COP that reflects a more realistic load curve (adjusted downward at both ends) for a given home. The analysis is ultimately a judgment call, informed by having lived with and analyzed heat pump performance for 38+ years, including 20 years of experience with energy modeling and load calcs for beyond-code homes, supplemented by a fair amount of in-situ data. The problem is, I have no clue how to turn all that experience into a standard procedure or algorithm!

@Patrick, one more

@Patrick, one more observation… You wrote: “…many of the newer heat pump technologies can achieve higher efficiencies under part-load conditions.”

The implication is that it’s OK to oversize inverter based heat pumps. I disagree. What is true is that newer heat pump technologies (especially hi-heat mini-splits) have significantly greater heating capacity at design conditions than conventional heat pumps.

As it turns out, the topic that it’s OK to oversize modulating heat pumps came up just this week over in Home Energy Pros forum. Here’s my rebuttal:

“This is apparently a commonly held belief. The problem with that is that it robs the system of it’s full dynamic range over the nominal design load (and the benefits that entails). A customer pays a premium for a system that can load-match, but gives up some (or all) of that away if the system is oversized.

“Keep in mind that variable capacity equipment can’t modulate to zero (not even close), so even with a ‘modest’ amount of oversizing, the system ends up operating at minimum capacity for the vast majority of hours, thus losing any ability to load match. This issue gets particularly nasty with multi-splits, which already take a serious efficiency hit due to capacity mis-match during single zone calls. And with air-zoned systems, you need the full dynamic range of the equipment (and then some) to manage single-zone and (sometimes) two-zone calls. In short, oversizing a zoned system can lead to serious performance issues.

“I also take issue with the notion that variable capacity equipment is always more efficient at part-load. Blanket claims like that lead to poor design decisions by specifiers and designers who are not inclined to dive deep into in-depth equipment performance data.”

Thanks, David! I should have

Thanks, David! I should have been more careful with my last item. What a great response. This is exactly what is needed, solid engineering driven by experience. And I might add, experience that includes performance feedback. We need more David’s and Allison’s!

Mini Split heat pump systems

Mini Split heat pump systems allow for a lower balance point because they are more effective heating at lower temperatures. In the area I mostly deal with, Eastern PA, New Jersey, Delaware, Maryland and Northern VA, high heat Mini Split systems are effective enough to not require auxiliary heat.

We size for cooling only.

We size for cooling only. The heat takes care of it self. In Florida is more important to control humility. I have seen homes with heat pumps that where over sized for heat handling server mold issues. Home owners get turning it colder in the summer beside of the humility and the mold issue gets worse. And we only heat about two weeks per year.

We’re have a condo with overt sized units they where heat loaded for max occupation which is rare, many units have mold issues, so installed units with eco fans and humidastats so they dehumidifier better under lower load.

Being a hvac tech in the

Being a hvac tech in the Tampa area we don’t see temps that low to worry about balance point. That being said once your running any brand of heat pump regardless of effiencey the outdoor coil will start strat freezing at 23 to 25 degrees. Depending on tonage you will always need at least a 15 kw heat strip to moderately temper the supply air while the unit is running in defrost. Northern climates are not the best for heat pumps the average defrost cycle per 90 minutes of run time is about 45 minutes which means for example a 4 ton system with say a 20 kw heat strip will be pulling roughly 65 amps every 45 minutes in a defrost. Actually costing you double the electric versus a straight heat strip heat. Simple solution if your North of Washington DC stick your gas furnace.

While you’re correct that

While you’re correct that balance point isn’t going to matter much in Florida as that’s a heavily cooling-dominated climate, I seriously question your sizing advice regarding strip heat. Electric duct (strip) heaters put out 3413 BTU/h/kW, so you’re basically saying that for the OP’s house, which can be heated by a 5kW strip heater (slightly over 15kBTU) by itself, that the heat pump (a nominal 18kBTU unit) is going to require another 22kBTU (at a minimum) to be fed to it to defrost the outdoor coil? That sounds like a fair bit of an oversize…how is that heat pump running over nominal cooling capacity during defrost operation?

Sidenote: how *do* mini-splits handle reheat during defrost, anyway?

Apologies for my own

Apologies for my own overharried math! My prior post should state that the heat pump is apparently needing an extra 12kBTU atop its 18kBTU capacity, not 22kBTU!

“how *do* mini-splits handle

“how *do* mini-splits handle reheat during defrost, anyway?”

Mini-split defrost cycles are normally done by reversing the heat flow, pulling heat out of the house and into the outdoor coil while defrosting. That is normally done with the indoor unit’s blower at it’s lowest speed, with the vanes directed downward (for wall-coil types) to minimize the potential comfort issues of blowing cold air during the heating season.

I have a couple of comments

I have a couple of comments as a manufacturer of this type of equipment.

Modern air conditioning systems do not really sacrifice much latent capacity during equipment cycling as long as you don’t use continuous fan or extended fan-off delay times.

If you want to size heat pump equipment more towards the heating requirements in less moderate climates to reduce auxiliary heat, I suggest that you look at multi-capacity systems that will run at lower capacities (less cycling) during cooling. There are a lot of benefits to this in terms of lower noise and higher efficiency, even without heating considerations.

There is nothing magical about minisplit heat pump systems having more heating capacity. They do it by having a variable-speed compressor that you can “over-speed” at low ambient heating conditions without overloading the motor. Most U.S. manufacturers of variable-speed compressor heat pumps for ducted split systems have the same feature with the same benefit. It just costs more than the lower efficiency equipment.

There is nothing “magical”

There is nothing “magical” about anything in the HVAC industry; it’s all a matter of physics. Physics dictates that heat energy utilized for condensing water vapor into a liquid cannot also be used to lower the temperature of the air at the same time. When energy is used to remove heat from the air, that same energy cannot also be condensing water vapor in the air at the same time.

Other factors that allow Mini-Split systems to heat (and cool) more effectively is a lack of loss/gain of heat through the ducting system.

“There is nothing magical

“There is nothing magical about minisplit heat pump systems having more heating capacity. They do it by having a variable-speed compressor that you can “over-speed” at low ambient heating conditions without overloading the motor. Most U.S. manufacturers of variable-speed compressor heat pumps for ducted split systems have the same feature with the same benefit. It just costs more than the lower efficiency equipment.”

A really MAJOR difference with cold climate mini-split capacity and efficiency is the use of vapor injection scroll compressors where the vapor injection (not just the compressor speed) is optimized for greater capacity & efficiency within the targeted temperature bands. This is WAY more than mere modulation of compressor speed.

SFAIK there are still no US vendor of ducted split heat pump products using that type of compressor technology (though Carrier has at least experimented with it using prototype Copeland vapor injection compressors.) It’s almost as if the US manufacturers are ceding the cold climate heat pump market to the Asian vendors, who are already on 3rd and 4th generation products using that technology, and not just in ductless mini-splits. There are several VRF full sized air handler options that can be paired with cold climate outdoor units from several vendors, just not any from US vendors.