Joe Lstiburek’s Ideal Double-Stud Wall Design

Joe Lstiburek called me last week to set the record straight. I had written an article about a study of moisture in double-stud walls in a Massachusetts home, and his company, Building Science Corporation (BSC), had done the research as part of the Building America program. They found elevated moisture content in the cold, exterior sheathing, and Joe wanted to make sure everyone knew, “I would never build that wall because I consider it too risky.”

The BSC study redux

The reason he called is I that I hadn’t done my job as a journalist. Of course, I’m not really a journalist; I just play one in this blog. But that doesn’t absolve me from the duty to dig deeper, especially when I ascribe a conclusion to a person when that conclusion came from third party sources. In this case, the conclusion was that buildings are more robust than we give them credit for, a statement I had initially ended that article with.

Because of that conclusion and because I hadn’t made it clear that BSC only monitored the project, some readers had the mistaken impression that BSC had at least endorsed, if not designed, that double-stud wall. As mentioned above, Joe considers that wall too risky, and the excessive moisture content in the exterior sheathing confirms his misgivings. Although the sheathing wasn’t damaged when they deconstructed the wall sections after three years, the amount of moisture they saw during winter and spring was a concern.

As for the debate about where the moisture came from, Joe said it’s coming from inside. The perfect correlation between indoor relative humidity—low in winters 1 and 3, high in winter 2—and sheathing moisture content—also low in winters 1 and 3, high in winter 2—indicates that the moisture is from indoors.

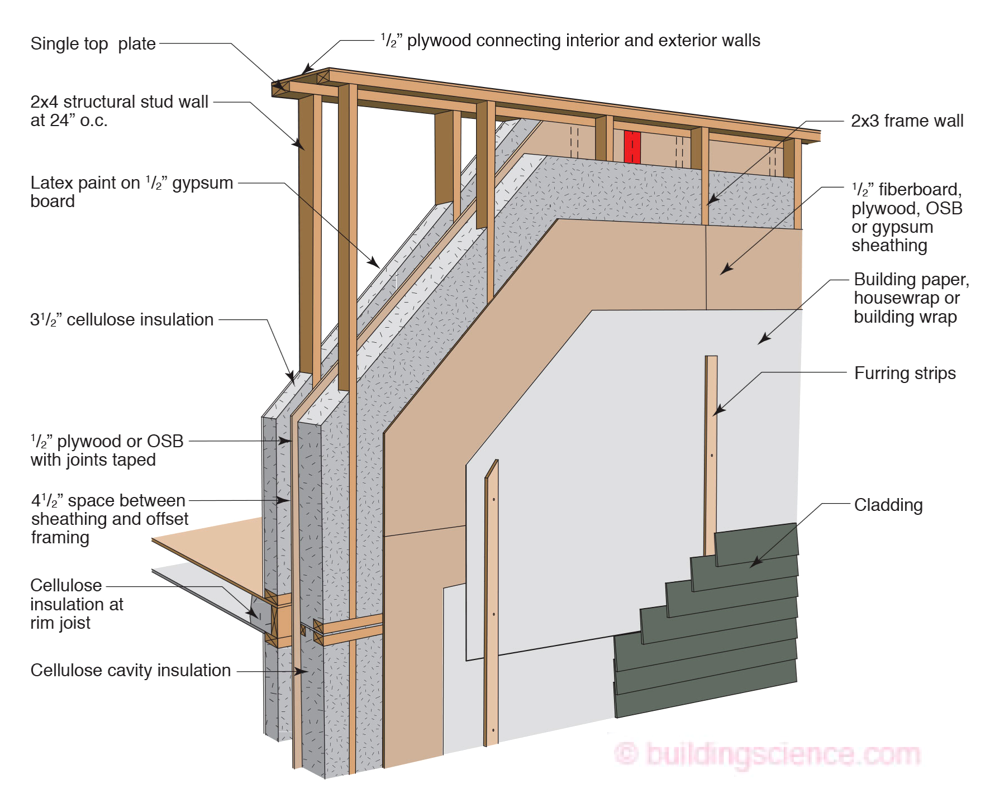

“None of this is unknown,” Joe told me. “None of it is a surprise. None of it, which is why on our website, we recommend don’t build this wall; build ’em this way. (See diagrams above and below.)

The problem is the lack of adequate vapor control. Both cellulose and open-cell spray foam, the two types of insulation they looked at, are Class 3 vapor retarders (1-10 perms). With lots of insulation in the walls, twelve inches in this study, the exterior sheathing stays colder. Cold materials are generally wetter than warm materials.

“The wall design I’m talking about solves the problem of inside moisture and it solves the problem of outside moisture,” Joe said.

Lstiburek’s ideal double-stud wall design

The diagram at the top of the article shows Joe’s ideal double-stud wall design. (For more details, see High R-Value Wall Assembly: Double Stud Wall Construction on the BSC website.) It’s got two layers of framing, which is why it’s called a double-stud wall or double-wall construction, but there’s an important difference between his wall and the one in the BSC study. He specifies a layer of OSB or plywood on the outside of the inside wall when using an air permeable insulation like cellulose or fiberglass.

That extra sheathing serves as the primary air control layer as well as the vapor control layer. That method works in a cold climate, like the climate zone 5 where the BSC study took place. It also works in other climates. “Plywood or OSB work in every climate zone,” Joe said. “Both of them act as a rigid, smart vapor retarder and air control layer.”

Some builders in cold climates put a layer of 6 mil polyethylene inside a double-stud wall instead of the OSB or plywood that Lstiburek prefers. I asked Joe for his thoughts on that technique: “In terms of the physics, it’s great. In terms of practicality, it’s a very fragile way of doing things. That’s why I like sheet goods. We did this in the early ’80s and it was difficult to build.”

Another thing Lstiburek likes is to have the structural part of the double-stud wall be the interior wall. “I also think it’s colossally stupid to have the second wall of a double-stud wall be on the inside of the structure. That’s an incredible waste of floor area and materials and very, very difficult from an airtightness perspective,” he said. In the BSC diagram directly above, you can see the exterior wall is clearly outside the structure.

On the exterior of the wall, he specifies a vented rainscreen to aid drying. The first diagram shows furring strips, but any method that provides at least a 3/8″ gap should work. A ventilated cladding, like vinyl siding, would also work.

Lstiburek’s ideal double-stud wall has all the thermal, air, and vapor control that it needs to make the wall perform well and avoid moisture problems. “I think the walls that I’m recommending are not risky, regardless of whether we’re talking about interior or exterior moisture,” Joe said.

According to Lstiburek, the current hullabaloo over double-stud walls is a distraction: “Here’s what’s frustrating about this: We figured all this stuff out thirty years ago!”

External Resources

BSC: High R-Value Wall Assembly: Double Stud Wall Construction

BSC: High R-Value Wall Assembly: Double Stud with Spray Foam Wall Construction

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He also has written a book on building science. You can follow him on Twitter at @EnergyVanguard.

Related Articles

Is This the End of the Double-Wall, Cold Sheathing Scare?

Fiberglass Insulation Manufacturer Gets Serious About Installation

The Pen Test — A Control Layers Tool for Architects and Contractors

Diagrams of double-stud wall used with permission from Building Science Corporation.

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 32 Comments

Comments are closed.

To me the big question is,

To me the big question is, "Why didn’t Carter Scott build his walls this way?" <br /> <br />I’ll speculate that he’s like me and looking for a holy grail wall that is even simpler and cheaper yet robust enough. Carter Scott’s wall is simpler because it uses a built-in air control layer that doubles as the WRB. That saves the cost of one layer of sheathing, and the labor to install it. <br />It’s really just like the Shirley wall/roof, which does show some promise: http://www.greenbuildingadvisor.com/blogs/dept/musings/dense-packed-cellulose-and-wrong-side-vapor-barrier <br /> <br />If you believe that the Shirley Wall will work in practice, you are buying into Bill Hulstrunk’s theory that dense packed cellulose will (through capillary action) pull moisture back to the heated space as fast as the vapor drive mechanisms push it out to the cold sheathing. <br /> <br />The present BSC report indicates this "hygric redistribution" is NOT happening quite fast enough.

What about Stagering Studded

What about Stagering Studded walls? <br /> – Cost comparison to double studded walls? <br /> – normal studded walls? <br /> – R-value comparison? <br /> – Effect on things like electrical wiring, headers etc? <br />What’s the most cost effective method to build properly insulated walls?

This is always an interesting

This is always an interesting topic. I would, however, offer a suggestion that term "double-wall construction" be clarified to be "double-stud wall construction" as double-wall construction has been used for years to mean a studded wall with two surfaces. Single wall is what we used in areas like Hawaii were the mild climate did not require heating and thus insulation. http://www.atlasconstruction808.com/what-is-the-difference-between-single-wall-and-double-wall-construction/

This is a great topic, I

This is a great topic, I would agree with pushing the "double wall" to the exterior of the structure not only saves "interior space", but also reduces the amount of thermal transfer through the floor system. This wall design DOES pose challenges on what type of foundation system AND requiring roof trusses to align perfectly on top of the structural studs.

I’m not surprised either that

I’m not surprised either that winter moisture drive is an issue in this cold climate with this wall. Wouldn’t a continuous / taped / airsealed "smart vapor retarder" placed in the inside face of the inner stud wall, coupled with a continuous mechanical ventilation (esp in the winter) solve the issue? Those membranes need care for install and need to be unbroken (think Passive House "red line" rule), but its just a little pre-planning with the framers. And if the house is below 5.0 ACH50, mechanical ventilation is required. A "good-enough" system would be constantly exhausting that moist air. I prefer passive methods, so I like Joe’s wall too, but it might be unrealistic to think our building envelopes alone can handle our modern thermal comfort expectations and the challenges that brings. Great article, great topic.

To me the big question is,

To me the big question is, “Why didn’t Carter Scott build his walls this way?”

I’ll speculate that he’s like me and looking for a holy grail wall that is even simpler and cheaper yet robust enough. Carter Scott’s wall is simpler because it uses a built-in air control layer that doubles as the WRB. That saves the cost of one layer of sheathing, and the labor to install it.

It’s really just like the Shirley wall/roof, which does show some promise: http://www.greenbuildingadvisor.com/blogs/dept/musings/dense-packed-cellulose-and-wrong-side-vapor-barrier

If you believe that the Shirley Wall will work in practice, you are buying into Bill Hulstrunk’s theory that dense packed cellulose will (through capillary action) pull moisture back to the heated space as fast as the vapor drive mechanisms push it out to the cold sheathing.

The present BSC report indicates this “hygric redistribution” is NOT happening quite fast enough.

What about Stagering Studded

What about Stagering Studded walls?

– Cost comparison to double studded walls?

– normal studded walls?

– R-value comparison?

– Effect on things like electrical wiring, headers etc?

What’s the most cost effective method to build properly insulated walls?

I’m curious as to how the

I’m curious as to how the windows fit into these walls sections. Are there details for that?

This is always an interesting

This is always an interesting topic. I would, however, offer a suggestion that term “double-wall construction” be clarified to be “double-stud wall construction” as double-wall construction has been used for years to mean a studded wall with two surfaces. Single wall is what we used in areas like Hawaii were the mild climate did not require heating and thus insulation. http://www.atlasconstruction808.com/what-is-the-difference-between-single-wall-and-double-wall-construction/

This is a great topic, I

This is a great topic, I would agree with pushing the “double wall” to the exterior of the structure not only saves “interior space”, but also reduces the amount of thermal transfer through the floor system. This wall design DOES pose challenges on what type of foundation system AND requiring roof trusses to align perfectly on top of the structural studs.

I realize this whole

I realize this whole discussion is about double-stud-wall construction, but its recurrence would seem to endorse it as the BSC-recommended wall type. But it would seem that the single-stud-wall type (http://www.buildingscience.com/documents/enclosures-that-work/high-r-value-wall-assemblies/advanced-frame-wall-construction?topic=doctypes/enclosures-that-work/etw-high-r-value-enclosure-assemblie) is truly the BSC-endorsed type (and the one Joe highlighted on his barn).

<b>Kevin D.</b>:

<b>Kevin D.</b>: I haven’t talked to Carter, but I think you probably correctly answered your question. The wall he built was less expensive and easier to build than the one Joe recommends. <br /> <br /><b>Scott</b>: Staggered stud walls are similar to double-stud but generally don’t get as much insulation. They both provide a thermal break as the studs don’t go all the way through, but neither is as good as continuous exterior insulation with foamboard or mineral wool. <br /> <br /><b>Thomas D.</b>: I’ve thought about the two terms and have wondered why they’re used interchangeably. There does seem to be a preference for double-stud walls, though. I haven’t decided which I like better, although I did use double-stud wall for this article. The link you provided didn’t offer any help as to what you mean by double wall. I assume you’re not talking about staggered stud, but I really don’t know how what you call "a studded wall with two surfaces" is different from the double-stud wall I’ve been writing about. <br /> <br /><b>Doug K.</b>: Yes, putting a Class 2 vapor retarder of any type on the inside wall would do the trick. You correctly point out that a membrane on the inner surface could be subject to damage. That’s why Joe says, "I’m a sheet goods guy." <br /> <br /><b>Lee</b>: I wrote an article last year about a Passive House builder (Hammer & Hand) that made their <a href="http://energyvanguard.com/blog-building-science-HERS-BPI/bid/77054/Passive-House-Builder-Hammer-Hand-Helps-You-Fight-the-Devil">best practices manual</a> available to anyone who wanted it, and it contains good details for how to do that. <br /> <br />

<b>Dave</b>: Yes,

<b>Dave</b>: Yes, Joe prefers continuous exterior insulation to double-stud walls. He did it on his own house, which you can read about it in this great article he wrote: <br /> <br /><a href="http://www.buildingscience.com/documents/insights/bsi-056-leiningen-versus-the-ants-redux"><i>Leiningen versus The Ants Redux</i></a> <br /> <br />.

I’m not surprised either that

I’m not surprised either that winter moisture drive is an issue in this cold climate with this wall. Wouldn’t a continuous / taped / airsealed “smart vapor retarder” placed in the inside face of the inner stud wall, coupled with a continuous mechanical ventilation (esp in the winter) solve the issue? Those membranes need care for install and need to be unbroken (think Passive House “red line” rule), but its just a little pre-planning with the framers. And if the house is below 5.0 ACH50, mechanical ventilation is required. A “good-enough” system would be constantly exhausting that moist air. I prefer passive methods, so I like Joe’s wall too, but it might be unrealistic to think our building envelopes alone can handle our modern thermal comfort expectations and the challenges that brings. Great article, great topic.

Allison, I’m ever more

Allison, I’m ever more impressed by and appreciative of your ability to condense, translate and communicate complex concepts for us mere mortals in the building community. Yep, occasionally an error like this will be made, and I’m very impressed by the way you handled it expeditiously and professionally. With this blog post you earn even more respect and gain even more credibility from your peers. Well done. <br /> <br />As for the double-wall? Nice, but there are so much easier ways to solve both thermal and moisture problems. Anyone interested in learning about materials and techniques that work where it’s seriously cold should go the CCHRC website (Cold Climate Housing Research Center, CCHRC.org) Look at the project in Galena and the brilliant wall construction they used for affordable housing. <br /> <br />Keep up the great work, Allison. We look forward to every blog post.

Allison, what is holding the

Allison, what is holding the interior wall insulation from falling into the 4.5 inch air space?

I’m curious as to how the

I’m curious as to how the windows fit into these walls sections. Are there details for that?

<b>Mac S.</b>:

<b>Mac S.</b>: Thank you, sir! I have to make it simple enough so I can understand it. Here’s a direct link to the Galena page at the Cold Climate Housing Research Center: <br /> <br /><a href="http://www.cchrc.org/galena-prototype-home">Galena Prototype Home</a> <br /> <br /> <br /><b>Edgar</b>: Unfortunately the BSC diagrams don’t show the bottom of the wall details, but there would need to be OSB or plywood at the bottom, connecting the outer double-stud section to the bottom of the structural wall, maybe using a ledger. <br /> <br />

I realize this whole

I realize this whole discussion is about double-stud-wall construction, but its recurrence would seem to endorse it as the BSC-recommended wall type. But it would seem that the single-stud-wall type (http://www.buildingscience.com/documents/enclosures-that-work/high-r-value-wall-assemblies/advanced-frame-wall-construction?topic=doctypes/enclosures-that-work/etw-high-r-value-enclosure-assemblie) is truly the BSC-endorsed type (and the one Joe highlighted on his barn).

Kevin D.:

Kevin D.: I haven’t talked to Carter, but I think you probably correctly answered your question. The wall he built was less expensive and easier to build than the one Joe recommends.

Scott: Staggered stud walls are similar to double-stud but generally don’t get as much insulation. They both provide a thermal break as the studs don’t go all the way through, but neither is as good as continuous exterior insulation with foamboard or mineral wool.

Thomas D.: I’ve thought about the two terms and have wondered why they’re used interchangeably. There does seem to be a preference for double-stud walls, though. I haven’t decided which I like better, although I did use double-stud wall for this article. The link you provided didn’t offer any help as to what you mean by double wall. I assume you’re not talking about staggered stud, but I really don’t know how what you call “a studded wall with two surfaces” is different from the double-stud wall I’ve been writing about.

Doug K.: Yes, putting a Class 2 vapor retarder of any type on the inside wall would do the trick. You correctly point out that a membrane on the inner surface could be subject to damage. That’s why Joe says, “I’m a sheet goods guy.”

Lee: I wrote an article last year about a Passive House builder (Hammer & Hand) that made their best practices manual available to anyone who wanted it, and it contains good details for how to do that.

Dave: Yes,

Dave: Yes, Joe prefers continuous exterior insulation to double-stud walls. He did it on his own house, which you can read about it in this great article he wrote:

Leiningen versus The Ants Redux

.

Allison, I’m ever more

Allison, I’m ever more impressed by and appreciative of your ability to condense, translate and communicate complex concepts for us mere mortals in the building community. Yep, occasionally an error like this will be made, and I’m very impressed by the way you handled it expeditiously and professionally. With this blog post you earn even more respect and gain even more credibility from your peers. Well done.

As for the double-wall? Nice, but there are so much easier ways to solve both thermal and moisture problems. Anyone interested in learning about materials and techniques that work where it’s seriously cold should go the CCHRC website (Cold Climate Housing Research Center, CCHRC.org) Look at the project in Galena and the brilliant wall construction they used for affordable housing.

Keep up the great work, Allison. We look forward to every blog post.

Allison, what is holding the

Allison, what is holding the interior wall insulation from falling into the 4.5 inch air space?

Mac S.:

Mac S.: Thank you, sir! I have to make it simple enough so I can understand it. Here’s a direct link to the Galena page at the Cold Climate Housing Research Center:

Galena Prototype Home

Edgar: Unfortunately the BSC diagrams don’t show the bottom of the wall details, but there would need to be OSB or plywood at the bottom, connecting the outer double-stud section to the bottom of the structural wall, maybe using a ledger.

No mention that the moisture

No mention that the moisture meters may have been installed incorrectly and gave false readings. Just saying.

No mention that the moisture

No mention that the moisture meters may have been installed incorrectly and gave false readings. Just saying.

Seems to be some confusion in

Seems to be some confusion in the comments (and responses by AB). <br /> <br />First, I think Thomas D’s link did a good job explaining the not-often used term double-wall as a non-insulated wall where outer sheathing also serves as the inside wall — thus ‘single wall’. <br /> <br />OTOH, by that definition, a double wall is what we think of as conventional stud wall — with sheathing on outside and drywall (or whatever) on the inside, thus two surfaces or double wall. <br /> <br />That said, methinks building science terminology is confusing enough without imposing such a limited regional slant on everyone else. <br /> <br /> <br />As for Edgar’s question, I believe he’s asking why the insulation doesn’t fall in the gap between the two walls. If so, then the correct answer is that the insulation is supposed to fill the in-between gap (see 2nd diagram). <br /> <br />Finally, after reading the previously referenced article, I saw nothing to lead me to think Joe endorsed that wall. And after the postscript you added relating Joe’s phone call, no one else would have, either. <br /> <br />If Joe gave you a hard time for not spelling out a disclaimer on his behalf in your article, you should have told him to chill. I thought you did a fine job "reporting" on Kohta’s report.

Seems to be some confusion in

Seems to be some confusion in the comments (and responses by AB).

First, I think Thomas D’s link did a good job explaining the not-often used term double-wall as a non-insulated wall where outer sheathing also serves as the inside wall — thus ‘single wall’.

OTOH, by that definition, a double wall is what we think of as conventional stud wall — with sheathing on outside and drywall (or whatever) on the inside, thus two surfaces or double wall.

That said, methinks building science terminology is confusing enough without imposing such a limited regional slant on everyone else.

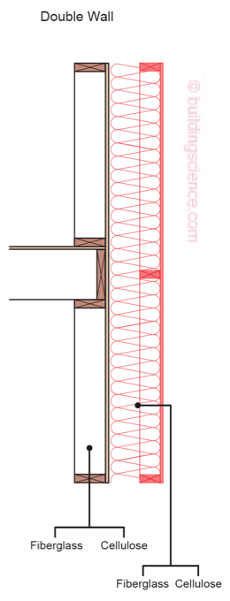

As for Edgar’s question, I believe he’s asking why the insulation doesn’t fall in the gap between the two walls. If so, then the correct answer is that the insulation is supposed to fill the in-between gap (see 2nd diagram).

Finally, after reading the previously referenced article, I saw nothing to lead me to think Joe endorsed that wall. And after the postscript you added relating Joe’s phone call, no one else would have, either.

If Joe gave you a hard time for not spelling out a disclaimer on his behalf in your article, you should have told him to chill. I thought you did a fine job “reporting” on Kohta’s report.

What’s the construction

What’s the construction sequence for the outer wall? <br /> <br />1. Frame from foundation to roof. <br />2. Install insulation <br />3. Hope it doesn’t get windy or rainy. <br />4. Install exterior sheathing & WPABL. <br />5. Install exterior finish. <br /> <br />Is that it?

What’s the construction

What’s the construction sequence for the outer wall?

1. Frame from foundation to roof.

2. Install insulation

3. Hope it doesn’t get windy or rainy.

4. Install exterior sheathing & WPABL.

5. Install exterior finish.

Is that it?

David, <br />

David, <br /> <br />Your questioning the construction sequence for the outer wall, is why I recommend a slightly different procedure. <br />1. Frame from foundation to roof. <br />2. Install exterior sheathing & DP <br />3. Exterior siding = weather tight shell. <br />4. Install insulation in exterior framed wall. <br />5. Continuous insulation board attached to interior of studs. <br />6. 6 mil vapor retarder next attached to floor decking and cap vapor retarder (bit more difficult on multistory). Significantly reduces air infiltration between and under all plates & studs. <br />7. Next build second lightly framed curtain wall (studs offset)to hold all electrical & any plumbing inside of continuous vapor retarder with more insulation then sheetrock+. <br /> <br />This system allows for easier framer understanding (no insulation blowing in the wind) and much easier quality control. <br /> <br />Like Dr. Joe’s there is much more to this system.

David,

David,

Your questioning the construction sequence for the outer wall, is why I recommend a slightly different procedure.

1. Frame from foundation to roof.

2. Install exterior sheathing & DP

3. Exterior siding = weather tight shell.

4. Install insulation in exterior framed wall.

5. Continuous insulation board attached to interior of studs.

6. 6 mil vapor retarder next attached to floor decking and cap vapor retarder (bit more difficult on multistory). Significantly reduces air infiltration between and under all plates & studs.

7. Next build second lightly framed curtain wall (studs offset)to hold all electrical & any plumbing inside of continuous vapor retarder with more insulation then sheetrock+.

This system allows for easier framer understanding (no insulation blowing in the wind) and much easier quality control.

Like Dr. Joe’s there is much more to this system.