Can Door Undercuts Work As Return Air Pathways?

Most people don’t know that simply closing a door in their home can make them sick, increase their energy bills, or reduce their comfort. We live in this invisible stuff called air. We pull many pounds of it into our lungs each day. A typical air conditioner, heat pump, or furnace easily moves 20 tons of air a day. (Yes, I’m talking about 40,000 pounds! We’ll save that calculation for another day, though.) And the simple act of closing a door changes the dynamics of a house in ways that can have profound impacts on the people inside the home.

Last week I wrote about the problem of bedroom doors getting closed, the consequences of that action, and one way to alleviate the problem. In that article I mentioned the issue of undercutting the bedroom doors as the standard method many homes used as a return air pathway. The air pumped into a bedroom needs to find its way back to the air conditioner, heat pump, or furnace. Door undercuts are one such return air pathway. But, I wrote:

Door undercuts typically won’t allow enough air to get out of the bedroom unless you leave a gap bigger than most people want under their doors.

The conventional wisdom on door undercuts

Ah, conventional wisdom. It’s often not wisdom at all and you may get different versions of it depending on which convention you believe. That’s certainly the case here. Talk to people in the HVAC industry and you’ll find quite a few who say you never need anything more than a door undercut. The one comment I’ve gotten so far on the video on bedroom pressures I made for my last article was, “Haha 7 pa is >0.03in wc soooo… Very little. It will sweep under the door.” He didn’t identify himself as such but since he thinks in inches of water column (iwc), I have a strong suspicion he’s an HVAC guy. (I also think the evidence points to the commenter being male but woman’s intuition doesn’t always get it right, even for someone in Who’s Who of American Women.)

That kind of conventional wisdom is why we have homes like my condo, which had a 7 Pascal (Pa) pressure difference before I installed the Tamarack return air pathway in the door. (Disclosure: Tamarack is an advertiser in the Energy Vanguard Blog.) Mike MacFarland of Energy Docs, a home performance contractor in northern California, says it can be even worse than that. He’s found many homes with bedrooms that get pressurized to over 40 Pa when the bedroom door is closed. Wow!

In contrast, the statement I threw out in that last article about the inadequacy of door undercuts represents the conventional wisdom of the building science community. Building Science Corporation has a page about door undercuts as return air pathways and says this:

This approach is acceptable but Building America research has demonstrated that the common technique of undercutting bedroom doors does not provide for enough airflow.

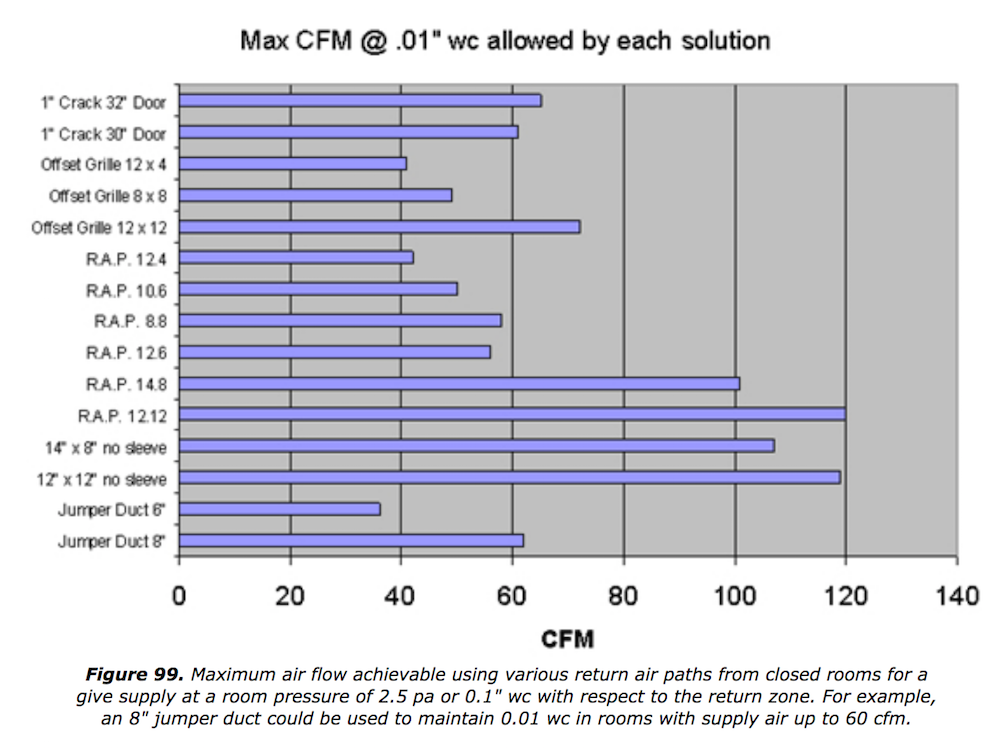

They don’t provide the reference to that Building America research but I think it’s probably a study done by the Florida Solar Energy Center (FSEC). Published online as the Return Air Pathway Study, their report shows the air flow through various types of return air pathways, including door undercuts. The chart below shows the results.

They found that a hole the size of a typical one inch door undercut will allow about 60 cubic feet per minute of air flow. In terms of air flow to size of the hole, door undercuts come out on top. They yield about 2 cfm per square inch of hole. (See Table 60 in their report.) But compared to the air flow many bedrooms need, 60 cfm is on the low side. And that’s with a one inch undercut. With a half inch undercut, the number will be reduced greatly. (Unfortunately, they didn’t include half inch undercuts in their study.)

The wisdom of data from real houses

Building Science Corporation and FSEC are right in calling out door undercuts. As I mentioned above, many in the HVAC industry believe wholeheartedly in door undercuts. In many homes they don’t work. Look at the article I wrote last week about what happens in my condo without the Tamarack return air pathways I installed in the doors.

But we also need to understand the bounds of this new understanding about door undercuts. And it’s helpful to know what that FSEC study did not show. Maybe door undercuts work just fine for some houses.

That’s what John Semmelhack of Think Little has found. He commented in my last article, writing “We design and balance systems all the time with central returns and WITHOUT transfer grilles or jumper ducts for most bedrooms.” He finds that a half inch door undercut works just fine in most of the homes he tests.

So, are we back to saying the HVAC folks are right? No, not really. Semmelhack works on high-performance homes. He certifies homes for ENERGY STAR and Passive House and also does some net zero energy homes and deep energy retrofits. That’s the first thing the building science conventional wisdom doesn’t include. When a house is really efficient, the bedrooms won’t need as much supply air delivered.

The other thing neglected by the building science conventional wisdom is the other air flow. When you close a bedroom door, the undercut isn’t the only pathway for return air. Walk over to a bedroom (or other interior) door and close it. Look at the gaps on the sides and top. Grab the handle and see how much movement there is.

The door undercut gets all the attention, but the sides and top of the door also allow a good amount of air to flow through. Semmelhack believes the air flow through the sides and top of the door is equal to the air flow through the undercut. So if you can get 60 cfm under the door, you can get about 120 cfm total.

And that’s what the FSEC study seems to have missed. They don’t discuss it in their report but it appears from the photos that their only pathway for air flow was the hole they cut. They built a little test hut out of foam board, which I imagine was airtight except for the holes being tested. They didn’t discuss the airtightness of the hut in their report.

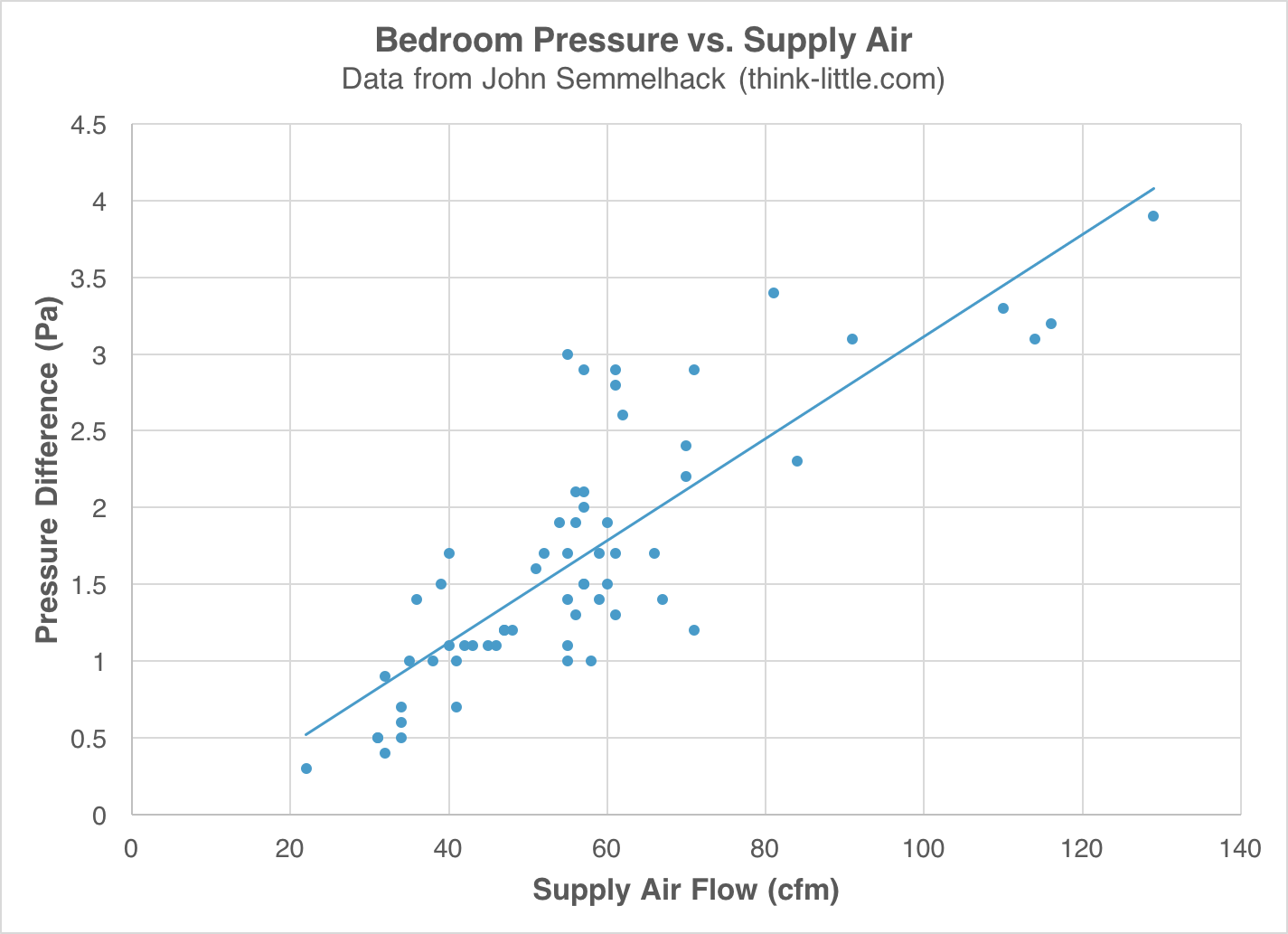

Semmelhack is one of the people in our industry who goes out and tests things to make sure they work. It’s required, of course, for ENERGY STAR and Passive House, but he goes further than is required. The graph below shows his data for the pressure difference in bedrooms as a function of the conditioned air supplied to the bedroom.

It’s not a tremendous amount of data but it’s enough to see that door undercuts work. For supply air up to about 80 cfm, the pressure stays below the ENERGY STAR required threshold of 3 Pascals (Pa). All of the bedrooms being tested here have only half inch door undercuts as return air pathways. No return vents, jumper ducts, or transfer grilles. And the vast majority meet the ENERGY STAR requirement of <3 Pa pressure difference between the bedroom and the hall. Only two times has he had a problem getting bedrooms under the 3 Pa threshold with 75 cfm of supply air. In both cases, the door was installed really tightly.

The new building science conventional wisdom

As is so often the case, the truth is found between the extremes. Door undercuts are neither always adequate nor always inadequate. Sometimes they work. Sometimes they don’t. With low-load homes, the lower air flow required in bedrooms means half inch door undercuts — along with the flow around the sides and top of the door — might well be sufficient. The more air required for a bedroom, the more likely it is you’ll need to put in an additional return air pathway.

Of course, it’s pretty easy to get this right. All we need is proper commissioning. If every home were tested for bedroom pressure differences and held to a maximum 3 Pa, we wouldn’t need to have this discussion.

Related Articles

An Easy Retrofit for Return Air From Bedrooms

The 3 Rules of Air Leakage (Plus a Bonus!)

The Sucking and the Blowing — A Lesson in Duct Leakage

MAD AIR: Duct Systems, Infiltration, & Their Interactions

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 34 Comments

Comments are closed.

Lowly carpenter here, not

Lowly carpenter here, not really excited about aesthetics of door grills, how about returns installed in ceilings accessible via attic?

John, yes, you certainly can

John, yes, you certainly can install return air pathways in a ceiling or in a wall. But first check out the air flow delivered to the room and see if maybe the door undercut will suffice.

Father installed individual

Father installed individual room [except bath]supply and return metal ducks in 150 years old 2 story farmhouse, no central return [ballon framing] along with electrical in 1940.Can I assume this was overkill?

The firm I worked for did return bath air using charcoal filters, over my objection, in the Forestal building, were they ever replenished?

HM, my guess is that it may

HM, my guess is that it may have been overkill in that old a house but I’d need to know more about the house. I think it was certainly unusual for that era, though.

Why a 3 Pa limit? Is that the

Why a 3 Pa limit? Is that the threshold for energy efficiency, comfort, and/ or durability? I’m curious what the science is behind that figure. The only real science I’ve seen about the effects of Zonal Pressure Difference are in John Tooley’s MADD Air article, now about 30 years old and mostly involving pressure differences in the 25 Pa range.

As an ENERGY STAR verifier, I’ve asked the provider how strict that measure is in the program. The answer I got? “As long as it’s under 7 Pa or so, should be fine.”

Again, where’s the science? At what point are you causing issues? Commercial buildings that need clean indoor air, like labs and hospitals, are routinely designed to operate at 12.5 Pa continuously.

Does that make these building types energy hogs?

Waylon, that’s a great

Waylon, that’s a great question. My guess is that the 3 Pa is actually rounded up from 2.5 Pa. (And the 2.5 Pa is rounded up from 2.48 Pa.) 2.5 Pa is equivalent to 0.01 inches of water column, a nice round number. It’s also the number they chose for the bedroom pressurization limit in the Florida mechanical code way back in 2003. I don’t know the history here but my guess is there was never any science behind that number. It was just a number that was significantly lower than many bedrooms were attaining.

If your provider is really saying that 7 Pa is fine for ENERGY STAR homes, they’re violating the requirements of the program.

Thanks for the back story.

Thanks for the back story. FYI, the response I got regarding ENERGY STAR certification said the 3 Pa limit is not a hard line in the sand, since it has minimal impact on the home. It falls in the “rater discretion” category, and exceeding the limit is acceptable as long as it’s not egregious and prescriptive pressure relief is installed – while a recommendation should be made to the builder to remediate the design for pursuant homes. When pushed to clarify “egregious”, they said it’s 7 Pa or so.

My hunch is the effect on home efficiency and comfort is larger in hot-humid climates where moisture load is a major factor, hence the Florida building code. I wonder, how many code inspectors down there carry a manometer?

We’ve wondered the same…so

We’ve wondered the same…so we occasionally test it. I encourage you to do so as well! Here’s our data:

(airflow with door open / room press. with all bedroom doors closed / airflow with doors closed)

68cfm / 2.6Pa / 65cfm

67cfm / 2.1Pa / 65cfm

129cfm / 3.9Pa / 123cfm

55cfm / 3.0Pa / 54cfm

57cfm / 2.9Pa / 55cfm

Based on this limited data, we think we can expect a negligible drop in supply airflow (less than 5%) and negligible impact on air leakage across the enclosure when room pressure is limited to ~3Pa.

It’s disheartening to hear the information your Provider gave to you. The Energy Star standard is 3Pa. Period. Not 7, not 5, not 4…it’s 3. Is the threshold arbitrary? Somewhat…but as we move over 3Pa, we move into the territory where the impact is no longer negligible. The line has to be drawn somewhere.

Regarding labs and hospitals – yes, they are energy hogs compared to most other building types. The strong room / building pressurization is part of the reason.

Oh, by the way, last year I

Oh, by the way, last year I wrote about the MAD Air article by Tooley and Moyer. I’ve added the link to the list of related articles above, or you can click the link in the first sentence of this comment.

This is eye opening. I had

This is eye opening. I had read the info from Tamarack, Lstiburek and others, but did not connect the dots how high performance homes affect this matter. Thank you for pointing this out.

You’re welcome, Mark. A lot

You’re welcome, Mark. A lot of things are different with high-performance homes.

It’s also another argument

It’s also another argument for right-sizing equipment. Excessively large equipment requires larger return air pathways…

Hi Allison. Do you know of

Hi Allison. Do you know of any studies that add ventilation supply air (10-20cfm/bedroom for homes with dedicated ERVs) to the forced air cfm to see if the sum of undercut plus leakage around sides and top of door is sufficient?

John, no, I don’t know of

John, no, I don’t know of such a study, but John Semmelhack’s results would still apply. He didn’t tell me but I’m sure at least some of those bedrooms included ventilation air, which should be reflected in the supply air number in his graph.

Yes – a few of those include

Yes – a few of those include independent supply ventilation air…the results still apply. The effect is obviously additive if you have heating/cooling supply air as well as ventilation supply air. The opposite would be the case for rooms (such as bedroom suites) that have continuous exhaust ventilation. When we have master suites with continuous exhaust from the bathroom, we always look at the net design airflow when deciding whether or not to include a transfer grille in the plan.

We’re thinking about this all

We’re thinking about this all wrong. This should be a trigger for better building envelopes. Stay with me here…

“…but the bedrooms need more than 60 cfm of air flow”

“Ooooo… Then you’re going to have to install these huge vomit green transfer grills at the bottom of each door.”

“Really?!”

“Or you could increase Insulation levels and air tightness, then size equipment accordingly.”

“How about we do that.”

“Good choice.”

See how that works.

It’s always been my

It’s always been my understanding that a bedroom with a closed door that is positively pressurized due to insufficient return is pushing air out not only at the door undercut and jamb stops, but also through any break in the pressure boundaries that seal the room from outdoors. Therefore if the room with door closed can be made as neutrally pressurized (as measured across the closed door) as possible does that then reduce the amount of conditioned air leaking to the outdoors? I think so, and perhaps the number discussed above re: 3 pascals or less is related to this reasoning.

I trained my guys to find a

I trained my guys to find a wall cavity that is connected to hallway return air path. put a low wall grill on both sides of that wall. make one high and the other low. 2- 6×8 grills will take care of the pathway. Install the high side wall grill on the exterior wall of the bedroom to take noisy children away. Keep the electrical wire out of the space. and not leaks in the top and bottom plate framing. cost about $5.00 and your dont have to tear up a cheap or expense door.

I specify ductless or central

I specify ductless or central returns for all of my projects, so I make a point to ensure there’s a low-static (less than 3 PA) return path from every room.

I use the 2 CFM per square inch rule-of-thumb for door undercuts, up to 3/4″. If an undercut is sufficient based on a room’s design airflow, then I call out the minimum undercut on my spec. Otherwise, I specify a jump duct or transfer grille. For walk-in closets without an actionable load, I specify a louvered door. All of this is in consultation with the homeowner and/or builder.

BTW, regarding John’s observation regarding leakage around doors, I agree and have seen this in the field, especially with pocket doors. But from a design standpoint, the 2 CFM per sq.in. of undercut rule keeps me out of trouble 🙂

All joking aside, I think one

All joking aside, I think one of the problems with depending on undercuts is that they are not generally recognized as a return pathway. If someone decides to add fluffy carpet where there a laminate floor in the future is can effectively block this pathway and they wouldn’t even realize what they’ve done. Other methods look like something with a purpose.

Andrew,

Andrew,

Of course, occupants don’t always recognize the purpose — or at least the function and needs — of return grilles placed in the floor or walls. Sometimes they seem to think the purpose of vents is to be covered with various objects. I’ve seen furniture, rugs, and dog beds right on top of floor vents and furniture and other objects pushed right up against sidewall vents. No method is immune from the actions of occupants who don’t know how all this works.

Having lived in Europe, I

Having lived in Europe, I used to assume the purpose of door undercuts was childproofing-related:

1. Large enough to slide the room key underneath, because bedroom doors used to have individual keys

2. Large enough to pass a sandwich to my child who locked himself in, while waiting for alternative ways to get the door unlocked

As a carpenter I have been

As a carpenter I have been advocating larger undercut for years. Client always resist 1″ gap over the floor covering. I like the suggestions for wall, ceiling jump ducts, etc. I have a problem with the door vents you are passively promoting. Using the link you have provided it has a picture of a french full lite door with a vent that has removed a significant part of the door’s base. So much of the base frame has been removed that the door will fail in holding itself together over time and will start to sag. Look at any old neglected weathered exterior wood door or fence gate for that. Why do you think the base frame is wider than the side or top stiles? That where the strength is. That picture illustrates what never to do. Never compromise the the structural frame of a door! look at 1″+ floor gaps or wall, ceiling and jump ducts as a better solution.

One point to consider, while

One point to consider, while various methods may work, relying on undercuts and door slack alone provides very dusty jamb interiors down the road

The floor covering makes a

The floor covering makes a huge difference in how much air a door undercut can move. Bruce Manclark and I of Delta-T once did some mockup testing of zonal pressure relief (ZPR) options that included a standard pre-hung interior door. A 1″ door undercut on smooth flooring does move ~140 cfm@ +3Pa, as the testing showed, but only ~60 cfm over carpet, and compared to ~70 cfm for a 3/8″ door undercut over smooth flooring. (Note to Allison: I can email that PowerPoint to you if you are interested.)

QA testing in ~7 ACH50 Oregon Energy Star spec homes with nominal 1″ interior door undercuts usually showed bedroom pressures in the +2 Pa to +8 Pa range, with occasional +15-20 Pa outliers. It was not unusual to find master bedrooms with forced air returns at more than +3 Pa. The main body of the house is then usually negative wrt outside by -3 Pa to-10 Pa, with occasional outliers more than -20 Pa. Contractors and homeowners complained bitterly about having to undercut the doors so far and sometimes fudged the dimension.

High positive pressures in peripheral rooms generally result in higher negative pressures closer to the return(s), even in leaky houses. Seems like we all agree neither of these is a good thing.

It was not that unusual to find atmospheric draft water heaters installed in conditioned space that was at -3 Pa to -8Pa, which is enough to backdraft the appliance, right? Which may have something to do with the magic -3 Pa number. Putting these crappy water heaters in the garage is no panacea, since attached garages with forced air furnaces in them are typically -2 Pa to -10 Pa wrt outside and the house, more if the filter door isn’t installed properly (but that would never happen, right?)

A big problem with door undercuts is allowing occupants and interior decorators to so easily re-engineer the heating and ventilation systems with rugs, towels, and clothes. QA testing in occupied homes shows it not unusual to see defeated door undercuts in homes with children or lots of occupants. How many HVAC contractors or inspectors check zonal pressures in finished homes and learn to correct the problems? They are the cheapest option, but I don’t think door undercuts are a reliable solution to zonal pressure relief.

In airtight homes with small heating loads, any heating supply airflows may be minimized, but ventilation airflows become more critical. We want to supply the master bedroom at least 30 cfm. Conventional fully-ducted HRV/ERV ventilation systems usually make bathroom exhaust air registers the main collector for the entire volume, often resulting in 60-80 cfm flows into each bathroom. Then good bathroom ZPR becomes even more critical than the bedrooms. Do we really want a bathroom rug to re-design our heat recovery ventilation system in an airtight house? American flex duct and missing bath ZPR have already pretty well defeated the airflows in nearly all of the heat recovery systems I have QA’d.

Thank You so much Allison for

Thank You so much Allison for this very important issue, living in Florida i deal with the hvac installers all the time on this undercut door subject, i typically tell the industry that about 30 cfm’s at best will exit trough the undercut when the door is closed (beds need on average 100 cfm)- many believe they are forced by the codes to add transfers (i hate transfers) or ducted return – they have little clue of the actual .001 engineering requirement. could we also now get a discussion about the manual T / D location for the return air pick up . see my link to paper about cooling dominant return air locations – transferring the warm moist column of air from a high wall transfer into an adjacent hall way is not the best solution (but at least we have the industry tuned to balanced return air) for a cooling dominant region as this transfer air is usually expected to be returned to a low wall return air grille in our region! pushing this air to an adjacent room is a poor choice. as most new homes require a ventilation air duct, there is also no way to balance the free draw low wall return and ventilation air duct because there is no plenum to place the volume control dampers – the path of least resistance wins every time, so no ventilation air is induced while using an open stand with a single low wall r/a……passes code official inspection every time…so our installers believe that if it passes inspection it must be engineered correctly! help Florida please, your highly respected by professional designers in our region despite FSEC missing that critical point on this subject —>white paper http://www.hvacdesigns.com/wp-content/uploads/2018/01/Ceiling-Return-Air-Grilles-for-Cooling-Dominant.pdf?bb83b9&bb83b9

As always, a great article.

As always, a great article. What I found missing was any reference to what constitutes a “bedroom”? Don’t we need to take into account the number of vents and flow into the space? I had a problem experience with a home I built that the master bedroom was actually a master suite, consisting of a large sitting area, large walk-in closet, enclosed toilet space, and a long vanity with two sinks in addition to the area large enough for a king sized bed. There were six vents supplying this area. Their door would slam shut during the night. We had to find space for a large grill to vent into the hall. Not pretty but worked. We should have designed return vents in the ceiling or better yet, its own return duct. Lesson learned.

Thomas wrote: “What I found

Thomas wrote: “What I found missing was any reference to what constitutes a “bedroom”? Don’t we need to take into account the number of vents and flow into the space?”

It’s not the number of vents or the type of room but the design airflow for the room that determines the design return airflow. Also, it matters not if there’s a dedicated return duct, or a passive return path to a central return as long as the return path isn’t restrictive to the point that it impacts overall supply air balance.

Could you calculate the

Could you calculate the return path vent size needed under the door by knowing the size of the vent in the room?

@Richard, I’ve seen

@Richard, I’ve seen guidelines (aka rules of thumb) for how much airflow a given size diffuser can or should have, but the reality is all over the map. So I don’t recommend trying to size door undercutor transfer ductgrillebased on supply vent dimensions.

In general, return paths should be sized based on room-by-room design airflow and field verified via zonal pressure testing. Anyone who operates a blower door or duct tester will have a digital manometer that can measure pressure differentials in the appropriate (i.e., minuscule) range. It only takes a few minutes. However, when testing indicates a problem, calculating the minimum return path to get to 3 Pascals requires an accurate flow hood to measure the actual supply airflow, which unfortunately is less common in the trade. Anyone who routinely does zonal pressure diagnostics should own a good flow hood, although I suspect trial-and-error is the status quo.

I dry walled right over all

I dry walled right over all of the vents above the doors of the bedrooms in this new house. They completely defeat the primary function of a room which is to block light and noise from entering. What purpose is there to having a room at all if there’s a giant vent letting all sound right through it?! May as well just not have doors. It’s the dumbest thing I’ve ever seen and there hasn’t been a single problem with the vents gone. The doors don’t slam, the rooms don’t feel any different than before, there’s no issues. If you’re designing a new house and you want to nerd it up over pressure differentials that nobody else cares about, at least do it the right way and use jump ducts or some manner of preventing sound from traveling room to room. Short of that we’d all need our own houses on the same block to live with anyone else. So idiotic.

Jonathon,

Jonathon,

You offer not solution other than all other replies which do as idiotic? You state the reason for having a room is to block out light and noise. I agree to this on a technical level, however, I would suggest the primary reason is comfort. Those irritant you refer to are little league matters. Noise and light are easily over come. A 8X8 grill or hallway noise sneaking into or out off are superficial at best. But, If a person is to Hot or to Cold due to their human comfort then you have a permanent because someone is blocking the path of correct airflow.

What un-expensive tool can be

What un-expensive tool can be used to be able to measure pressures between rooms?

I’ve got a bedroom door that

I’ve got a bedroom door that closes itself when the air is running and it’s already less than a foot agape. I’ve got another door that slams shut (obviously none that swing open). Not owning a manometer, how does this correlate to 3Pa vs 7Pa difference ?