HVAC Design Done Right – Manual J, S, T, & D

My grandfather (yes, the first of this line of 3 Allisons!) was an electrician, plumber, and HVAC contractor, and I had the great fortune of being able to spend a month or two every summer from the time I was about 12 working with him and my uncle Dickie. I’d go out on calls with them all day long, where we’d run wire in a new car dealership, snake out a drain, or replace the freon in an air conditioner. (Don’t ask what we did with the old freon; this was the ’70s, you know.)

My grandfather (yes, the first of this line of 3 Allisons!) was an electrician, plumber, and HVAC contractor, and I had the great fortune of being able to spend a month or two every summer from the time I was about 12 working with him and my uncle Dickie. I’d go out on calls with them all day long, where we’d run wire in a new car dealership, snake out a drain, or replace the freon in an air conditioner. (Don’t ask what we did with the old freon; this was the ’70s, you know.)

My grandfather (yes, the first of this line of 3 Allisons!) was an electrician, plumber, and HVAC contractor, and I had the great fortune of being able to spend a month or two every summer from the time I was about 12 working with him and my uncle Dickie. I’d go out on calls with them all day long, where we’d run wire in a new car dealership, snake out a drain, or replace the freon in an air conditioner. (Don’t ask what we did with the old freon; this was the ’70s, you know.)

My real education about heating, ventilating, and air conditioning (HVAC) systems has come over the past decade, however, as I’ve spent a lot of time inspecting and testing duct systems, determining equipment efficiency, and learning the intricacies of Manual J heating & cooling load calculations. One of the biggest lessons I’ve learned is that HVAC design is a lot more than Manual J.

Most HVAC contractors, home energy raters, and others in this field know about Manual J. Many people even know about Manual D, which describes how to design the duct system. Not so many, however, know about the missing links – Manual S and Manual T. If you want a properly designed HVAC system, you have to go through the whole process in all four protocols: J, S, T, and D. (It’s easy to remember the order. As a friend of mine says, first J, then STD.)

Here then is a brief description of each manual.

Manual J

This one is for determining how much heat the house loses in winter and gains in summer. You do this room-by-room for the whole house, which allows you to determine how much conditioned air each room needs for both heating and cooling. It factors in all the surfaces of the building envelope, with their areas and insulation levels. Each wall is given its proper orientation, because windows and doors are attached to them. Other important data include the location and tightness of the duct system, the infiltration rate of the house, the internal loads (appliances and people), and where the house is located.

The results specify the BTUs of heat lost by each room in the winter and gained in the summer. The heat gain is split into two parts: Sensible (related to temperature) and latent (related to humidity). The heat gained or lost in a room then determines how much conditioned air that room needs, in cubic feet per minute (cfm).

Manual S

Once you know the amount of conditioned air necessary in each room, you have to select the equipment. What air conditioner, heat pump, furnace, or boiler are you going to install? With forced air systems, this part is critical because every piece of equipment has different characteristics – sensible and latent capacities, the amount of air moved, and the static pressures being the key ones for the next stages.

Manual T

From the room-by-room loads and cfm requirements, you can determine how to distribute the air in the room so that you get enough to meet the needs (the higher of the heating and cooling cfm requirements from Manual J). The questions you answer here are: Where will the supply registers, diffusers, or grills be located? Where will the return grills be located? What type of register, diffuser, or grill will you use? How big does it need to be?

Good choices here will eliminate problems of feeling drafts from the moving air or having inadequate mixing of the air. It’s possible to get enough conditioned air into a room but still have it uncomfortable because all the air just sits at the register.

Manual D

Finally, once you know how many cubic feet per minute of conditioned air you need for each room, what equipment you’re using, and how you’re distributing the air in the room, you can design the duct system. Here you look at the location of the air handler, the distance to the ducts, how many turns the ducts have to make, and how much air needs to be delivered. The type of duct has a big impact on the results, as sheet metal ducts have a lower friction rate than flex duct or rigid fiberglass duct board.

Basically, with Manual D, you’re trying to balance the delivery of the correct amount of air against the friction rate of the ducts and the static pressures in the system.

Pulling It All Together

When you get all four manuals done and have a well designed HVAC system, the result can be a high performance system that’s more efficient and comfortable than what’s typically installed. Of course, you can have the best HVAC design in the world, but if it’s not installed as designed, your performance goes out the window. That’s why it’s a good idea to have every new system fully commissioned – and that’s the topic for a future article!

Building or remodeling a house and need help with the HVAC and duct system design? We do that.

This Post Has 2 Comments

Comments are closed.

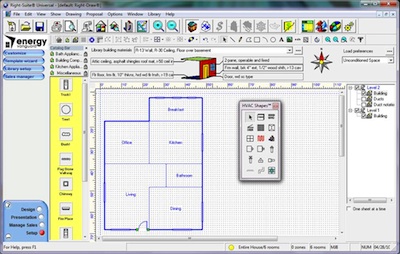

What program are you using in

What program are you using in the screenshot? Seems interesting, might be something that my students will like to learn.

please send me books and

please send me books and other advices