Grading an Attempt to Get Ducts Inside Conditioned Space

There’s a ton of new construction and remodeling going on in Atlanta. On a lot near where I live, a developer tore down the old house and is building two new ones. This weekend, I took the opportunity to check out their progress on the first one and saw the mechanical system roughed in on the first floor. They did some good things in their attempt to keep the air handler and ducts inside conditioned space. They also did some not-so-good things. Let’s grade their work.

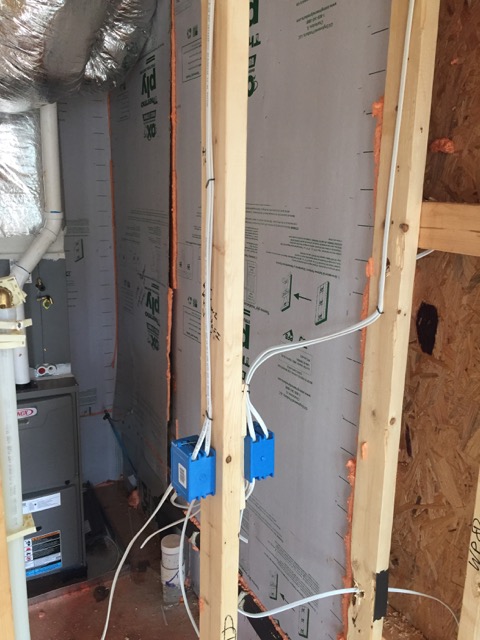

Mechanical closet

Exterior walls – Grade: A-

As you can see in the lead photo above, they insulated the walls and covered them with a layer of interior sheathing before they installed the equipment. They also sealed the edges with spray foam. I gave them an A- instead of an A because there’s one place where the T-Ply is coming apart. I assume they’ll fix that.

Furnace – Grade: A

They used a high efficiency, sealed combustion furnace. For combustion equipment inside conditioned space, that’s definitely the way to go. You can tell it’s a high efficiency, sealed combustion model because of the plastic flue pipe in the photo above. And yes, they installed both pipes, intake and exhaust.

Placement – Grade: C

The mechanical closet is in the back of the house. While it’s nice to have it out of the way and leave the middle of the house for espresso makers and powder rooms, the result was long duct runs to the front of the house. Worse, the two vents on the left side of the house had to go around the stairs (see 2nd to last photo below). From the air handler to those vents, the air has to make its way through ten 90° turns and four 45° turns. Finding a way to get the air handler into the middle of the space would have avoided long runs.

Duct System

Installation quality of ducts leaving air handler – Grade: F

The duct system here is radial rather than trunk and branch. It’s all flex duct. Because of the constraints, the flex doesn’t meet the Air Diffusion Council’s standards for flex duct installation. Notice the mess of ducts coming up out of the mechanical closet. Notice the turns and the squishing. With a trunk and branch duct system, they would have installed only a few ducts, ideally hardpipe rather than flex, coming up out of the closet.

Keeping the ducts inside conditioned space – Grade: C

Oops! It looks like that attic above the mechanical closet is meant to be insulated at the drywall ceiling, not the roofline. That means those ducts will travel a bit through unconditioned attic space. A couple of the ducts also go out into the attic over the porch, as you can see below. Also, because of all the ducts in that little attic space, they’re going to have a heck of a time insulating it properly.

Straight runs – Grade: A

Where they could, the installers ran the flex duct to the vents in nice, straight runs. It looks like they pulled it tight, too. Although it’s the inner liner that needs to be pulled tight, if they got the outer liner pulled tight, it’s likely the inner liner is fairly tight. (See second photo above.)

Turning the air – Grade: D

They’re not the worst turns I’ve seen, but they did make every turn in the flex duct using the flex itself. That adds much more resistance than installing rigid metal elbows to turn the air. And there are a lot of turns, especially in the duct that has to go around the stairs (above).

Butt joints – Grade: C

Flex duct comes in 25′ lengths. When you run 50′ of flex, you’ve got to connect pieces together. They did use rigid metal connectors at the two joints I checked out. But I can’t give them higher than a C here because if they had used metal elbows at the turns, they wouldn’t have needed any butt joints in the straight sections. Even better, if they had gone with a trunk and branch system, they wouldn’t have needed any butt joints.

The best way to get ducts inside conditioned space

So, in this home they got the air handler in conditioned space. They got the ducts mostly in conditioned space. And they had to make a lot of compromises. I don’t blame the HVAC contractor here. No, the real problems in this home go back to the design phase. The architect who drew that mechanical closet should also have considered how the ducts would get to the different rooms on the first floor.

If you’re going to put an air handler and ducts inside conditioned space for a first floor system like this, here are a few tips:

- During the design phase, bring in the HVAC designer and contractor.

- Also bring in someone who can spot weak points in the building enclosure so everything gets insulated and air-sealed properly.

- Try to locate the mechanical closet centrally to eliminate long duct runs.

- Consider open-web floor trusses with spaces designed for trunk lines.

- Use flex duct only for straight runs.

- Consider using a central return. If the system is sized and designed properly, it doesn’t have to be noisy.

With a first floor system inside conditioned space, it’s important to get it right upfront. This isn’t like a system in an attic or crawl space. The ducts will be buried behind drywall when the house is finished. Good, integrated design is the way to go.

Need help with your HVAC design? We do that.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He is also writing a book on building science. You can follow him on Twitter at @EnergyVanguard.

Related Articles

How to Install Flex Duct Properly

The 2 Primary Causes of Reduced Air Flow in Ducts

3 Reasons Your 3 Ton Air Conditioner Isn’t Really 3 Tons

NOTE: Comments are closed.

This Post Has 25 Comments

Comments are closed.

Why do you think they put the

Why do you think they put the Thermoply sheathing on the inside as opposed to the exterior? We generally follow the rule that insulation should be as far to the exterior of the envelope as possible. Perhaps due to Atlanta climate?

The multiple large holes in the TJI’s make me nervous – anyone else? From the mfgr specifications: “For simple span (5′ minimum), uniformly loaded joists used in residential applications, one maximum size round hole may be located at the center of the joist span provided that no other holes occur in the joist.”

Large holes scare me too.

Large holes scare me too.

That was my first thought too

That was my first thought too–you can’t just cut holes in engineered joists like that!! How distracting. I see duct-size holes with just wires running through them too in one picture–not some kind of innovative new pre-cut floor joist product or something, is it?

But, not to distract from the point of the article, thanks for the perspective Allison, I oversee a lot of our HVAC contractors’ work when I put my “builder” hat on and there are definitely compromises that get made, that I try to address way back when I can put my “designer” hat on and it’s good to get a feel for how normal and how good or bad different compromises are.

In Atlanta, is anybody not using a lot of flex duct?

The hole through the TJI or

The hole through the TJI or BCI is larger than the max for a 9-1/2 or 11-7/8 inch joist plus only one hole is allowed by the TJI span tables. I would give them an F and a repair order on those joists that especially have 2 large holes as loading has been compromised.

Charles, the exterior already

Charles, the exterior already has sheathing (OSB). The reason I called it out is because a lot of times builders leave off the interior sheathing. Behind bathtubs on exterior walls is a common one. The insulation fills the cavity since this house is built with 2x4s.

Those holes, as scary as they look, may actually be OK. You’ve got to check the specs for the actual product you’re using, of course, but the TJI specs do indicate you can have holes that big in those locations. Even two sets, as you see in the case of the fourth photo above, are OK as long as they’re two diameters or more apart and meet the requirements for minimum distances to end supports. See page 9 of this document (pdf) for the TJI requirements: http://www.woodbywy.com/document/tj-4000.

Is there any cookie cutter

Is there any cookie cutter house plans that have an A grade in Hvac placement…unit and ducting?

There ought be a better way to grade energy efficient Hvac. Like measuring the cfm of vents, Hvac unit rating, and design of ducting with deductions for issues cited by Allison.

Leigha, see my reply to

Leigha, see my reply to Charles about the holes. Regarding flex, about the only time you’ll see hardpipe around here is on custom homes.

John, I understand the

John, I understand the feeling. Depending on which product they used, these holes may be OK, though. See my reply to Charles.

John, I’m not an expert on

John, I’m not an expert on allowable holes in I-joists. You may well be right. The document that I provided the link for in my reply to Charles, however, does seem to indicate you can have holes up to 8-7/8″ in an 11-7/8″ TJI. They also show a diagram indicating that multiple holes can be cut into one as long as the spacing is OK.

Having said that, TJI is the premium brand in I-joists. And even within that brand, you have a choice of several products. You may be right. Since I don’t know, though, I’m not going to grade that part of the installation.

Great question, Eric. I know

Great question, Eric. I know there are architects out there who do understand this, and some sell stock plans. I can’t think of who they are right now. Maybe another commenter will tell us of any they know of.

My guess about that second

My guess about that second set of large holes with only a few wires running through them is that they were a mistake. Someone cut the holes and the realized they couldn’t actually run the duct through them, or decided not to. Definitely not “some kind of innovative new pre-cut floor joist product.”

I shudder when I hear

I shudder when I hear ‘central return’ although they are popular and widespread in the market. They are probably the main reason air distribution systems don’t work as well as they should but they are cheaper than dedicated returns (it’s all about the money). I do think they’re fine as long there is a qualification that goes along with them and I’m sure you and most of those who read your blog would agree: For every cubic foot of air delivered to a space there must be a low velocity, low resistance, efficient path back to the air handler. There must be an adequately sized return associated with every supply (including closets, bathrooms and kitchens, etc.) Undercutting doors seldom meets these requirements and many central returns are undersized for a reasonable face velocity (or are attached to an inadequate duct). I’m just saying this for the benefit of those who may not understand how an air distribution system works. After all, you can’t ‘see’ air and how it struggles sometimes!

I’m perpetually amazed that

I’m perpetually amazed that architects manage to command the fees they do while also concocting “unductable” house designs.

For that matter, how is it that architects skate by without MEPs (Mechanical Electrical and Plumbing) plans?

Minor detail – whenever panduit straps (big white nylon zip ties pictured above) are used on the outer liner of flex duct, the fiberglass insulation directly beneath them is almost certainly compressed to a point where its R-Value drops from rated (typically R6 or R8) to “R-diddly-squat” (RDS)

RDS duct insulation, especially in unconditioned spaces, is vulnerable to surface condensation leading to wet spots, ceiling stains and other embarrassing and costly havoc soon after occupancy.

To avoid this, use panduit straps only on inner liner and ensure every square inch of ductwork is beneath continuous uncompressed insulation.

Good points, Robert.

Good points, Robert. Surprisingly, I’ve mentioned the issue of return air pathways many times in articles but still haven’t written an article dedicated to that topic. It’s time to do it.

Curt, there’s the “pen test”

Curt, there’s the “pen test” for determining the continuity of the control layers. Perhaps we need to start promoting the “ductability test” for architects.

You stated, “The duct system

You stated, “The duct system here is radial rather than trunk and branch”. That statement by itself I believe is incorrect if you are stating trunk and branch is superior to radial. If the air handler were in the center on the house and it was a true radial (like the spokes of a wheel) with straight smooth runs, it would be better than a trunk and branch. I agree that this system in this house should be a trunk and branch but a proper radial duct layout (seldom seen) I believe is superior.

Bob, if indeed I were stating

Bob, if indeed I were stating that trunk and branch is superior to radial, you would be correct that I would have been incorrect. But I wasn’t stating that. Radial can work fine if designed and installed properly. There’s nothing that makes one inherently better than the other.

But then, in theory, theory and practice are the same. In practice, they aren’t. I’ve seen more bad radial systems than trunk and branch systems.

Robert wrote: “(central

Robert wrote: “(central returns) are probably the main reason air distribution systems don’t work as well as they should”

I strongly disagree. The main reason air distribution systems don’t work is because of poor duct design and installation practice. A central return is never evidence of poor design. The real problem (to your point) is under-sizing central returns and not providing low resistance return paths. In low load homes, door undercuts can often handle smaller rooms but jump ducts and/or transfer grilles are always an option.

The rationale for having a single return location isn’t just a matter of money. A single return offers superior performance to branch or radial return topology. A ductless return, where possible, is even better. Here’s why:

a) Yes, a single return costs less, which ain’t nothing!

b) A single return (especially ductless) causes a lot less interference when trying to route ducts through floor trusses and soffits. Let’s not make it even more difficult to move ducts inside conditioned space!

c) A single return materially reduces blower energy, all else being equal.

d) In a basement, a ductless return that serves the floor(s) above ensures good air mixing and keeps basement humidity under control when there’s little or no sensible load in the basement. Isolating a finished basement from the rest of the house is one of the dumbest things we can do.

Another great article,

Another great article, Allison.

+1

+1

I give an F also for framing

I give an F also for framing & while it might have been “engineered” to allow for it (giving the benefit of the doubt), they should have only done 1 large hole for the duct per the guidelines — http://www.woodbywy.com/document/tj-9001 & then used a smaller hole to run the wires

As for single return versus one for every room – plusses & minuses for both as pointed out by David but especially when it comes to code testing. With that best is multiple though you can use a single if you design stuff properly

Question to Allison or anyone

Question to Allison or anyone else.

I’ve noticed in my area (Atlanta) new townhomes are equipped with dedicated range hoods instead of the obligatory POS recirculating/microwave bundle.

My question revolves around the exhaust ducting. Since I’m talking townhomes the stove is always placed against an interior wall. The ducting for the range hood is square and travels inside the stud bay instead of they typical round pipe heading straight out the top of the hood into the ceiling.

How good/bad of an idea is it to use this square in-stud duct design?

tia.

@Kris, there’s nothing

@Kris, there’s nothing intrinsically bad about square (actually rectangular, typically 3.25 x 10) exhaust ducting. The hood will be down-rated a bit but if it’s sized correctly to begin with, all of that is taken into account. In my experience, most hoods move more air than necessary to get the job done.

BTW, mounting a range & hood on an interior wall doesn’t necessarily require routing the duct through stud cavities. It can be vented up through an upper cabinet. From there, the duct can turn horizontal if there’s conditioned space above.

Thanks David,

Thanks David,

I guess the builder is trying to save a couple of hundred dollars by use the rectangular, out the back, stud cavity ducting.

Well, that sounds reasonable,

Well, that sounds reasonable, Sean. But yesterday I took a walk through the second house on the site, which just got framed last week. The I-joists are 14″ deep and made by Boise Cascade. According to BC’s own documents (https://p.widencdn.net/pclohu), the holes shown here are OK. Also, judging by what I saw, it seemed the holes were precut but I couldn’t find anything on the BC website about them offering precut I-joists.