My 24 Hour Mistake in 2×4 Wall Calculations

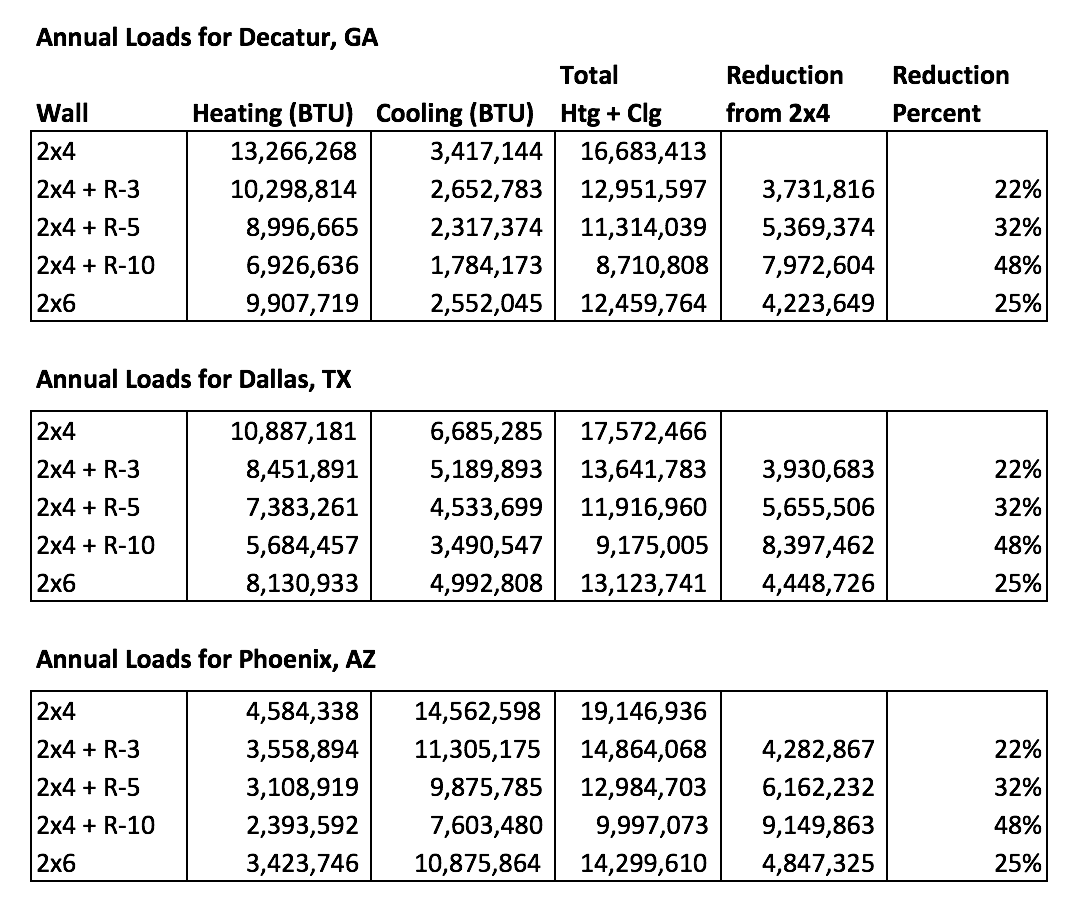

Remember that article I wrote last week? You know, the one about how much you might save if you go beyond a standard 2×4 wall in a warm climate? I showed three tables in the article. The first was a list of the whole-wall R-values for the standard 2×4 wall and three better walls. The second showed the design loads for HVAC sizing for those four walls in three different locations. And then there was the third. In that one I showed the annual heating and cooling loads for the four walls plus one more.

One of those tables, however, had a mistake in it. When I first did the calculations in a spreadsheet, I thought there must be a mistake because the numbers seemed too low. But I checked and rechecked my work and just couldn’t find it. So I convinced myself it was correct and published the article anyway. A commenter on the article at Green Building Advisor, though, pointed out that my results were too low, so I went back and found the mistake.

Here’s the corrected table:

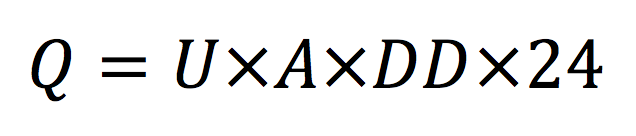

This was the third table in the previous article. The mistake was that I had forgotten to multiply by 24 to convert between hours and days in the calculation. Here’s the equation I should have used:

The version of this equation I used in the previous article left the x24 off the end because that’s really just a unit conversion. But I should have known better. Fortunately, I didn’t make that mistake in my article on diminishing returns, which relies on the same calculation.

Anyway, the new table above makes things look a whole lot better for going beyond standard 2×4 walls. Twenty-four times better as a matter of fact. Using the incorrect results, I had stated in the last article that the annual reduction of heat transfer through the walls in the best case would have been about 100 kilowatt-hours. The best case now is about a 2,700 kWh reduction. (The conversion here is 1 kWh = 3,412 BTU.)

But I’ve got some bad news for you. If you do all your heating and cooling with a heat pump, you can move all those kilowatt-hours using even fewer kilowatt-hours. Generally, you can move about 3 kWh at a cost of 1 kWh. (The coefficient of performance, or COP, for a typical heat pump is about 3.) So in that best case of a 2,700 kWh reduction, you’d have to pay for only about 900 kWh. At $0.15 per kWh, your savings would be about $135 per year. That’s not too bad, though. Right?

Better news, though, is that if you heat with an inefficient furnace, you’ll have to buy more BTUs of natural gas than you lose through the walls. In the case with the most reduction in heating load (Decatur, GA), you cut the heat loss by about 3 million BTUs. If your furnace is 80%, you’ve got to buy 3,000,000 ÷ 0.8 = 3,750,000 BTUs. That translates to 37.5 therms.

The bad news about that is the price of gas is really low. In Decatur, we pay less than $0.60 per therm. So you’re looking at about $20 per year in savings there.

But the good news is: that’s just the heating side. You’ll save another $20 or so on the cooling side.

And the bad news there is that you’re still saving only about $40 per year total.

But the other good news is that we’ve just scratched the surface here. I’ve compared different walls that all have the same framing factor. What if we throw in some advanced framing at the same time? Could we cut our heating & cooling loads by half for very little cost? In that last article, David Butler wrote in the comments, “a 2×6 wall 24-oc is not much more expensive than 2×4 16-oc including insulation. When you do optimal-value engineering, it’s clear that 2×6 24-oc should be the baseline for all other assemblies.”

More to come on this topic. Watch this space.

Related Articles

Flat or Lumpy – How Would You Like Your Insulation?

Attic Stairs – A Mind-Blowing Hole in Your Building Envelope

How to Grade the Installation Quality of Insulation

NOTE: Comments are moderated. Your comment will not appear below until approved.

This Post Has 12 Comments

Comments are closed.

1. That’s the value of being

1. That’s the value of being brave enough to put your stuff out there for all to see and critique. Good on you, Allison.

2. So this is just conductive heat lost through cavities? Not considering framing or fenestrations?

3. Air source heat pumps may average a COP of 3 in warmer climates but that gets dragged down hard by sub ~10degf time if folks live where that happens.

@Bob, Allison’s article is

@Bob, Allison’s article is specific to warm climates. However, I wanted to point out that heat pumps still make a lot of sense in cold climates if there’s no access to cheap natural gas. Heat pumps are gaining traction in places like Maine and even Alaska.

Keep in mind that the colder the climate, the more heating hours there are above freezing, where heat pumps shine. But even at 0F, a mid-efficiency heat pump produces around 40% of nameplate capacity at a COP of ~2.0, so it still costs less per BTU of heat delivered than any alternative to natural gas. It’s just a matter of choosing the most economical supplemental heat (electric vs. fossil fuel), which depends on relative local energy costs.

1. Thanks, Bob!

1. Thanks, Bob!

2. Well, there’s a lot packed into those two questions. The calculation is based on the equation for conduction, but the actual physics involves conduction, convections, and radiation. All three modes are in play as heat moves from the warmer to the cooler side of a wall. And no, it’s not just what happens through the cavities. The heat flow through the framing is included above, but not through fenestration. In the first article I mentioned using a framing factor of 23%.

3. What David said in his reply. I was just looking at a paper about heat pumps in Vermont and, yes, the COP drops with the temperature, but even at 0° F, the COP is still at about 2. But as David said, there’s still a whole lot of heating hours that happen at higher temperatures.

Thank you for the response,

Thank you for the response, and David too of course. First, let it be known that I’m a huge fan of ASHPs, just an even bigger fan of whole truths. I completely get that they’re a great option and perform well in cold climates as well. And I’m not a fan of natural gas (ran into way too many unsafe homes as an energy advisor years ago, and follow Josh Fox’s twitter for too long). Anyway, not to take merit away from split systems, but the whole truth is that if you’re pointing to an ASHP system that has a COP of 2 at 10°F, it’s probably a single zone system (one compressor, one zone/AHU) – and that might be a supplemental installation in some homes north of DC, but it’s not as common as homes with 3-4 air handlers per compressor (multi-zone). It’s tough to find the COP numbers published for each unit with a variety of OATs, but here’s an example (http://meus1.mylinkdrive.com/files/M-Series_Engineering_Manual.pdf) the COP is 2.4 at 17°F. Perhaps I can dig through some old files and find the data to show COPs at more temps. Anyway, if you’re talking about single zone systems, then we’re on the same page, just going for full truth. Or are you talking about ducted systems?

@Bob, as noted in my post, 2

@Bob, as noted in my post, 2.0 COP @ 0F or thereabouts is typical of ‘mid efficiency’ heat pumps. Of course higher efficiency models are available. If you have the expanded performance tables for a heat pump, you can easily calculate the COP at any BIN temperature, although that’s getting way beyond the subject of this article.

BTW, 2-pipe multi-split heat pumps such as the M-Series you linked, by definition, are less efficient than single-splits. Moreover, smaller systems are generally more efficient than larger systems. Therefore, multiple small 1:1 systems will always be more efficient than large 2-pipe multi-splits, and may even cost less depending on specific models and # of zones.

That’s fair. Thanks for

That’s fair. Thanks for engaging on the topic and sorry for opening the extra can of worms. I feel better that we’ve at least established that the reference is for single zone systems. Perhaps on the hypothetical ASHP article you can share an example of a mid-efficiency model getting cop2 at 0F and also something better, rendering that the mid-efficiency option. I still suspect those units may be the peak and not the middle. With respect and appreciation, Bob.

I guess this is why codes in

I guess this is why codes in the S/E seem to focus more on air sealing vs exterior insulation. Pity that the savings with additional exterior insulation is so paltry.

Would you still recommend the 2×4 + R10 wall? My guess is that you’d say 2×6 @ 24″ oc.

JC, at least the savings are

JC, at least the savings are better than I showed last week with my incorrect calculations. As David Butler said in the comments of my last article, a 2×6 wall with advanced framing can be done for about the same cost as a standard 2×4 wall. What I’d recommend would depend on to whom I was making the recommendation. Someone who’s more interested in reducing their carbon footprint and is willing to pay a little extra for a better enclosure would probably be willing to go for the wall with exterior continuous insulation, maybe even a 2×6 wall with exterior insulation. But as I said in the last article, you’d need to look at what other opportunities might be available. Windows and ceilings and ducts might be present better opportunites for saving than beefing up the walls.

Glad you caught the error. It

Glad you caught the error. It also explains why the air sealing/insulation-on-the-outside makes the most sense for doing a deep-energy retrofit of conventionally-framed houses (of which there are millions). Seems like a good house flipping opportunity if you can get the original at a substantially-reduced price.

Great follow up article and

Great follow up article and this all now makes sense to me.

Good article and good catch

Good article and good catch on the 24 mistake. I just did a presentation with slides on the cost of fuel break down and heat loss analysis. This was to show different heating systems, their run costs, comfort levels and their upfront costs. I like how your breaking it down by the assemblies looking at how much savings one may get. When selling comfort, sometimes the numbers don’t show the real life results. Kind of like comparing an 82% cast iron boiler to a 96% mod-con boiler. The difference is more then a few points (due to modulation). Feel free to reach out to me if you have free time. MOE H

The main advantage would be

The main advantage would be cold climate as heating costs are higher than cooling costs, and more critical as no heat would cause damage (frozen pipes) and possible injury more than heat. However, 2×4 wall/26 wall vs a wall with exterior foam has another difference. The foam is typically taped so the result is higher R value but lower air infiltration and, critical also, significantly lower wind washing of the insulation in the cavity. So the effect of the cavity insulation with the exterior foam is increased. Real world vs lab is hard to quantify and published R values are lab results, but in the real world the foam does add many positive aspects above the calculated increased R value.