Blower Doors and Body Mass Index

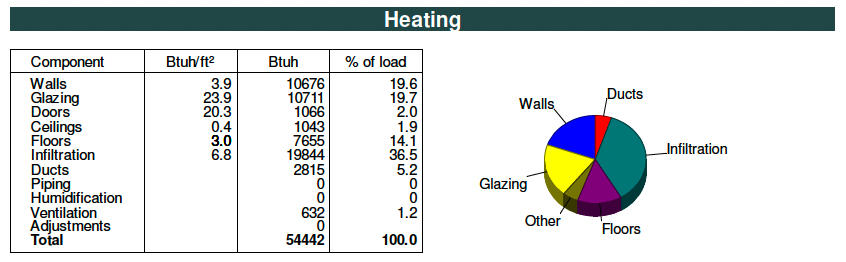

Let’s talk about the blower door today. It’s one of the most important tools for analyzing the performance of a house. And it’s THE tool for quantifying air leakage. That, of course, is related to energy use, comfort, indoor air quality, noise, and durability of a home. The screenshot below shows that air leakage (infiltration) is the largest part of the heating load in this older house in Atlanta.

But putting the results in proper context can be tricky. So here I’ll start with an explanation of what a blower door does and what it measures. Then I’ll show you how blower doors are related to body mass index. Really!

The physics behind blower doors

A house is not a vacuum chamber. It has holes that leak air. That’s true for even those homes with extreme airtightness, like the ones that meet Passive House requirements.

There’s a lot of interesting physics around air leakage. Here are the essentials you need to know to understand blower door testing:

- Air moves from one place to another (e.g., indoors to outdoors) only when there’s both a pathway and a pressure difference.

- When a unit of air leaves the building, an equal unit comes in somewhere else to replace it. So when a cubic foot (or cubic meter) of air leaks out, another cubic foot (or cubic meter) leaks in. (It’s not strictly true all the time because there are brief moments of non-equilibrium flow.)

And that’s really all you need to know to understand what blower doors do.

What a blower door does

A house has holes in the building enclosure. Those holes are the pathways.

The pressure differences that drive air through the holes arise from one of three sources: wind, stack effect, and mechanical systems (exhaust fans, duct leakage…). For now, all you need to know is that houses will always have pathways and pressure differences are almost always present, too.

![How a blower door works [Courtesy of The Energy Conservatory]](https://www.energyvanguard.com/wp-content/uploads/2025/06/how-blower-door-works-TEC.png)

The last step is measuring how much air is moving through the fan. We can do that because companies like The Energy Conservatory and Retrotec have spent the past several decades perfecting this important tool. A blower door has a calibrated fan, and that’s how we can tell how much air moves through it.

Blower door results

Let’s dig into what I just said, though, and see what it really means. Yes, a blower door tells you how much air moves through the fan when it’s running. But that’s not what it’s measuring directly. With the house at a given pressure difference (usually 50 pascals for a single point test), the pressure gauge (manometer) measures the pressure of the air going through the fan.

So here are the first and second level results you get from a blower door:

- Pressure of the air moving through the blower

- Air flow rate in cubic feet per minute, cubic meters per hour, or liters per second

The air flow rate is more useful than the pressure of the air stream. But it’s not a great way to compare one house to another or to a threshold you need to meet for the building code or program requirements. And that brings us close to the issue of body mass index.

A weighty matter

Here’s how I described the problem in my book:

The only problem with using the air flow rate at 50 Pascals is that it doesn’t factor in the size of the house. If I told you, for example, that I have a friend who weighs 150 pounds (68 kg), you don’t know anything about whether he’s morbidly obese, anorexically skinny, or somewhere in between. If I tell you he’s 7 feet tall (2.1 m), you know he’s skinny. The body mass index is a single number that accounts for both weight and height, and we need something similar for air leakage.

The primary way to convert an infiltration air flow rate to something we can use to compare one house to another is air changes per hour (ACH). Basically, it’s just changing the units. If we start with cubic feet per minute, we change cubic feet to air changes and minutes to hours. The first conversion assumes that one air change equals the volume inside the house. The second is 60 minutes equal one hour.

Pretty easy, eh? Now at least we have something that allows us to compare one house to another.

Stepping it up

The next step is specifying the pressure at which those air changes per hour happen. With the blower door keeping the house at a pressure difference of 50 pascals (Pa), we have the—wait for it—air changes per hour at 50 Pa, or ACH50. This is what most building codes and programs specify. Georgia, for example, requires all new homes to be tested and achieve an airtightness of less than 5 ACH50.

Then there’s trying to find out what the air leakage rate would be at more normal house pressures. You’ll sometimes see mention of “natural air changes per hour,” or ACHnat. It’s a rough estimate, but we need to be able to do that for heating and cooling load calculations and energy modeling.

But there’s an even better way to characterize the results you get from a blower door test. Yes, air changes per hour does let you compare one house to another, but there’s a flaw. It’s based on volume, but leakage happens at the surface. That leads to an unfair advantage for larger houses. (See my articles on this topic for more detail.)

The answer to that problem is to use surface area of the air barrier instead of volume inside the house. The result there would be given in terms of the blower door air leakage rate (cubic feet per minute or cubic meters per hour) and surface are (square feet or square meters). For example, Phius requires most projects to come in at 0.06 cfm50 per square foot of enclosure (air barrier).

And there you have it. The air flow rate from a blower door test (e.g., cfm50) is like weight. When you factor in the volume or surface area, now you’re doing something like body mass index. But of course, I’ve mentioned a few ways to do the body mass index conversion with blower door results, and there are even more. So you probably won’t be surprised that there are alternatives to body mass index, too.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can follow Allison on LinkedIn and subscribe to Energy Vanguard’s weekly newsletter and YouTube channel.

Related Articles

How Airtight Can You Make an Older House?

Infiltration Occurs at the Surface, Not in the Volume

It’s the Hole – Understanding What a Blower Door Is for

Comments are welcome and moderated. Your comment will appear below after approval. To control spam, we close comments after one year.

Dear Allison: I agree completely – a blower door test is essential, particularly for older homes, if you want to save money on your HVAC bill. We ran a blower door test on our deeply remodeled and sealed home in Massachusetts, and I was surprised by the leakage rate. Then I remembered the hole in the wall from the old chimney we took down, in the basement. I stuffed a beach towel in it and voila! The low rate I expected. Also make sure all of your windows are closed tight, and cover/seal bath fans which may not have a ‘flap’ (or good seal) to block air moving into the house. Your chimney is also a major culprit, if you don’t have a sealed firebox, tightly sealed damper or cap on the top that you can close.

Mark: Yeah, blower door testing can reveal problems you didn’t know you had. I hope you replaced the beach towel with something that’s going to give you a more permanent air seal.

As engineers, we often like to normalize things for comparison purposes. We often talk about energy use or air leakage per unit volume, unit floor area, or unit surface area. We can argue which is more appropriate. When it comes to energy codes and standards, why do we normalize energy usage at all? Why do we allow bigger houses to consume more energy? Is that the proper way to regulate energy usage for societal purposes, i.e., rich people who can afford bigger houses get to consume more energy?

Roy: Those are great questions. I remember talking to the head of the ENERGY STAR new homes program over 20 years ago about using the same criteria to certify houses no matter the size. Eventually, they did make it harder to qualify with larger homes. In the US, societal purposes take a backseat to individualism, so I don’t see that changing anytime soon.

Because the energy efficiency codes are based on achieving a level of efficiency that is cost effective. And I wouldn’t worry, there’s so much potential for improvement within the limits of cost effectiveness.

I am not sure I understand/agree about the larger volume building having an advantage with blower door numbers. Smaller homes have less exposed shell for leaks, while a larger home has greater exposed shell. I am sure the relationship is not linear due some homes having a lot of ins and outs with those walls. This would increase their exposed shell without a lot of increased volume. ACH still seems to work pretty well. As long as mine are under .5ACH50, I have done my job.

Thomas: ACH absolutely does give a bias toward larger homes. Let me see if I can explain it more simply than I did in the two articles I wrote on this topic in 2010.

The holes are at the surface, not spread throughout the volume of the house. That means the density of holes on the surface should scale with the size of the surface. But volume increases faster than surface area. So a larger house can have a higher surface density of holes (cfm50 per square foot of enclosure) and still meet the same ACH50 target.

I know this is a difficult concept to grasp, so I’ll work on an example with numbers and publish it later.

Dear Allison: Here is a simple explanation, with basic geometry, for your readers. Let’s look at the rate at which the volume of a cube increases vs the area. Volume increases at twice the rate of area:

> 2′ on a side: volume = 8 cubic feet, surface area on 6 sides = 24 square feet

> 4′ on a side: volume = 64 cubic feet (8x previous), surface area = 96 square feet (4x previous)

> 8′ on a side: volume = 512 cubic feet (8x previous), surface area = 384 square feet (4x previous)

To extend this further, if you want to minimized the surface area to volume ratio (A/V) for a house, you should build a sphere. If you want to stick with flat and orthogonal surfaces, then you want to build a cube. Most people don’t seem to like cubical designs for various aesthetic and functional reasons. For instance, a cubical house with 1728 sq. ft. of total floor area would be 24′ wide, 24′ long, and 24′ tall (3 stories). If you make the floor plan more rectangular (higher length to width ratio for the same floor area), you will have a higher A/V. If you only have one story, you will have a higher A/V compared to a two-story house with the same total floor area. Most home energy and air tightness metrics don’t give credit for houses that have more optimal shapes in terms of A/V since they are based on floor area or volume.

I have never seen much value in ACH. It is mainly a result of early home air leakage tests that were done with tracer gas decay methods where ACH was a directly calculated output from the measured decay rate. If you want to determine the actual amount of air leakage (cfm), you need to determine the internal air volume of the house and multiply it by ACH. The downside of tracer gas decay methods are that they are slow and the outcome is dependent on various weather factors as described by Allison. Blower test methods were developed to be a faster and more repeatable measurement of the air “tightness” of the house (not its “leakage”) and is mainly used for comparative purposes. I think that a better metric for comparison and regulation would be CFM50 per square foot of floor area, not ACH50.