6 Reasons to Do Single-Head Mini-Split Heat Pumps

![Nine Individual One-to-one Mini-split Heat Pump Outdoor Units [Photo Courtesy Of Jonah Richard]](https://www.energyvanguard.com/wp-content/uploads/2023/03/mini-split-heat-pump-outdoor-unit-one-to-one-1000.jpg)

When it comes to mini-split heat pumps, you get to play by different rules. With a traditional split system heat pump (or air conditioner), there’s one outdoor unit and one indoor unit. But with mini-splits, you have the option of connecting multiple indoor units to a single outdoor unit. Sometimes you’ll see this called a multi-split heat pump. Interesting idea, eh? Sounds like it might save money and make things simpler to have only one outdoor unit. But what are the downsides?

This question came up on LinkedIn recently when Jonah Richard posted the photo above showing nine outdoor units connected to nine independent indoor units. He said they set it up that way to separate the utilities for the eight apartments and one retail space. I commented about the advantages of going with one-to-one mini-splits, and that started a good discussion. Below are the reasons we try to get our HVAC design clients to go with one-to-one units when they can.

1. Temperature control

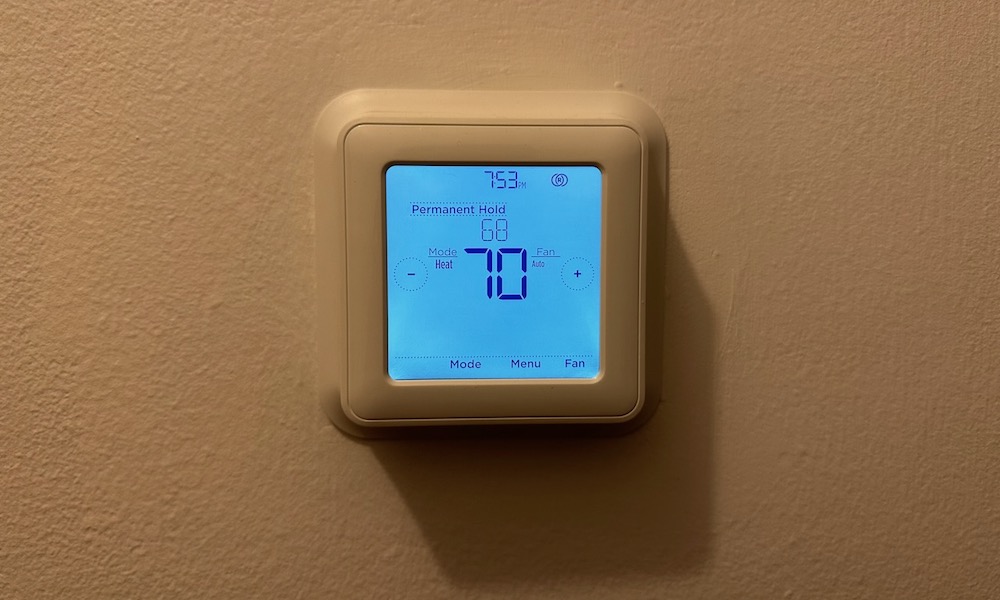

Refrigerant flows to indoor units even when they’re not calling for heating or cooling. The main heat pump in my house is connected to two ducted air handlers, and I’ve noticed this happening. When I go to bed at night, I have to remember to turn down both thermostats to get the bedroom to be cool enough while I’m sleeping. Otherwise, when the refrigerant is flowing to the common area air handler, it also flows to the bedrooms air handler. The photo below shows the effect of this on my bedroom thermostat, which is 2 degrees higher than the setpoint of 68 °F.

2. Resilience through redundancy

With one outdoor unit, if it goes out, all indoor units are out, too. Having multiple independent heat pumps adds resilience. Unless they all go out, you can heat or cool at least part of the house with the remaining operable units. It’s always good to have a backup!

3. Better control of low load heating and cooling

The turndown ratio of a mini-split heat pump is one of its most important specifications. If it can lower its capacity to 25% of the full capacity, that gives it a turndown ratio of 4 to 1 because the maximum capacity is 4 times larger than the lowest capacity.

Let’s say you have a multi-split heat pump with a capacity of 30,000 BTU per hour. It has a 4-to-1 turndown ratio. Attached to this outdoor unit are five indoor heads, each with a capacity of 6,000 BTU per hour. The lowest capacity that outdoor unit is able to provide is 25% of 30,000 BTU/hr, or 7,500 BTU/hr. On a part-load day when there’s not much demand for heating or cooling, the indoor units together may need to put out a small fraction of that minimum capacity.

4. When one unit is calling for cooling, the other can be heating

Sometimes one part of the house may need cooling at the same time another part needs heating. With standard residential mini-split heat pumps, a multi-split system with one outdoor unit cannot do simultaneous heating and cooling.

There are units that do that, but they’re used for larger buildings, mostly commercial. It’s a really technology that pulls heat from the part of the building that needs cooling and sends that heat to the part of the building that needs heating. When that occurs, the refrigerant can bypass the outdoor unit, and it’s really a type of heat recovery.

But if you have separate outdoor units, you CAN do simultaneous heating cooling. There’s no recovery because both outdoor units will be running. But it will meet the needs of the house.

5. Reduced thermostat confusion

Having only one outdoor unit controlled by two or more thermostats can lead to confused or frustrated occupants. It’s not hard to forget the constraint on all indoor units needing to be set for the same mode, heating or cooling. I’ve done it myself at my house. It didn’t take me long to figure it out, but HVAC companies get calls from people who think the system is broken.

They set a thermostat to cooling, for example, while the other thermostat on the same outdoor unit is set to heating. The cooling never arrives, so they think something’s wrong. Experienced HVAC technicians find the problem quickly, but separate outdoor units would prevent it.

6. Simpler installation

One-to-one mini-split installations are simpler. The outdoor unit works in sync with the indoor unit and never has to split refrigerant in two or more line sets. It also can allow for less total refrigerant line length if you can place the outdoor units closer to where the heads are installed indoors. That means less refrigerant, too.

Sum and substance

Some of our designs do include multi-splits. Occasionally, the constraints of a project force us to do far more with one outdoor unit than we’d prefer. A four-story townhouse, for example, ended up with six indoor units on a single outdoor unit and three more indoor units on a second outdoor unit. Generally, though, we aim for one-to-one setups or at least as few indoor units as we can get for each outdoor unit. The advantages above are significant.

And what about cost? You may think it’s more expensive to have more outdoor units. But that’s not necessarily true. The cost could be the same as a multi-split system design for the same house. It might even be lower.

So, if you’re planning for mini-split heat pumps, don’t automatically try to do it all with one outdoor unit.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a popular book on building science. He also writes the Energy Vanguard Blog. You can follow him on Twitter at @EnergyVanguard.

Related Articles

What Is a Mini-Split Heat Pump?

Heat Pumps, Auxiliary Heat, and Resilience

What’s the Name of The Outdoor Part of a Heat Pump?

Photo of 9 outdoor mini-split heat pump units courtesy of Jonah Richard.

Comments are moderated. Your comment will not appear below until approved.

This Post Has 80 Comments

Comments are closed.

What a great article! Well done and all great points.

I also tend to lean toward single units over a system with multiple heads as usually single units are cheaper and personally I like individual systems. If one goes down it doesn’t take everything down and it’s far cheaper to replace one unit than a multi system.

As for brand I do like allot of what Mitsu does but in the real world it doesn’t make sense to use them over the far far cheaper other brands. Too long to go through explaining it all but there are times when you are better off with the cheaper version of stuff than the more expensive ones in the long run.

Basically minisplits even mitsus are considered non repairable like a tesla after a minor accident. And the mitsus don’t prove to be a better ROI than the other units on the market for much less.

Also the humidity control aspect of minisplits is really not very good and is a known issue with them. Basically it ends up just cooling to a lower temp. It’s the same problem that high efficiency conventional units have. They run long cycles with a warmer coil so they don’t remove as much moisture as a an older style system that runs shorter cycles but with a colder coil that wrings the moisture out of the air much faster at the beginning of it’s cycle before it starts to remove the sensible heat.

As for redundancy and the uninformed comment about the Tx which I see you have now removed for it being incorrect. An electric minisplit doesn’t do you any good when you have no power. Gas heat is the ideal redundancy in the winter because it requires no or little electricity. This is why places like Northern CA and other areas of the country that routinely loose power for weeks at a time vs a day yet are never chastised for it…

Until mini split manufacturers (I’m talking to you Mitsubishi) stop sunsetting models every few years and make it possible to connect an older but fully functioning inside unit to a new outside component, the efficiency gained from minisplits will never come close to the full replacement cost of both units every 7-8 years. No replacement parts. No techs willing to work on older units. $20k down the drain. Never again

You had to replace everything after 7 years? I put mine in the 2017 and fingers crossed I’ve had no issues

I have 4 in a 3 bedroom house and it’s awsom even my electric bill stays around 60-70.00 a month except the 2 hot months I did mine in 2018 and never any issues

My brand new system has a 12 year warranty from Mitsubishi 👀

So what you’re saying is that the Mitsu units are unreliable.

I’m a custom home builder in Nashville, and we have had an inordinate amount of issues with mitsubishi mini-splits. Ducted and ductless both. Installed over the years by two reputable companies that have good relationships with Mitsubishi, but in the end I have been left hanging out to dry more often than not by a company that does not stand by their product. And I don’t have enough time to get into the mold issues with wall mounted mini’s, but regardless of brand, if you live in a hot/humid climate your unit absolutely will grow mold without regular cleanings. I’ve seen it all over the world at this point. I drank the kool aid early on, but no more mini-splits for me.

YES!!! This is not high tech. They can make advanced tech while maintaining back compatibility for the expected 15+ year expected.life

Well done Allison.

I’ve specified two (2) multi-splits in my life time after seeing many of these same disadvantages.

Since 7 is a complete number, biblically speaking, I would add Line Set Connection Confusion. When you throw in #5 (thermostat confusion) with #7 you get ………….. an all day diagnostic experience. Its tempting to add #8 i.e. +$$$ for multi-port units. But I will stick with by Biblical upbringing.

I have limited experience with multi-splits, but are you sure that refrigerant runs though all of the indoor units when the compressor is running? That would seem like a dumb design to me for various reasons. I would guess that when you have one zone set at a lower temperature than another that there might be natural air flow between the zones that is causing the lower-set point zone to not drop in temperature as fast you want.

If a multi-split system is designed properly, you should get better efficiency at part load under at least some conditions since you have a much larger outdoor coil available then you would with multiple single-split systems when only one zone is operating.

Having separate single-split systems running in different modes in the same dwelling unit could result in unexpected things happening. My house has two ducted systems, one upstairs and one downstairs. If the downstairs unit ends up in heating mode with the upstairs unit in cooling mode, they both end up running at full capacity with a tornado in the stairwell. All it does is generate entropy.

Yes

They need to keep some refrigerant flowing to the “off” units to keep the system lubricated and to prevent refrigerant from pooling in the off unit. However, there appears to be meaningful differences in how much refrigerant is circulated depending on the system and the type of control valve used.

Sam, I don’t really understand the lubrication issue, especially since conventional single-split systems have long off times without lubrication issue. However, it does make sense that unused indoor units would fill with liquid during heating mode unless you have a gas valve for each indoor unit that can be switched off.

Roy, it’s an operation characteristic of inverters which don’t have sufficient velocity in the suction line to return oil to the compressor in lower frequencies. This does happen with conventional compressors which always run the same refrigerant velocity. Some inverter units have algorithms built in the inverter controls that bump the compressor up to a higher speed at selected intervals just to assure oil return.

I understand that low refrigerant flows result in oil not returning to the compressor, but I don’t see how that is an issue when there is no flow.

The system does allow refrigerant flow to all indoor heads, the valves in the equipment never fully close. This is by design… this is how it was explained to me by a technical trainer years ago. If you have one 30,000 btu outdoor unit and say three 9,000 btu indoor units on a system for a house but only have one indoor unit needing heat at a given time, high side pressure would go way to high if the other two indoor units were fully closed off. So there is a little bleed by of refrigerant to avoid excessive high side pressure and allows for proper system operation. There might be some new technology out there that has overcome this design issue, but I have not come across it yet.

I’m a refrigeration mechanic I’m going list all major factors with low load situations you could look it up these things all put together could assist in understanding one out one in concept

1 oil return oil is ingrained in the refrigerant so we try to maintain surten live velocities

2 refrigerant migration refrigerant will migrate to the coldest zone some times that can be the branch pipping witch can cause a short on pressure at the compressor suction

3 ineffective defrost when there is low in door Temps set in the heating mode defrost of the outdoor unit can become less efffect thus being longer or more often in humid climates keep this in mind

I’m not a fan of mini splits, there is still the need of a duct system to control IAQ.

While it’s sensible to use your duct system to help with IAQ if you have them, you can certainly address it without them.

This is true, you can have a single room ERV, along with a MERV 13 or greater air cleaner in each occupied room of the house, except the kitchen, where a properly sized range hood may work. The problem is the cost to control IAQ without a central duct system is very high. So, what is the benefit of a mini split?

You don’t get any filtration or ventilation when the HVAC system isn’t heating or cooling if everything goes though one duct system.

I always used variable speed air handlers and run continuous fan, this dilutes CO2 in occupied spaces and the air is always filtered. The air is further diluted with outdoor, fresh air provided by an ERV, but only when sensors call for it, monitoring VOC’s and CO2.

Paul, I like to hear your ideas on that, if you’re willing to share.

I went with a full sized heat pump when we replaced our a/c system, we looked at the mini splits but the difference in cost was much higher because or the lack of non-visible mounting points.

As I’m writing this we are on our backup generator power due to an outage. Our new Lennox “solar ready” heat pump doesn’t like the generator power and won’t start the heat pump. The backup furnace and blower works so it’s the condensing unit. Any idea if this is a common problem with the new “electronic” controlled variable speed equipment and if it affects mini- splits?

I’m in Texas so this is a concern.

David, you should look into adding the Micro-Air Easy Start 364 soft start switch gear to your heat pump. This will reduce the LRA at startup. Making it easier for generator or solar power systems to run heat pumps. Ive seen examples of it reducing the LRA on a 3.5 ton unit from 124 to 26.4.

You need an “Emerson SecureStart” softstart to run a unitary psc system on a generator.

I had a soft start on my old Goodman unit and it worked fine. This is a Lennox variable speed it’s only supposed to pull 16 amps to start. It’s not even trying to start. Even the Lennox thermostat has a tiny yellow/red led at the top edge that is strobing to the rhythm of the generator. Now I think the mini split might have been a better idea to allow a smaller inverter gen to run one unit in an emergency.

“Unless they all go out, you can heat or cool at least part of the house with the remaining operable units. It’s always good to have a backup! Texans who lost power in the big winter storm of 2021 have a good appreciation of that fact now.”

You are right about that but it was days of power and water outages as the primary concern. Many areas were iced-in particularly those living in hill country. Having a backup generator was the best solution, ideally fed by propane since even ng pumping was impacted. I keep a mini-unitary in my garage, otherwise known as a 8,200 btu window unit that will run on a small portable generator as long the gas cans hold out. Propane generators have sold well since.

I am a little confused. Reason #2: when the power is off wouldn’t all units be off whether single outdoor or multiple outdoor units? Resiliency would come from fewer total failures coming at the near end of life for the the heat pumps. Also, I imagine the the smaller heat pumps having better life spans. Is that the case?

Otherwise a wonderful article and convincing. Thank you for sharing.

John: Sorry, my mention of the Texas power outage of 2021 didn’t make sense there, so I’ve deleted it. You’re right that if the grid goes down, all units are off. The kind of resilience you get with redundancy is still having the ability to heat or cool part of the house when one unit goes down.

I can think of a few reasons why a 1:1 outdoor unit to indoor unit ratio might not be a great idea for everyone:

1) Space. You have to find somewhere to mount all those outdoor units.

2) Aesthetics. Having 3, 4, 5, 6 outdoor units increases the “ugly factor” (this and reason 1 are primarily only issues for single family homes).

3) Increased likelihood of something failing. While the system may overall be simpler and easier to troubleshoot, having many more compressors, fans, control boards, etc. is going to increase the chance of something failing. Though granted at least there’s little chance of the entire system failing at once.

4) Noise. While I don’t know for sure, it seems possible that having multiple smaller compressors running at the same time might make more noise than one larger compressor. Curious if you have any experience with the noise levels of systems with multiple outdoor units.

How about the electrical cost to add another sub panel to wire up all the new breakers? If all outdoor units are running as pictures, would that max out a 200 amp service ?

Sizing for a load center is based on actual simultaneous load, not sum of the breakers, so while many small units would require more breaker positions than one larger unit, the total load would be very similar. There would be some additional cost if that meant you overflowed into a subpanel, but that might only add $1500 or so to the total cost.

I have a one-to-one mini split set up for my general living area ( living room and kitchen) and a multi-split setup for the three bedrooms. Looking back I would have rather had a one-to-one in each bedroom if I could set the outdoor units up to not look like a hotel. Simply because of humidity control. The indoor units are capable of throttling down to a much lower BTU in a one-to-one setup but when connected to one multi-split compressor they can only go as low as that compressor can. I think for my Mitsubishi the lowest is 6,000 BTUs. In a well insulated bedroom that cool quickly what ends up happening is the compressor shuts off but the fan keeps running and all that moisture on the coil gets shot back into the room. I’ve had a workaround done by using a Cielo breez controller which shuts the whole unit off when the set temp is reached. It works fine but you shouldn’t have to do that. I think in the one-to-one setup my FH series Mitsubishi’s can go down to 1800 BTUs

Don’t agree with this article, I have 1 unit system at home with 5 head and there is no air coming out on the head that is off. Lower noise from 1 unit and less possibility to have a gas leaking unit ,

How is the cost to run a 2 ton mini split compared to 4 6k separate units for instance.

Good article Allison. Having been an HVAC contractor and PE for over 25 years now if you knew the amount of refrigerant r410a that leaks out of these systems you would probably specify nothing but conventional equipment. Incidentally the single zone systems are better in this regard since there’s less flare connections with multi port boxes etc. It’s a great concept but until the refrigerant has changed to something with less gwp I would not use them and strive to keep the refrigerant as centralized as possible like air cooled packaged chillers for commercial, packaged dx for residential etc.

What if the flare connections were all redone when the system was installed?

I had a very similar situation as Chris. After reaching set temp, humidity rising and creating terrible stench. Multiple small indoor wall units on a single very large compressor. Mitsubishi and contractor worthless, did not understand what was happening. It was unusable and with odor being subjective, and specific conditions being met to recreate, a complete disaster to claim. Really tough to troubleshoot if something goes wrong. Way too many combinations of operation and settings of each unit to figure out what is happening.

This article is spot on. One to one is the only way to go, for all the reasons listed, and more. Had I read this before would have saved myself a real life nightmare.

I think one of the hardest parts about sizing these systems is the compromise between being oversized for heating, or oversized for cooling. In my climate (CO, zone 5, dry), all heatpumps are sized for heating, and are way oversized for cooling, but because it is dry, the short cycling doesn’t create the kind of humidity problems you get elsewhere. A humid region really needs a system that is just barely sized for the load so it can run continuously and actually drain off that condensation rather than have it immediately re-evaporate back into the air when the unit cycles. Not easy to solve – I think we need multisplit heatpumps with much lower turn-downs so cold/humid areas can prevent short cycling while still being sized for heating.

Is assume multi stage systems and inverter systems would eliminate the oversized issue.

I thought the same as well but I have some well insulated bedrooms and when you have one larger outside unit connected to multiple inside ones the inverter can only go down as low as the outside unit can handle. In other words I’m pretty sure my outside unit for the bedrooms can only go down to 6,000 BTUs, so if I have one bedroom unit running in the house running on that compressor it can only throttle down to 6000 BTUs. This will lead to the room cooling too quickly and probably not removing enough humidity. Whereas if I had a mini split set up with the same bedroom and same wall unit it would be able to throttle down a lot lower I think if I’m not mistaken down to either 1800 or 2,000 btus. Apologize if I’m not using correct terminology but I’m not an HVAC professional

I know Sensibo has controller units and I think the newer Mitsubishi’s have Wi-Fi built in but I used the cielo breez I mentioned. In the winter and heat mode I just leave the fan run continuously whether it’s trying to make temp or not. That helps distribute the heat. But the only solution for me in those bedrooms at least, in my main living area I don’t have the issue because I have a one-to-one mini split setup and it’s a bigger area so there’s a larger load on the unit plus it’s able to throttle down more being a mini split rather than a multi, is to have the Cielo run in comfy mode and you give it a spread to operate on and when it gets to the lower temperature it totally shuts the unit off. So the unit doesn’t come on and off too much I try to set the temp spread a good three or four degrees apart. Depending on how you like it let’s say the unit comes on at 74° and shuts off at 70°. That way the whole time the fans spinning the compressor is running in your dehumidifying and as soon as the unit reaches temperature the fan shuts off. The other thing you could do for smell is get some coil cleaner at a big box store and every month pull the filters out and spray the coil and soak it down. Also when needed I’ll remove the whole cover, squirrel cage fan etc and clean it out myself because mold can collected the units. Once I did that the humidity was under control and had no smells. Before that my accurate would sometimes show humidity in those rooms going up to 70% now it’s down around 50 all the time. Cheers

That stench is mold that has accumulated on your blower wheel and in the nooks and crannies of the unit. It is possible for you to take it apart and clean it yourself if you are handy and find the right youtube videos. Otherwise you have to call an hvac contractor with the right low pressure power washer to rinse it. But don’t get too optimistic on how effective that method is. The mold will come back fairly quickly depending on the time of year you clean it. Because wall mounted mini-splits are so bad at dehumidification and allow the blower wheel to accumulate moisture as it is typically below the dew point during the summer, it stays wet for several months out of the year leading to mold growth. The “filters” on the units allow so much crap in the air to move through the coils and fan all that dust and dirt sticks to the damp parts creating a food source for the mold. Mitsubishi knows this although their initial reaction when I called years ago was to say the problem had to be something specific to the houses I was building. Mitsubishi claimed to have never heard of this issue before.

No one to my knowledge has ever published the measured losses when using one outdoor unit to serve multiple indoor units. My experience with domestic hot water systems is that the losses can be substantial.

Prior reports for hot water systems serving multiple locations said, “Heat losses from storage tanks and recirculating hot water piping should be calculated and added to the recovery capacities shown.” And “in some cases as little as 20% of the energy supplied to the water heating system was actually used as hot water at the fixtures. The reason for this poor efficiency was probably the losses in the distribution system.”

There are “SOME” benefits

I install HVAC and heat recovery for a living the last 30 years. Nine air handlers for the Electrician Hass to charge nine times for each hook up.. depending on your area you’re gonna be somewhere around $100 an hour to $300 an hour plus for your electrician.

As a, HVAC contractor if you need 60,000 BTUs nine small 6000 BTU air handlers. If you get charged set up an commissioning and testing for each individual unit times nine..

That means myself and my employees have to drawn vacuum nine times. That means we have to leak test nine separate units.. that means we have to perform a high-pressure nitrogen Decay test nine times. I did mention we have to commission nine times instead of one time.. I can tell you right now that just the nine times commissioning process will cost more than an entire 60,000 BTU unit. That’s a fact I can take to the bank..

they make residential heat, recovery unit that do heating and cooling simultaneously. On top of that when in cooling mode, all that waste heat energy can be transferred to a hydronic Hydro unit that heats water for domestic heating at basically no cost because it’s the same waste heat that would’ve been ejected to the atmosphere through the outdoor coil. ..

As for the ability to heat and cool, it takes a lot of energy to make heat. So, as mentioned in the article, you were paying money to the energy company to produce heat with one unit at the same time you’re paying money to the energy company to cool with a separate unit.

With the heat recovery system, the money spent to the energy company to cool one space that waste heat gets transferred to the other part of the building for basically free without consuming more energy and transferred over to the other space.

As for individual thermostats, you just need one thermostat it’s a Smart stat that’s more like a iPad. You could program all your dates your times how many hours of run time change temperatures anytime you desire pre-programmed 7/24/365. There is no excuse to say individual thermostats are needed.. and you can toggle on or off the automatic, sensing feature that uses a infrared sensor. When you enter the room it turns it on, and when you leave it turns it off.

But I could tell you for a fact I would probably be charging an extra nine to $12,000 to install nine individual units. I don’t see how you’re going to recoup that energy savings.. and you don’t have heat recovery mode where are you utilize the heat from one part of the building and transferred to another part at the energy savings for free.

As for the refrigerant, flowing and cooling or making noise in other air handler’s all the time that is not the case with the VRF mini split systems that have the Evies electronic expansion valves, located in each and every air handler they do not constantly flow refrigerant through each head so that is not an issue here.

And in extreme cases, if you wanna pay for comfort, you can actually run a reheat system on a ducted air handler on a mini split so you can turn up the de humidification mode that most people do not know can be done.

Because it’s not really advertised.

This is the advantage of the heat recovery units that have the Hydro-Pack for heating water at the same time your cooling in the summertime, but you may want to have that extra Dehumidification without the extra expense of purchasing and installing a separate whole house. Dehumidifier..

You gonna

Which units are compatible with a domestic hot water system? I’d be very interested in that – a domestic pre-heat system would be an elegant solution to the short cycling in the moderate heating season that I’ll inevitably face.

What is the brand and model number for the residential VRF systems that do heat recovery?Didn’t know it was a thing below 60,000 btu and single phase…

I’ll have to look into those expansion valves… interesting.

No mention of the efficiency of one to one versus multi head. When I look at the Mitsubishi brochures the small 6k, 9k, 12k units all have crazy efficiency as compared to the multi head setups.

Yes that is true unfortunately when I had my system put in I didn’t realize the efficiency for the smaller wall units would not be as advertised when hooked up as a multi setup. So instead of like 30 to 33 seer for my bedroom units I’m more like 20

For point #1, you have to cut a jumper on the control board in the evaporator to shut off the blower while not calling for heat if you are using a wall mounted thermostat like an mhk2 stat. You can also do this for cooling with a different jumper. Just make sure your reading temps from the wall stat. Doing this will allow the system to not over heat a space while not calling.

I had read a few things about that. I like it running continuously when in heat mode but thought about doing the jumper for cool mode but as of now I’m not reading off of a wall thermostat. I imagine then I would have to have a wall thermostat for each individual unit in each bedroom and since I already have the Cielo controllers I’m not sure if it makes sense for me. So the way this would work I guess instead of having a spread of say 70 to 74° or whatever you would just set the temperature at whatever your preference is and the unit would come on and off more often? I guess there’s a built-in cushion on both sides of whatever temp you pick so it doesn’t come off and on every 5 minutes? Thanks

WARNING- philosophical rant coming. And this is nothing more than my opinion.

As I read through this thread, a picture forms in my head. Turn the clock forward 6 to 8 years and the poor homeowner wakes up with no heat on Christmas Day. He calls the installer servicer and they send Leroy out because the genius that put all sophistication in place is at his wife’s family hoe-down in the Keys. Leroy is a parts changer and all he sees is computer boards…..now the stage is set for a bad outcome.

I promise that this is a realistic view of the talent pool in my area. And it’s not getting any better. Plug and play, installation instruction videos (suggestions to Leroy cause he has 20 years experience) and self diagnostics will become more necessary as the talent pool is headed the wrong way.

I don’t see this scenario as fair to the consumer. That’s especially inequitable when we can heat and cool homes in my CZ 4 at 1 to 1.5 cents per ft2 per month with simpler solutions…

As Robert B says, buildings exist for people. It seems that sometimes we forget that small detail. Competent health professionals should treat the patient, not the MRI . I’m liking Occam’s Razor more and more these days.

“That’s especially inequitable when we can heat and cool homes in my CZ 4 at 1 to 1.5 cents per ft2 per month with simpler solutions…”

Exactly what I was thinking as well. A metric that is needed is operating costs per sqft. Which varies by location and the electric and gas market. Quality of complex hvac controls needs to match Toyota or Honda. Including standardized diagnostic tools. They are a long long way apart right now. And the cars are arguably in a harsher environment other than hvac’s grid power supply which is a conduit for surges and failures. But even grid power issues have solutions.

YES !!! Totally agree.

I have three heads on one pump, two on first floor, one for attic. In S Calif the attic often needs opposite of first floor. Next sys will have separate for attic, at least

Really want Wifi control and monitor for all units.

Here in Australia Mitsubishi Electric are one of the most reliable brands of units from splits, multi, residential ducted and commercial VRV, being a HVAC service tech for close to 30 years I can honestly say I’ve replaced very few parts on Mitsubishi Electric units..

Tech support and parts are awesome.

Not sure if units in USA are the same but maybe they are made somewhere else and thus quality is lower.

Good to hear. I’m not in the field but I’m in the States and I’ve heard the same

That’s how we did it. A 9000btu unit for the bedroom and a 24k one for the main living area. Buying 2 separate units is also less expensive than 1 larger one also.

While I see the benefit of being able to heat and cool different parts of a building at the same time it bothers me to think about all of the additional energy used to allow someone to have their cake and eat it too. Larger buildings with multiple floors could certainly benefit from this but as you already mentioned, that’s where the real magic of a VRF system comes in. Doing this in a house is likely an indicator that it’s simply too big. Trust that I see this happen first hand in my own modestly sized home (particularly on cold and sunny days) but I’d rather wait for the air within the envelope to mix naturally, than to cool the south facing sunny room and heat the north facing shaded room. On a related note, I’ve seen various buildings retrofitted with fans and ducts to move warm air from the top floor to the lowest floors and wondered if it is simply an act in futility or if you see any real value in this approach?

Great article as usual, Allison. I can see going either way. My main disadvantages for the one to one is electrical breaker, wire, conduit, outdoor disconnect cost and the aesthetic of the hotel look of several outdoor units. On the turn down issue stated a couple of times: Do the “one to one” heads know to turn down the fan speed to accomplish dehumidification with the greater turn ratios of the heat pump? Unless the thermostat is put into drying mode I suspect that 1800btuh cooling and still running a couple hundred CFM (<10FdeltaT) will not do any dehumidification anyway. I have a three head multi-split that has been operating flawlessly for 2+ years winter/summer CZ5 with no electric backup (and i hoping I'm not jinxing myself by saying that). My AC runs so little in the summer that I added a dehumidifcation unit in the basement, but I attribute that need to having built a tight (less than 1ACH50) house. I have only used the multi-split drying mode on the thermostats a couple of times and still not sure what it is controlling to temperature wise. I intend to do more testing with that this summer.

1. There are at least 3 manufacturers in North America who make Air-to-Water heat pumps which resolve several problems mentioned in this thread. They can make domestic hot water. The refrigeration system is small and confined entirely to the outdoor unit. They heat or cool an indoor buffer tank of water that can absorb part-load capacity. You can have up to 8 indoor units piped from the buffer tank with no field joints to increase the likelihood of an expensive R-410a leak with its GWP that is 2,085 times worse than CO2. Mitusbishi has a new Ecodan line using propane as a refrigerant that can make 167F hot water and would work in existing older homes with baseboard or radiator hot water systems. I have not heard when it will be available in the US, though, and the info I saw did not say it could do cooling.

2. Most of the cold weather multi-split specs I have looked at have a HSPF of 10.3, whereas their single zone counterparts are at 13. That’s a LOT better.

3. As of Jan 1, 2023, the EPA is using a new metric for heat pump efficiency called SEER2 and HSPF2. It more accurately reflects the actual seasonal performance and operating costs you can expect AND HSPF2 is about 15% lower than the old HSPF. SEER2 is 5% lower than the older SEER. So although you can’t seem to read an article about heat pumps that fails to say they are MUCH MORE EFFICIENT than combustion heaters, they aren’t as more-efficient as we used to think, as reflected in the new ratings. Saying a heat pump is more efficient than a fossil fuel heater IMPLIES that the heat pump will cost less to heat your home. But that depends on where you live and the relative cost of electricity and fossil fuel. In New England, for example. heat pumps cost MORE to operate than gas heat, and somewhat less than oil (and a lot less than propane). The new seasonal ratings that are intended to provide more accurate operating cost estimates indicate that operating costs are higher than we previously thought. So heat pumps are the only way to decarbonize our heating systems, but may not reduce operating costs.

Great comments Gene. I’ve practiced hydronics for 40 years, including some chiller systems for cooling/dehumdification. It’s a fascinating discussion above and great for me to learn how these HVAC systems operate in reality. I have some experience now with air to water hp using hydronic radiant ceilings-floors and doas system that includes an era and dehumidifier coil operating from the chiller. Seems like a lot of problems are solved if the sensible heating and cooling are done sensibly preferably with radiant panels with ventilation and dehumidification handled by air handling systems dedicated to those loads.

With a hydronic distribution system it’s easy to zone and interlock thermostats heating to cooling etc from a single compressor. A buffer tank allows for zoning and for even a single speed compressor to operate at it’s sweet spot. Placing a single unit larger “unit” outside in a convenient space will prevent the festooning of the outside of the building with compressors. There are real economies of scale to central systems over many small units in parallel. The mono bloc design of atw units provide for short factory charged refrigerant lines. I’ve had a 4 ton mono bloc chiller serving 3 air handlers on my commercial building. It’s almost 30 years old with no maintenance. (It scares me how much refrigerant is being used in these systems, especially the larger VRF systems – sooner or later it will end up in the atmosphere).

Anyway thanks to Allison for the education he is providing. Lots of good info by all. Things designers need to address in their systems. I’m learning a lot.

Gene, you mentioned propane as a refrigerant.

Yes, it has a wider working temperature range and carries more heat. Propane has a GWP of 3 vs 2088 for R410A (with CO2 as GWP of 1)

In Europe Viessmann manufactures some very cool ATW heat pumps that use propane as a refrigerant. As you say, they can make 167°f water at high COP. You can also make ice!

See https://www.viessmann.family/en/newsroom/solution-offering/the-new-generation-of-heat-pumps

Thanks for your comments Dale. It’s good to hear someone else interested in ATW heat pumps. I think they are the only way we can possibly convert the millions of northeast US homes with hot water boilers to heat pumps at a reasonable cost. A drop-in boiler replacement with a resistance backup heater in the indoor hot water buffer tank. It even has a little energy storage. I have experimented with low temperature hot water in my hot water baseboard heat, and found that when the outdoor temperature was in the low 30’s it could maintain temperature with 125F hot water supply, but it took 8 hours to recover from an 8 F night setback. My conclusion is that even a high temp heat pump could operate at medium temperatures for most hours, and just boot to its high temperature supply when recovering from night setback. Mini-splits also are not good at recovery from deep temperature setbacks, but that is seldom mentioned. So if you have to maintain comfort temperatures all hours of the day and night, you will have to supply more Btus (kWh) per year, which increases your operating costs. I think these high temperature heat pumps can avoid that problem. When they fail they can be removed and repaired in a warm refrigeration shop instead of in the snow. Plumbers can install them because they mostly need plumbing skills for the install, and perhaps a little carpentry, and we don’t have enough refrigeration technicians to do all the conversions we have to do to cool down the planet.

We had a leak of 5 pounds of R-410a from our multi-split that was equal to the global warming of the CO2 for burning gas in our boiler for a whole year. The propane monobloc heat pumps would avoid that. I hope the European manufacturers will soon be importing the Air-to- Water heat pumps here so we can have some choices. They have greater incentives for Europe because of the gas shortages, but those shortages affect gas prices here too. Viessman has a lot of distributors for boilers in the US so they at least have a strong presence here.

Don’t know if I’m talking about the same thing but I put in a HPWH that has electric resistance for backup but I keep it in heat pump mode only. I set the temperature to 140° and have a mixing valve right after the line leaves the tank lowering the temp to 120 going into the house. This serves two purposes, it helps prevent bacteria growth in the tank and it effectively gives you a larger tank

Good to know you Gene.

I have been a Viessmann distributor for over 35 years. We see lots of things they do in Europe that we can’t have, though with luck we will see their heat pumps soon. Viessmann is the world leader in energy technology. The Viessmann condensing boilers we work with now in NA are already capable of 20% hydrogen mix.

Even when I work with heat pumps I design central heating systems. My point in the post was to point out what I see as advantages to hydronic distribution systems including the ability to centrally heat and cool and zone etc. from a single heat pump or more than one in parallel located in a single place. The hydronic distribution system effectively eliminates the refrigerant piping while adding versatility and control. If de-humidification is needed, the same system can operate a chilled water coil in an air handler using mixed air or in dedicated outdoor air system that de-humidifies ventilation air then fed to an ERV.

I’m very concerned about the proliferation of these refrigerants. As you say the VRF systems or multi-splits are the most likely leakage problems as they require all of the field connections. Obviously I’m biased but it seems like the hvac industry has problems that could be easily and naturally solved with hydronics.

The refrigerants like R410a are super long lived and extremely toxic products that are toxic to produce. For all of the promotion of heat pump technology in thee trade, I don’t hear anyone address or emphasized how this is dealt with in the field. Sooner or later it will all end up in the atmosphere – maybe some of those things that should never be produced to begin with.

It’s not hard to imagine a future where our reckless use of these toxic greenhouse gases ultimately leads to our demise.

Thanks again to Allison for the forum.

The one downside of multiple outdoor units over a multi head unit is that all outdoor units keep their compressors warmed with a 150 watts or more of electricity when not actively heating or cooling, to keep.the refridgerant from entering the compressor oil and foaming. While it doesn’t sound like much, 150 watts times 24 hours is 3 killowatts per day. If your home needs 4 indoor units, having 4 outdoor units means 600 watts per hour just in standby.

Shannon, that’s an interesting point that’s worth noting. I will add that I have a Daikin multiport system that doesn’t use 150 watts on standby. I know because my Sense energy monitoring has an “always on” catch all category that’s usually hovering around 100 watts that includes 3 different standalone HEPA air filters that I run 24/7 at low – med speed plus any other phantom loads that I’ve mostly eliminated through turning off surge protectors. Point being, I would guess that mine uses somewhere in the neighborhood of 50 watts (if that) if what you’re saying is true…

That’s a good point Shannon B.

I recognize this as a classic design fork. Do we use several units in parallel or do we use a single large unit from which the service is distributed? I think the latter is often the first choice but often that doesn’t really stand to reason – especially as projects are scaled upward. I rhink tht there are natural economies of scale which favor of distributing single and central, variable capacity capacity equipment. Sometimes it’s a matter of inappropriately using power to implement distribution control logic – as in the case of zone pumps vs zone valves. In this case I think conserving and simplifying the use of refrigerant and minimizing leaks should be of paramount concern. So possibly the multi-unit approach is the simpler more durable one. Look what it does to the building though!

Dale, I know you like hydronic systems and I do too. This brings up still another advantage of Air-to-Water heat pumps. Heat pumps and AC systems have an expected life of about 15 years. When your Multi-split heat pump fails after 15 years, I don’t think any contractor will want to replace just the outdoor unit and reuse the indoor system. It becomes junk. But with an ATW heat pump, the refrigeration system is a discrete outdoor unit that can be easily replaced, while the indoor hydronic system has a much longer life that can outlast 2 or 3 or more outdoor units. Replacing a failed ATW outdoor heat pump unit is a simple process, so I don’t think the recommendation to use single zone heat pumps applies. There is also a backup resistance heater in the indoor buffer tank, so there should never be a loss of heating even it a new heat pump is not available immediately. In effect the ATW heat pump IS a single zone system. Its job is just to heat a tank of hot water.

Hello Gene,

You describe some of the advantages of using hydronics to create durable heating and cooling distribution systems. Yes, air to water heat pumps only see the buffer tank, the hydronic distribution system takes it from there to serve a variety of heat exchanger types, central air, fan coils, radiant panels etc.

The hot lash up is to use a Dedicated Outdoor Air System for Ventilation and De-humidification (DAOS) and then use relatively high temperature (66°f) radiant panels to absorb the sensible gains.

The de-humidification coil can be operated with chilled water from the air to water heat pump (38°f) to drop the moisture out of incoming ventilation air. Typically this drier air is then introduced to an ERV for fresh air distribution.

We are producing a new product here – insulation panels that fit our ThermoFin heat transfer plate – the system allows designers and installers to create practical radiant ceiling systems that can be used for heating or cooling.

Hi Dale, It sounds like you are working on commercial buildings with DOAS systems with energy recovery and chilled beams and radiant ceilings. I used to do that when I was working as a consulting engineer. It was the system that was more efficient than VAV systems we had been using and provided better ventilation. It’s interesting how residential systems in very low energy houses seem to be following a similar path: Air tight with ERVs and radiant floors or wall mounted fan coils for cooling and dehumidifying. I don’t hear of many homes using passive Valence heating and cooling distribution (Edwards Engineering), but it could happen. Not many folks are adding heating/cooling coils to their ERVs, but that would be easy with an air-to-water heat pump. I read that Mitsubishi is also selling a high-temperature ATW heat pump now in Europe, using Propane for the refrigerant. We need that in New England for all the older homes with hot water heat. The Air-to-Water heat pump is ideal for this, but also for new homes with low-temperature heat/cool terminals. 1. They are easier to maintain (remove outdoor unit and do the work in a warm shop), and 2. they have a backup resistance heater in the indoor buffer tank to keep warm if the heat pump fails. 3. Like all hydronic systems, they are easy to monitor with a temperature and pressure gauge. 4. Refrigerant volume is smaller and less likely to leak with no field-made joints. 5. From what I have seen, very-low GWP refrigerants are coming (propane and CO2) in order to reach the higher temperature needed in old homes. That’s good for the planet. 6. Since all the refrigerant is outdoors, they can safely use low GWP flammable refrigerants like propane. 7. The coming high temperature hydronic models that could replace a boiler and use the existing distribution system (plus a few AHUs for cooling), might lower the installed cost enough to drive wider adoption. 8. In addition, with a higher water temperature available, they can recover from substantial night setbacks in a short time and then revert to a lower temperature to maintain comfort with higher efficiency. The mini-splits can’t do that because the supply temperature is too low, and so their remote controls don’t include the setback feature. But setback is a way to reduce the total amount of energy you have to provide on an annual basis, so giving that up with a mini-split means you have to pay for more energy each year. 9. Heat pumps and AC systems have an expected life of about 15 years. When your Multi-split heat pump fails after 15 years, I don’t think any contractor will want to replace just the outdoor unit and reuse the indoor system. It becomes junk. With ATW heat pumps all of the indoor distribution and storage tanks are generic and completely reusable. You would just replace the outdoor unit as you would if your boiler failed. The rest of the system can be reused, saving money on initial installation and replacements. 10. Your plumber can install them just like a hot water boiler, so the shortage of refrigeration technicians would not hinder nationwide home electrification. The more I learn about Air-to-Water heat pumps, them more I think they are the ideal system for new and old homes. New ones would use low temperature heat distribution, but the coming high temperature models will work on older homes with baseboard or radiator heat.

Hello Gene,

Yes to everything in your post except that I mostly work with residential building. My specialty is hydronics and radiant panels. We manufacture extruded heat transfer plates that we use to create radiant panels including radiant floors and now ceilings. We were getting more interest in radiant ceiling cooling so we created a insulated panel product that accepts one of our extrusions which in turn accept PEX tubing. We can create radiant ceilings using products and methods similar to what we are used to using in radiant floors.

I’ve sold ERV’s for years. The DOAS ideas that are prevalent in commercial construction I learned from Robert Bean. With the ATW heat pump we have a way of providing both de-humidification and sensible panel cooling with a hydronic distribution system. One of the reasons I am lurking on Allison’s excellent website is learn more about moisture handling and other kinds of heat pumps. I think that hydronic distribution and ocontrol the doas / ATW / hydronic radiant panel cooling offer very useful features that address a lot of issues with air to air heat pump systems. These issues are well represented in this thread.

We are hoping to see Viessmann’s propane based ATW monobloc system sooner rather than later. Yes, they claim it can produce ~160°f water and propane only has a GWP of 3. I think that propane is a doable refrigerant where CO2 is problematic at best. Viessmann’s existing condensing gas boilers are capable of a 20% hydrogen mix. They have plans to increase this to 100% as they Germany’s hydrogen plan established. This is also a fuel that can be solar/wind produced, stored and used in existing infrastructure. Viessmann being Viessmann they also offer fuel cells off the shelf. We do hope to get their ATW heat pumps soon. Thanks for your interest and thanks to Allison for the forum.

My 1960’s 4,000sf ranch home is comfortable after doing many insulation and sealant upgrades over the decades. To get to the point my house has three std. air conditioners with propane furnaces. When one system fails, we have two other areas in the home to stay cool or warm as the case may be. My AC guy also believes minisplit units should be stand alone without any extra indoor units. One or two fully working systems out of three is better than none!

John Gwinn,

Well, the redundancy argument has it’s adherents. With my hydronic systems I beg to disagree. However, with refrigerant systems, I would agree with your “AC guy” – though the attitude speaks to the how reliable he thinks the equipment is. Much of this mechanical stuff seems pretty cheesy, i.e. not well built.

I had issues with my oil heated hydronic system multiple times. Everything fails eventually

You oiled fired hot water system is not the same animal as an air to water heat pump driving several independent zones of radiant floors. You don’t have to handle air to use heat pumps which are happier with the water backed heat exchanger and low temperature distribution system.

The economies of scale have it that as soon as you rack up several units in parallel then the pressure is on to make each one cheap so as to make the whole system affordable. It is possible with the system I described above to set up central high quality source equipment that serves distributed, automatically controlled heating zones.

Yeah I have one mini split one to one unit which does most of my cooling and heating. Especially in the winter I usually run that unit and leave the bedroom doors open more often than not. I kind of wish my bedrooms were set up that way but what are you going to do. Seeing that it’s my only heating source now that I got rid of oil I do need a unit in each room if it gets real cold so then I would have four outside units which would be a bit much.

Allison, you’ve also posted on how very tight, energy efficient building techniques, such as SIPS, can result in cooling efficiencies of ~1 ton per 1500 sqft. The smallest residential mini-split heat pump I’m aware of is the Mitsubishi 6K (e.g. 750 sqft assuming 1 ton per 1500 sqft). I’ve also seen a 4K designed for marine use. Given that most residential rooms are much smaller than even what a Mitsubishi 6K can handle, where’s the economic tradeoff between a 1 to 1 system this blog is proposing versus a low/mid static slim duct system? Especially given that, for Mitsubishi, you go from a 33 Seer rating with a 6K 1:1 system to a 19 Seer rating with a 9K slim duct?

Also, why isn’t VRF being offered in the residential market?