Air Sealing an Attic Access the Right Way

Attic access points can be a mind-blowing thermal liability. If you don’t believe me, open the pulldown stairs or scuttle hole and go into an attic on a cold day. Then turn around and look down through the hole. You’ll most likely feel a strong whoosh of warm air from the house hitting you in the face. That blast of expensive air being lost is courtesy of the stack effect. Air sealing an attic access is one critical part of reducing that thermal liability. The other critical part is insulating the attic access, which I’ll cover in a separate article.

Pulldown stairs

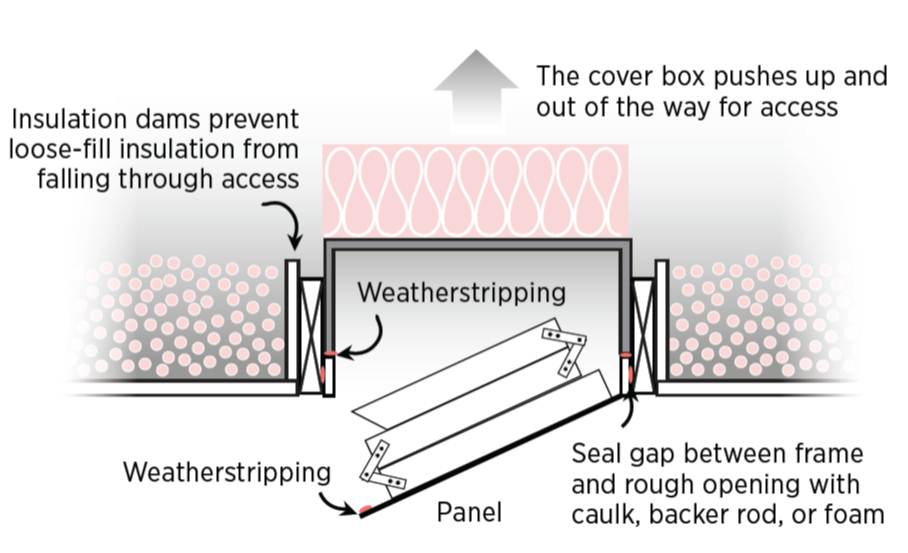

The Building America Solutions Center has a helpful guide on air sealing an attic access, and the image below comes from that site. (I’ve listed two more great resources at the bottom of the article.) Note the locations they indicate for sealing. They use the word weatherstripping, but it could also caulk, spray foam, or a gasket.

The best solution to that problem is to put some kind of cover above the pulldown stairs. The photo below shows one called the Attic Tent, which is one of many commercially available attic access covers. Tamarack has two types: the E-Z Hatch and the Battic Door.

In my contracting days, I installed a lot of these. They go in easily with staples and caulk, have a zipper around the edge, and provide a pretty airtight attic access. I also liked them because I could insulate an attic and use that cover to keep the cellulose dust out of the house. The biggest downside to the Attic Tent is that it’s only about R-6.6.

One popular method I’m not fond of is making a box out of rigid foam board to go over the opening. These are often too lightweight to provide a good seal around the edges. You can see a gap around the right side of the foam board box in the photo below. Another problem with this method is that people who use them set them aside and sometimes leave them there because they’re inconvenient.

Building a box out of wood can solve that problem. The photo below shows a well-built wooden box that’s air sealed and heavy enough to keep the top pressed firmly against the sides. I didn’t get a picture of it, but this one also had a latch to make it even more secure.

Scuttle hole

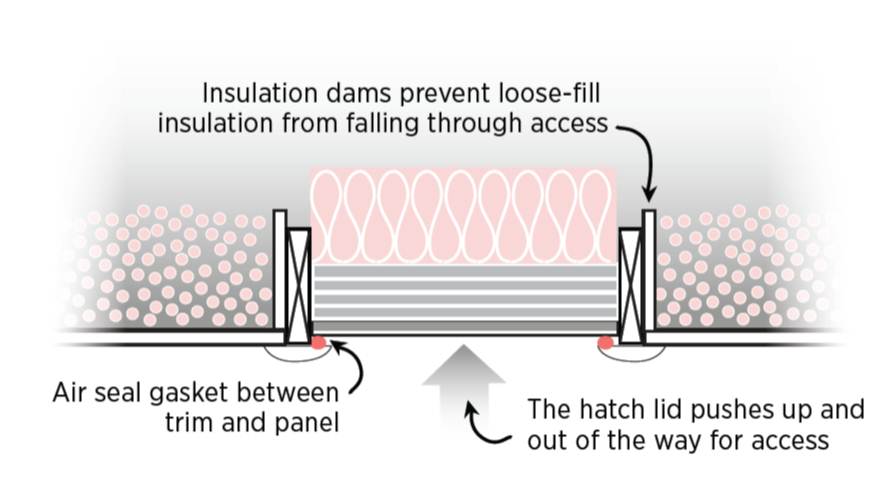

You air seal a scuttle hole the same way you do pulldown stairs and the comments I made above apply here as well. The Building America diagram below shows the details.

Kneewall door

Not all attic access points are in the ceiling. Some attic spaces are behind attic kneewalls. When you put a door in those kneewalls, it needs to be weatherstripped to make a good air seal. In the photo here, you can see the black weatherstripping around the full perimeter of the door.

Keys to air sealing any type of attic access

Here are some of the key points to consider when air sealing an attic access:

- Make sure you have a door or cover that can close securely with weatherstripping.

- If the main access doesn’t do that, install a secondary one. These are usually on the attic side, but I’ve also seen them on the conditioned space side.

- One way that helps make attic access points more airtight is to have some kind of latch to pull the cover tightly against the weatherstripping.

- Inspect the attic access carefully to find any air leakage pathways that need to be sealed. For house plans, use the pen test.

- Make it easy for occupants to use, including returning it to the sealed position.

Attics can be as cold as the outdoor air in winter and much hotter than outdoor air in summer. Everyone knows about insulating the attic, but many don’t understand how even a small part of the whole ceiling or kneewall can be a tremendous thermal liability. Air sealing an attic access properly is critical to having a robust air barrier.

Good Resources

Building America Solutions Center Air Sealing Attic Access – part of the US Dept. of Energy and one of many helpful pages on this site

Building Science Corporation Attic Air Sealing Guide & Details – Scroll down and look for the pdf download at bottom right.

Southface Air Barrier & Insulation Installation Component Guide – made for the Georgia energy code

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He also has a book on building science coming out in the summer of 2022. You can follow him on Twitter at @EnergyVanguard.

Related Articles

Attic Stairs – A Mind-Blowing Hole in Your Building Envelope

Heat Rises…and Falls — Stack Effect, Air Movement, & Heat Flow

Hidden Air Leakage Sites in Your Attic

Comments are moderated. Your comment will not appear below until approved.

This Post Has 20 Comments

Comments are closed.

Perhaps not necessary, but I added 2 latches to my scuttle hole to keep the cover extra snug against the weather stripping.

Jake, latches are a great idea for that very reason. If you rely only on the weight of the cover for your air seal, it won’t be as good. And without latches, it’s not hard for the cover to be skew-whiff and make an even worse seal.

Or you can insulate the entire attic using closed cell foam and solve the whole problem. Also, creates a really strong roof for survival against hurricanes, tornadoes, etc. Works great in coastal NC. Also helps keep humidity out.

Thomas: Yes, moving the air barrier to the roofline means that the attic is conditioned and you don’t need an airtight attic access. That’s what I’ve got in my house.

What do people with walk-up attics that are just used for storage usually do (if anything?) I have a walk up attic in a four-square style house. I was debating foaming the rafters and conditioning the attic vs building up the attic floor with cross-joists and adding cellulose and creating a small storage area with some plywood on top of the cross-joists. I ran across this article by a company in NYS that says you can foam the rafters or seal off the walk-up stairs with a hatch. What do you think of the hatch idea:

Options:

https://www.halcoenergy.com/insulation/technical-papers/31084-different-methods-to-treating-a-walk-up-attic.html

This link has the attic hatch addition idea explanation with photos:

https://www.halcoenergy.com/insulation/photo-gallery/24349-album-treating-a-walk-up-attic-in-rochester-ny.html

aaron: Yes, both of those methods work. Hal Smith knows his stuff, and his company, Halco, is well respected for their home performance work.

How would you do a whole house fan? Thanks

thom: Well, here in the Southeast, I’d probably rip it out and install drywall over the hole. If you want to use a whole-house fan, it’s still best to replace an old one with a new, more efficient model. Tamarack sells some nice whole-house fans that seal well when not in use.

https://www.tamtech.com/shop/whole-house-fans/

Thanks

Don’t forget your article on “Lumpy Insulation”. That was an eye opener for me.

On one of my plug access doors, I cut nails into the edge to use as pins that go into holes in the frame on one edge. I weather stripped the opening and put a hook latch on the opposite edge with a handle to pull the cover tight until it latched.

David: I’ve covered that same issue in other articles, too. The most recent one is from last summer:

Does Poor Installation of Insulation Hurt R-Value?

Great job on your attic hatch. The latch is an important part!

Great – another weekend shot fixing a problem I didn’t know I had 🤣

Articles like these have potential to create $avings equal to the GDP of a small country, and delay the breaking off of an ice shelf in Antarctica by a few years!

We’ve done most of the above methods, my favorite is built up sides of the access opening, be it a scuttle hole or a pull-down, which allows for a flat lid on top: a favorite number of layers of XPS sandwiched between two pieces of 5/8 or 3/4″ plywood (always some subfloor remnants laying around). Has enough weight to keep the weatherstripping pressed, you can add a simple handle and a couple hooks to keep it from popping off in a wind storm when someone opens a door or a window below.

The exposed XPS or similar foam boards serving as access covers technically are not up to fire code. You would want your ignition barrier to be continuous across the ceiling.

Paul: One way to solve the fire code issue is to use Dow Thermax, which is a foil-faced polyisocyanurate and has the approval to be left exposed.

Agreed on Thermax, but ouch, the price! We recently needed two sheets to insulate utility doors and it was almost $130 for two 1.5″ 4×8 sheets!

Holy moly! It’s gone up a lot since last time I bought some. I believe it used to be about $15 a sheet.

This is off topic but still in the attic. I recently had my roof shingles replaced. After they got done I noticed when they put the ridge vents on (It originally had the round roof vents) they didn’t apparently have any foresight to cut back the plywood along the ridge as required by the vent maker to allow proper spacing for air flow. So now I’m going to have to have them come back and remedy they’re screw up. Just one more thing to look out for when you have your roof replaced.

Skuttle-Tight makes a skuttle hatch that’s an interesting alternative to site-built.

Not sure about price, but seems like a decent product on paper. It has a drywall taping flange, so no need to make a picture frame on the ceiling out of door casing.

I’m planning on trying out the sidewall version at some point in the future (no overhead attic access), so if anyone has any product feedback I’m all ears…

We have a 1920s home in Charleston that has its original pulldown, Bessler Hidden Stairs going into the attic. We know we need to insulate that attic access, but can’t figure out the best way to do it since the stairs don’t fold. Do you have any tips? (or should we just replace the attic stairs with a folding ladder so that we can insulate the access as you detailed?) Thanks!

Great article. How does an average homeowner figure out what kind of rigid foam board to buy and how many of them add up to R-38 to match the rest of my attic insulation and what kind of glue to use to stick them on top of each other and to the drywall or wood? Every time I’ve walked into a home improvement store trying to figure out which “XPS” to buy for this little project, I got dizzy.

Related DIY question: “air seal gaskets” and “weatherstripping” come in several forms. Rubber, silicone, polyethylene, foam, thicker foam… Which one works best for this use case?