Can You Replace an Air Conditioner With a Same-Size Heat Pump?

I recently got a couple of questions from someone who’s interested in changing out his air conditioner and furnace with a heat pump. With the Inflation Reduction Act and all the talk of electrification, the question is becoming more common. Let’s talk about it.

The questions

Here are the questions I received:

If I replace a 5 ton AC + 100,000 BTU/hr furnace with a 5 ton heat pump:

i) Will my home heat up more slowly?

ii) Is the total heat generated create sufficient heat to the desired temperature of 70 degrees (say from 45 degrees to 70 degrees)

I’m sure many homeowners have the same or similar questions, about this kind of heating and cooling system replacement. The answer to the first question is yes. A 5 ton heat pump has a capacity of 60,000 BTU/hr, so it will heat the home up more slowly. Let’s focus on the second question, though.

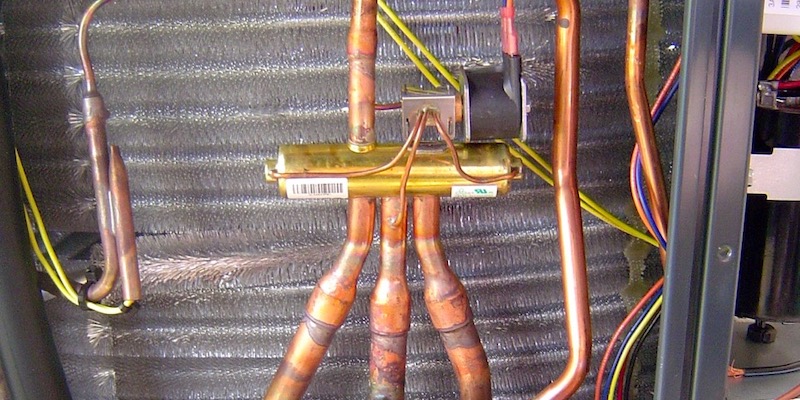

With an AC and furnace, you’re heating from the furnace, but a heat pump is more like an air conditioner. In fact, a heat pump is really an air conditioner that can operate in both directions. In air conditioning mode, it pumps heat from indoors to outdoors. In heating mode, it pumps heat from outdoors to indoors. The reversing valve (shown above) is the component that makes that happen. So how do you figure out if you can replace a 5 ton air conditioner with a 5 ton heat pump?

One way to approach it

The person asking the questions above knew that the heating capacity of a 5 ton heat pump doesn’t match that of a 100,000 BTU per hour furnace. He did the calculation to come up with a (nominal) heating capacity of 60,000 BTU/hr for the heat pump and then asked if he should add 5 kilowatts (kW) of electric resistance heat strips for more capacity.

That still wouldn’t get the system to match the 100,000 BTU/hr furnace, so then he asked about the possibility of going with a dual fuel system. Instead of going heat pump only, a dual fuel system pairs a heat pump with a furnace. That system uses the heat pump down to a certain outdoor temperature. Then it switches to the furnace. The heat pump can be set to switch to the furnace at whatever temperature that makes the most sense.

The answer

Now, many of you reading this already know why that line of thought is taking us down the wrong road. There’s an assumption built into that is not justified. Trying to get the heating capacity of the new heating system (heat pump or dual fuel) to match heating capacity of the existing system assumes that the existing system is sized properly. And that’s almost always not true.

So the first thing to do if you want to change out an air conditioner and furnace with a heat pump is to find out what the heating load is. If the existing system still works properly, one way to do this is to see how long it runs when the outdoor temperature is close to your local outdoor design temperature.

Here in Atlanta, for example, our winter design temperature is 23 °F. If a 100,000 BTU/hr furnace runs for 30 minutes an hour when the outdoor temperature is about 23 °F, the heating load is about half the capacity of the furnace. That means the heating load in this case would be about 50,000 BTU/hr, so you could put in a 5 ton (60,000 BTU/hr) heat pump and probably be OK.

Keep in mind this method is an approximation. The result you get will depend not only on the outdoor temperature when you time the furnace operation, but also what the outdoor temperature was before you started timing. If it had been 10 °F for three days and then warmed up to 23 °F, you’ll get one answer (more heating load). If it had been 40 °F for a week and then dropped to 23 °F over a few hours, you’ll get a different answer (less heating load).

Load calculation and equipment selection

Even accounting for the previous weather, though, is a simplification. Better would be to have long-term runtime data. Few people except energy and HVAC geeks like the people I hang out with have those data. What you can do instead is hire someone to do a heating and cooling load calculation. They’ll need a lot of information about the house for the results to be accurate. But with an experienced HVAC designer, you’ll also get a lot of useful information.

And the process includes more than just finding the heating and cooling loads. You really should have them do the equipment selection process as well. Why? Well, especially if you’re going with a heat pump, you’ll need to know that the system can meet the heating load at the design conditions. And if it can’t, you’ll need some kind of auxiliary heat.

I’ve written about these topics in many ways here in this blog, so if you follow the links in this article and below, you can find out a lot more about this topic. But to go back to the question at hand, when replacing a furnace with a heat pump, don’t assume your current system is sized correctly.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He also has written a book on building science. You can follow him on Twitter at @EnergyVanguard.

Related Articles

How the Heck Does a Heat Pump Get Heat from Cold?!

How to Read Manual J Load Calculation Reports

Heat Pumps, Auxiliary Heat, and Resilience

The 3 Types of Heat From Heat Pumps

Comments are moderated. Your comment will not appear below until approved.

This Post Has 38 Comments

Comments are closed.

The revised Manual S Normative section is out for public review. Everyone should check it out. Especially section N2 on sizing limits. There are some interesting new twists on heat pump sizing. There are three approaches:

1. Standard – size to cooling load and make up difference with strips.

2. Dry climate – allows some additional AC oversizing and therefore less strip heat.

3. Advanced – provides criteria for sizing variable speed equipment to satisfy all of the heating load.

Obviously, cooling load calcs are needed too!

There is a fourth sizing method for variable speed heat pumps that I forgot to mention.

The furnace seems to be greatly oversized for this application unless it serves a massive house. Looks to me like this furnace was chosen for the air flow requirement for a 5ton AC unit, not the actual heat loss of the home. In my region, we have small AC loads and large heat loss. From some quick assessment it looks like a 5 ton HP would probably work decently. Always best to get a heat gain/heat loss done.

Now, would it be a variable speed HP or a single or two stage system proposed here. Could make some difference!

Russ, Could you provide a link? A search for Manual S Normative section didn’t produce any results. Thanks

Looks like you have to email a request to get a copy. Here is the press release I got:

For Immediate Release

November 25, 2022

Contact: Melissa Broadus

703-824-8842

melissa.broadus@acca.org

ACCA’s Manual S® Is Out for ANSI Public Review

Alexandria, VA (November 25, 2022) −The Air Conditioning Contractors of America Educational Institute (ACCA-EI) Standards Task Team (STT) announces an American National Standards Institute (ANSI) public review period for the “BSR/ACCA 3 Manual S – 202x, Residential Equipment Selection” as a revised industry standard. The 45-day ANSI public review period will start on November 25, 2022, with a comment deadline of January 9, 2023. The proposed standard is a revision of ANSI/ACCA 3 Manual S – 2014.

This revised standard provides procedures for selecting and sizing residential heating, cooling, dehumidification, and humidification equipment. The standard is divided into two parts – a “normative” portion that details the selection/sizing criteria and an “informative” portion that provides discussion, guidance, and example problems related to procedure intent and use. The public review draft only contains proposed revisions to the normative sections, which are Section N1 – Definitions and General Requirements; Section N2 – Equipment Size Limits; and Section N3 – OEM Verification Path.

A red-line review draft of the above proposed revisions can be obtained by sending a request to standards-sec@acca.org. Comments should be submitted to same address.

A great way to get an idea as to the capacity vs. load of an existing furnace is to have a “smart” thermostat installed for a season prior to making the change. Most of them will give you a graphic illustration of the furnace “on times”, showing each heating and cooling cycle. At or close to outdoor design temperatures you will most likely see that the “on” times are equal to or even shorter than the “off” times, indicating that the appliance is indeed over-sized. It is still best to get proper heat loss/heat gain calculations done, but the visual proof from a smart stat is reassuring to see before you take the plunge.

Roy, do you know of any that overlay run times with outdoor temperature? Theoretically, a properly sized system will run almost continuously when the outdoor temp is at or above the outdoor design temp.

Hi Russ, I have an Ecobee stat that displays a timeline graphic. It includes equipment “on/off time” at the same time as outdoor temperature and humidity and indoor temperature and humidity. For HVAC engineer geeks like me, that tells the whole story. For most folks to interpret the information, a good book like “A house has to breathe …..” will be handy in trying to parse through the data to figure out what it all means. Further posts in this topic have identified some other really important points such as taking into account the energy needed to recover from set-back/unoccupied events. If this was easy – we wouldn’t be talking about it. Details, details, details.

Keeping in mind, you’ll need to move more air through the system with a heat pump than a furnace

I enjoy your articles. I find them helpful and instructive. We almost never run into a comfort system that was designed. We find homes with double the needed capacity and worse.

But I think now that if a load calc happened to land right on the Btus of a piece of equipment, I might be tempted to jump to the next larger model.

I recently bought a house that has a separate space with a heat pump. While our weather has been fairly cold this year, our design temperature is 9 degrees F. We’ve spent little or no time as cold as that. But if I let the indoor temperature drop to 60 degrees overnight, it’s next to impossible to get it back to 70 before it’s time to set back again. I’ve run it for eight hours without getting up to 70. But when I leave it at 70, it maintains that temperature once it gets there. While not a scientific test, the day and night time temperatures were similar during this time.

I’m sure my system was never designed. The house was a flip and I suspect the system was put in by the lowest bidder. I will be performing a load calc and will probably replace the current system (a 30,000 Btu Mitsubishi HyperHeat system serving about 1,000 square feet), although I am scheduling one of my technicians to check out the operation of the system to make sure it’s performing as advertised.

So while my system appears to be capable of producing adequate heat for maintaining temperature, it lacks when it comes to recovery after setback.

10 degrees is a really big setback! There are some studies going on looking into setbacks and heat pumps. It may turn out that you shouldn’t use setback at all on a heat pumps.

I’ve wondered about the size of the setback and how much energy is saved. One can search for research only to be inundated with opinion. Of course, I developed my setback mentality while living with massively oversized gas-fired equipment that had little trouble making up ten degrees. Even the system for the main house (that will also be replaced) recovers ten degrees in very short order.

I agree with Russ King. Our setback is 5 degrees and it takes our 80% furnace a couple of hours to manage to get back to 70. This is in Denver in a 1974 house. Wanting to get the attic sealed and R-60 insulation put in during 2023. Then change out to a heat pump. With a heat pump from what I understand I will probably only do a 3 degree setback. But I am hoping with the sealing and insulation it will be able to hold temperature a lot better. Currently with the R-20ish even the with sub-zero F temps recently it didn’t reach the 5 degree setback until 5am or so starting at 11:45pm.

Not making light of data and/or manual JDS calcs, I do subscribe to setbacks of 12 degrees in heat pump only commercial spaces of 3-7 ton units and they reach setpoints in 10-15 minutes.

With respect to the original question on heat pumps in residential applications, I believe that 2 stage heat pumps may be an overlooked solution.

Randy: Multi-stage or variable capacity equipment is the way to go!

As a decades long heat pump user, I find its bette to set it and forget it in colder than 40f weather. No set backs. 25f ambient with 75f setpoint means a 50 degree delta t. In cooling. 95f ambient to 75f is only a 20 degree delta t. Huge difference. Given electric backup strips are three times more expensive to operate, keeping the house at a constant temp is usually cheaper than using strips to help recover a setback. Finally have enough strips to do the job, usually 15k for a 5 ton ac.

Look, here in Southern California electrification is pushed and incentivised. I do alot of system design. I also do in home sales as well as commercial proposals and project management.

I agree that a 100,000 btu furnace may be oversized. Definitely in Southern California. The efficiency of the unit matters such as 80%, 95% ETC. Where your btu output on said furnace would be the percentage of that

Other contractors in my area have had problems when swapping to heat pumps for these issues which are universal in the states: Ductwork and insulation. The homeowner complaints of high utility bills and taking very long to heat is the main issues.

Our number one item on a heat pump conversion is ductwork and insulation.

Have the right conversation.

A gas furnace requires less cfm to impact the air than cooling. With a heat pump you are using cooling cfms for heating. The temperature of the air is also not going to be as high with a heat pump.

Proper duct sizing and insulation should be the go to when deciding if the fit is correct as well if the homeowner will pursue implementing those recommendations if there system is inadequate.

Also, multi stage equipment and variable speed airflow need to be talked about. The least is a variable speed blower. That blower allows you to have proper cfm delivery, and adjustment to ducting afterward can be made on a prescription based approach.

I also recommend installing a ducted minisplit or multiple head system. Reason being is they are more targeted conditioning as well as greater design temps from 120 degrees down to 12. Traditional non variable speed heat pumps will drop capacity as it gets closer to 32 degrees and above the design temp for your area.

The technology though is getting there where Mitsubishi and Daikin wont habe that edge in design temp.

I didn’t understand how the past temperatures affected the sizing. Would the heat capacity not just be related to the temperature of the air at the present time?

Barry Westbrook

When his indoor set temp changes from 60 to 70 (usually early in the morning when it is really cold) it takes a lot more capacity to change the indoor temp in a reasonable amount of time than to maintain a constant temperature at either 60 or 70. If it can barely hold 70 deg, it will be almost asymptotic as it approaches 70. The closer it gets to 70, the longer it takes to change the temp.

Here’s another interesting observation. My floors are warmer since setting a constant 70F. I guess that’s to be expected, but the thought hadn’t occurred to me. I have ceiling cassettes, and I’m typically barefoot in the morning. On about the second day of constant temperature, I walked into the space and noticed the floor wasn’t nearly so cold. That makes the room feel warmer and might be worth pointing out to clients who switch to heat pumps. Even if one isn’t barefoot, the room will feel warmer if the floor is warmer.

This seems over complicated to me, on a heat pump true capacity is going to be determined by air flow across the coil. The duct system, square footage and location of your house will determine the the maximum allowable capacity. You can’t put a five ton in a thousand foot house or it’ll be very drafty, you’ll also have ducts everywhere. Capacity is also limited by outdoor ambient temperature, the idea you need more capacity as it gets colder outside is not going to work on a heat pump, if oversized it creates a high humidity disaster in cool mode due to reduced run time. At some point you have to consider dual fuel or just relying on the element. If your system is sized correctly in cool mode then it’s right in heat mode, if it’s not getting it done maybe you need to address heat loss. After over 20 years in the industry most units need to be downsized not upsized. I downsize a few change outs a year for humidity control, extremely rare to increase the size of a unit unless additional space has been added. The simple answer to the original question is yes, the more complicated answers are going to hardly apply to anybody.

Yes you can but should have a proper heatload done because things change proper sizing is very important

If the original unit was sized properly via load calc then the replacement can be similar size. If not, load calc should be done. The dual fuel is the best of both worlds in cold climate- you can properly size the heat pump for AC and then have the furnace for cold snaps.

Longer run times= more comfortable house

Bingo! No matter what the heat source – this is true. Deep turn-down modulation of heat output can help with oversized equipment or during mild weather while still allowing for rapid heat-up from set-back recovery. Back-up / supplemental electric resistance heat (strip elements) for heat pumps can give you the needed boost when required.

It would be nice if smart thermostats had adjustable cycle off/on intervals. We use Sensi wish we generally like, but the mode with the longest delay between cycle off/on is less than 1 degree F. I’d prefer something around 2 degrees.

Yes it would be nice to be able to tweak the operating temperature differential among other settings but the control manufacturers generally do not think the average consumer is clever enough to figure these things out. To their credit, they often have a point – unfettered adjustment of many settings can spell trouble for equipment so they try to come up with a reasonable middle ground based on equipment selection. Have a close look at user manuals, there can be important details in them about adjustments. Try and get the “Contractor’s” I&O instructions which may contain “secret” access codes to get you deeper into the more advanced settings. If you are persistent and lucky, you may find someone at the “factory” who can show you some tricks, but that kind of access is increasingly rare these days. Any modification of settings beyond the normal will require careful thought, and always know how to restore back to factory settings if things get wobbly.

My company pairs new heat pump replacements with beefing up insulation and doing a duct (if ducted) and air leakage test by pressurizing the system or the house. Give you a good idea of ACH and heat loss when coupled with tracking on off periods thru the year and load calculations. And typically furnaces are oversized for heat loss and to avoid call backs. An oversized system isn’t a problem in most homeowners’ eyes other than utility costs. Most heat pumps are recommended to be left on to maintain temp not turned on and off willy nilly because of their slow output.

PS I’m a pixie wrangler not an air mover 😉

I’m an HVAC contractor in Los Angeles. Beyond the issue of capacity, remember that in case of power failure, a furnace can be run of a small generator. 110V 20AMP. HeatPump will require MUCH larger capacity generator. In this case 5Ton system will require 220V 50AMP for the condenser and 220V 20AMP for the AHU.

Does it worth the risk that an ice storm will leave you without heat?

In addition to utilizing guidelines to selecting the heat pump, is to also make sure the contractor fully explains the extended run cycles, which would help ensure that the consumer understands and has reasonable expectations.

This is one of the reasons I like inverter-driven (aka, variable speed) systems. Some of these systems have an extended heating (sometimes called boost or hyper-heat) mode, whereby the compressor is over-sped. This generates more heat in a few different ways:

• Additional refrigerant compression for an increase of the refrigeration effect (facilitating more absorption from the heat source).

• More heat of compression (due to additional mechanical friction within the compressor and additional refrigerant friction from compression).

• Additional motor heat (the motor heat output for even a slight overspeed causes a great amount of additional refrigerant heating, since virtually all refrigeration compressor motors are cooled by the suction gas.

Even though I’ve been in the HVAC field for 40 years and have known the advantages to having a heat pump…I only recently lived in a house with a heat pump.

One feature I really recommend is to have a thermostat, with an “intelligent” recovery setting, which gauges the time it will take to recover to the desired space temperature (assuming you use the setback settings).

Why would you change air con to heat pump if you can run 10x cheaper Aircon unit as a heat pump simply by changing internal unit with plate heat exchanger or make your own pipe in a pipe heat exchanger which will be connected to a heat buffer. Easy diy and no thieving companies involved as this is super easy.

M: Let’s start with the fact that it would almost certainly void the warranty on the air conditioner. If that’s not an issue, it seems that this “easy diy” modification would have to involve messing with the refrigerant, which isn’t legal if you don’t have the EPA 608 certification. That would certainly take it out of “easy diy” territory.

If this “pipe in a pipe heat exchanger which will be connected to a heat buffer” doesn’t require changing the refrigerant flows, you’re gonna have to explain to us how a system that moves heat from indoors to outdoors can do the opposite with this “easy diy” hack.

Extremely bad idea. Reversing valve, lots of copper plumbing, evpansion valve, defrost circuit board, defrost sensor. Most do it yourself as couldn’t do it because of the thousands of dollars of tools one would also need. But still the biggest reason not to do it….not engineered for efficiency.

I know many certified refrigeration techs who would not touch this with a 10 meter pole (Canadian eh). I would not want to live next door with a DIY modified unit next to my house when it goes BANG – SSSSSSSSSSSSSSS! Right next to my HRV fresh air intake. You would be hearing from my Brother, who is a litigation lawyer.

I think someone has been reading how an advanced technology low ambient heat pump adds a plate heat exchanger to the outside unit to provide vapor injection to the compressor. But these advanced heat pumps, pioneered by Mitsubishi as “hyper heat” models, still have reversing valves, accumulators, electronic expansion valves and the ability to drive a variable speed compressor overspeed to maintain nominal btu output at low ambients. Plus a gas bypass circuit to defrost the outdoor coil. An amazing piece of value engineering for the residential and light commercial market, available from Mitsubishi for decades. However their patents may have expired. Today the advanced diyer can buy similar technology from several Chinese suppliers for 1/3 to 1/2 of the cost of a Mitsubishi hyper heat installed. A Chinese low ambient heat pump without the reliability and assurance of quality but anyone who could add a heat exchanger to an existing ac could do a complete install easily. And possibly have something that would work at the end of the day.

I am interested to understand more about M’s comment: “Why would you change air con to heat pump if you can run 10x cheaper Aircon unit as a heat pump simply by changing internal unit with plate heat exchanger or make your own pipe in a pipe heat exchanger which will be connected to a heat buffer. Easy diy and no thieving companies involved as this is super easy.”

It’s fascinating how the conversation around HVAC systems is evolving with the Inflation Reduction Act and the push for electrification. Your blog post highlights some crucial considerations for homeowners looking to replace their air conditioner and furnace with a heat pump. The distinction between heating capacity and the assumption about existing system sizing is particularly enlightening. Your method of gauging the heating load by observing the furnace’s runtime during the local outdoor design temperature is a practical approach, though load calculations and professional HVAC input seem essential for accurate results. Embracing a holistic perspective, including equipment selection and potential auxiliary heat needs, is indeed pivotal for a successful transition.

Howdy neighbor (I am on Vancouver Island).

By far, the most accurate way to determine actual heat load is to use data from the run-times of existing heating / cooling equipment vs. outdoor temperature and other significant environmental factors such as wind speed. But – – the devil is in the details. Occupancy and usage patterns can skew the numbers all over the place. The best approach would be to use consumption data from many, many sources to even out the peaks and valleys of individual results. As much as I dislike the AI will solve everything attitude – I can see where accurate data fed into a database might allow AI to come up with meaningful conclusions AND keep a running tab as this all develops.

We do live in interesting times.