Is Wind Washing Reducing Your Insulation R-Value?

You’d think that after more than 12 years and a thousand-plus articles, I’d have mentioned all the major building science terms by now. Yet, here we are. I just did a search of all the articles in this blog and found out that I haven’t used the term “wind washing” at all. Not once! So let’s fix that today.

What is wind washing?

Wind washing is the effect of wind causing air to flow through or around air permeable insulation, thereby reducing its R-value. One of the most common ways this occurs is when you want outdoor air to come into an attic or a cathedral ceiling for venting. If the pathways for air flow aren’t defined precisely, wind washing is often the result.

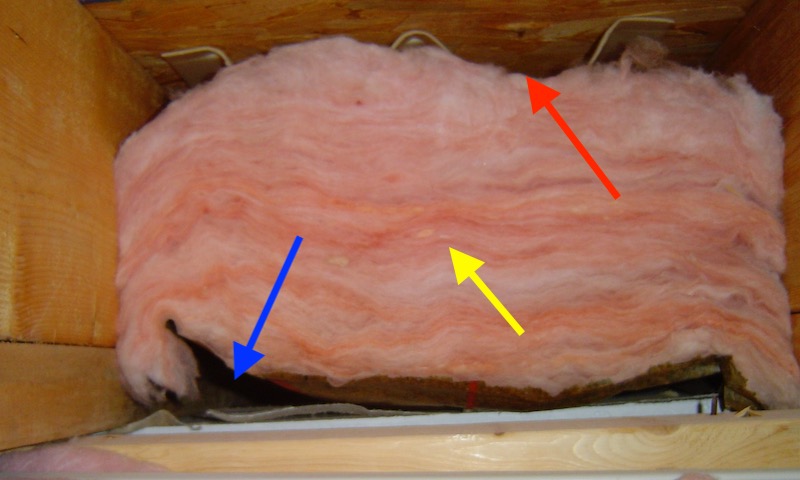

The lead photo above and the one just below show fiberglass batt insulation in cathedral ceilings. Both have baffles installed above the insulation, where the air is supposed to go. But guess what. Air is the honey badger of building science. It don’t care what you want it to do. It’s gonna do what it wants.

See those arrows below? The red arrow is where the architect and the the builder told the air to go. And the air says, yeah, I’ll take that path. But I’ll also go down below the insulation, in the gap where that blue arrow is. In the photo above, the insulation has a huge gap beneath, allowing for easy movement of a lot of air. And because fiberglass insulation is mostly air anyway, it’s going right through the middle, too, where the yellow arrow points.

How well do you think that insulation works with all that air passing beneath it and through it?

Wind washing and blown insulation

Perhaps the most well known example of wind washing is when you have blown insulation in a vented attic. If the pathways for air flow are defined poorly, as above, the wind blowing into the attic can blow that insulation around. The photo below shows one example. But it can be far worse than that, too. Sometimes you’ll see large bare spots near the eaves as all or most of the insulation gets blown inward.

How bad can it be?

Wind washing can cause more than high energy bills, though. A cold wind blowing across your ceiling can change the mean radiant temperature you feel inside the house and make you very uncomfortable. And that’s true even when your heating system is keeping the air temperature at what should be comfortable.

But if the surfaces get cold enough, you might even get condensation on your walls and ceiling. And if it’s really bad, as was the case in this Kansas City house a few years ago (photo below), the condensation turns to ice. Yeah, you’ve got a serious wind washing problem if it gets that bad.

How do you stop it?

For cathedral ceilings and attics, the solution involves being really strict about telling the air where it can and cannot go. The cardboard baffles in the photo below are stapled properly to the trusses to allow insulation to go over the top plates in that wall. The air from the soffit vents pretty much has only one way to go: above that angled piece of cardboard. The top edge of that cardboard needs to be at least 4 inches above the top of the insulation. (Whether or not cardboard is an appropriate material for these baffles is a whole other issue. I see it a lot here in the Southeast, though.)

The next photo shows a different way of defining those air channels. The builder first stapled up the purple foam baffles for attic venting air. Then they used pieces of blue foam board cut to fill the space above the outside of the top plates in the wall. You can see that they also caulked around the edges of that blue foam board. The air in this case has only one pathway, and that’s the one where you want it to go.

Both of the photos above are from Habitat for Humanity projects. The first one is from Nashville, Tennessee and the second from Mount Airy, North Carolina. What I saw at a production builder’s new home site in Atlanta last year, however, wasn’t nearly as well executed as what these volunteers did.

With new homes, this should be pretty easy because you’ve got access to those areas. In existing homes, it’s a whole different story. One of the best ways to define the air flow pathways is when you’re getting a new roof. At that time, you can have the roof decking pulled up at the eaves and get easy access to the eaves. (Be sure to air seal the top plates while you’re in there!) If you’re doing it with the roof in place, you might need to find some hobbits to crawl in there.

The Building America Solutions Center page on wind washing and how to fix it in both new and existing homes is a great resource if you’re looking to go deeper.

But wait…there’s more!

Wind washing isn’t just a ceiling thing. Anywhere in a building that wind can get in and move through or near air permeable insulation, you can get a reduction in R-value. Another particularly susceptible area is cantilevered floors. Without a good air barrier, wind can get in and blow through or around the insulation. The overall solution for all areas affected by wind washing is to define clearly—with actual materials, not just arrows on drawings—where air is allowed to go and where it’s not. This means having materials and assemblies that make up a proper air barrier and venting pathways.

Hat tips: Thanks to Lloyd Alter for writing a nice article on thermal bypasses last week and mentioning wind washing. And thanks to Mark Siddall for writing an excellent 70 page paper titled Thermal bypass risks: A technical review, which caught Lloyd’s attention and now has mine.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He also has written a book on building science. You can follow him on Twitter at @EnergyVanguard.

Related Articles

The Low Spark of Raised-Heel Trusses

Attic Stairs – A Mind-Blowing Hole in Your Building Envelope

Building Enclosures Have Improved More Than Ducts

Spray Foam Insulation at the Edge – A Forensic Analysis

Comments are moderated. Your comment will not appear below until approved.

This Post Has 29 Comments

Comments are closed.

When my house was under construction, the insulator did know about wind washing. He just wanted to put up netting at the ends to catch the blown insulation. To make sure it was done right, I put foam board at the outside edge and foamed the edges in. Worked great !

Norman: Good for you! If your insulator thought netting would help with wind washing he/she didn’t really understand wind washing.

I have seen the effect of wind wash in the new built homes i work in. Blown in insulation was installed prior to having soffit installed, you end up with a pile of blown in insulation in the center of your attic and nothing at the rafter tails. #HEATLOSS

We have a bunch of odd wind washing in our house. In one case if the wind blows hard enough in the right direction the linoleum in the kitchen with fill up like a ballon to the seam that’s glued down. It will get up to 4” tall. I’ve tried all kinds of caulking and foam sealants and can’t find the spot. It only happens every 3 or 4 years so I never know if it’s fixed until it happens again.

David: I’ve had the flooring blow up on me a couple of times but only during blower door tests. (It’s not very windy here in Georgia.) Here’s an article with a photo I wrote about the time it happened with the temporary plastic put down to protect the finished floor from damage in a new house:

https://www.energyvanguard.com/blog/A-Fun-Visualization-of-Air-Leakage-During-a-Blower-Door-Test

So if you don’t want to wait until the next big wind, just find someone with a blower door to help you out with an artificial wind.

Thanks, I’m replacing the entire system in a few weeks. I’m having a full test after it’s completed including a blower door test. We will see if I can finally fix that hidden leak. Insisting on the best practices if learned hear and with the building sciences corp blog, I ended up disqualifying over 50% of the proposals and an additional 34% recalls their bids. Because of the common expected standards explained here were to burdensome or beyond the contractors comprehension. Is a sad commentary on the state of the industry that they can’t, won’t, or doubt know how to follow current standards.

In the top of my garage I used 1 inch spacers for air circulation and cut 1 inch x2 ftx 8 ft styrfoam with a reflective side and put it between the trusses then sprayfoamed all edges. Then rock wool insulation bats over that. Was a lot of work but glad i did it. Toasty warm and no drafts.

Just another reason I use closed cell foam sprayed on the underside of the roof decking. The foam company is first in the structure as soon as the roof is dried in. That gives them full access to all the nooks and crannies without having to crawl around heating ducts, etc. We always blow under 1 ACH50. We also “cheat” by using monolithic concrete insulated wall systems. The UI on these walls is ridiculously low.

Thomas: That’s a great way to eliminate wind washing. Nice work!

Allison, thank you, probably millions of homeowners in this country lose their hard-earned money through their poorly insulated ceilings.

I’ve always wondered, we devise these “organic”, easy solutions, like the cardboard wind baffles. Will they last? Guilty as charged, I installed plenty myself.

On fibrous insulation layers (batts, blown-in), your article from 2019, https://www.energyvanguard.com/blog/does-fiberglass-attic-insulation-really-lose-r-value/ sheds some light on the convection problem within loose fibers. But now you’re saying that air will go through the middle of the fiberglass batt, because it’s mostly air. If we subject it to a stream of air at certain minimum velocity, sure, it will go through the batt fibers, but how far into them? In ideal world, all 6 sides of fibrous material would be blocked with an air-tight barrier, or at least 5 sides in case of the blown-in horizontal attic layer. The point is to not create voids during installation, and to not create opportunities for wind to create its own voids later on, in vented assemblies.

Paul: Yeah, cardboard wouldn’t be my first choice, especially in any area where wildfires occur. Aside from the durability and flammability questions, though, I never see these baffles sealed at the edges. The installers just staple them up and move on.

Fiberglass is used for filters so air can go all the way through them. In the case of unintentional air flow, as we’re talking about here, it also can go all the way through. In those first two photos, the air has easier pathways above and below, but without blocking some air will also go right through.

Think of a window that has fiberglass chinked in the gap between the wall framing and the window. If you’ve ever opened up a wall and looked at that fiberglass, you’ll usually see a lot of dirt in the fiberglass because of all the air flow right through it. It all depends on the pressure differences and pathways.

Ah, yes, those little fiberglass “filters”, have seen plenty of them.

In General, fibrous insulation should never be used as an air barrier. In particular, for vented assemblies, rafter or truss bays should be blocked and air sealed above the top plate, before stuffing a batt in the space. Ideally, the batts should touch at least all surfaces on the conditioned side of the assembly.

Goal: to eliminate pressure-driven air movement through insulation, and to reduce convective losses.

For a builder, those nooks and crannies in the remote and unreachable edges of the attic are true conscience checks. Nobody will ever see them, not even during most remodeling. How tempting to go easy on yourself…

And forget about the kraft-faced batts. They only introduce confusion: https://www.greenbuildingadvisor.com/article/should-the-paper-facing-of-batt-insulation-face-the-inside-or-outside

What they also introduce is small convective currents in the spaces trapped between paper and whatever the other surface is: back side of sheathing or sheetrock. Those can add to the total heat energy flow through the assembly. Just let the fibers touch the backside of sheathing and sheetrock, and be happy, no paper to mess with.

Any Fiberglas insulation should always be used inside the air barrier. Any air moving through Fiberglas reduces the r value to what, almost zero?

The Building Performance Institute’s, Building Analyst Standards has a fairly good, easy to follow, guide to Insulation Installation quality which reflects penalties for gaps or spaces between insulation and framing or other building surfaces. I read that guide to indicate close to an 80% penalty with a 3/8” gape 14 inch long, The guide can be an effective, credible, exhibit to provide to owners, builders, building officials, and/or others who continue to resist these basic, inexpensive, and effective quality, construction practices. The BA Standard is especially effective in jurisdictions which are regulating rebates or incentives, as they often require a qualified BPI Building Analyst’s combustion safety check to issue a check.

Arthur: Yes, the BPI standards have a lot of good information in them! Here’s the link to all of their standards, for anyone who wants some extra reading. They’re free to download.

https://www.bpi.org/standards/current-standards

Flammable cardboard and foam are not suitable for this application.

Reference:

IRC R302.10.1 Insulation

Insulating materials installed within floor-ceiling assemblies, roof-ceiling assemblies, wall assemblies, crawl spaces and attics shall comply with the requirements of this section. They shall exhibit a flame spread index not to exceed 25 and a smoke-developed index not to exceed 450 where tested in accordance with ASTM E84 or UL 723. Insulating materials, where tested in accordance with the requirements of this section, shall include facings, where used, such as vapor retarders, vapor-permeable membranes and similar coverings.

True, with one caveat: R316.3.2 Foam plastic insulation 4 inches thick or less. Foam plastic insulation […] shall have a flame spread index of not more than 75 and a smoke-developed index of not more than 450 […]

Yes, the cardboard. And yet every inspector, in every jurisdiction we’ve built so far gave the cardboard baffles a blessing, if they were there.

Mark: Thanks for your comment. Yes, there are a lot of things in the code that get ignored in the field. As Paul has, I’ve seen cardboard baffles all over the place and never heard of building inspectors rejecting them.

Allison, would you mind elaborating on what you said about the yellow arrow, “it’s going right through the middle, too, where the yellow arrow points.”?

Paul: I did that in my reply to your other comment.

Sorry, just an impatient padawan waiting for the Jedi Master to speak.

In the case of a cathedral ceiling, i have blocking above wall plates like the photo you show, and 4′ baffles from the wall. But its a cathedral ceiling (3-12), do i need to worry about insulation falling down the slope over time and blocking the under roof deck ventilation? I.e. do i need to install baffles all the way to the ridge? I have 26″ of truss depth, climate 5a.

Interesting article. I recently added R-55 insulation to the attic of my studio building. I purchased something called attic foil which is basically house wrap sandwiched between two layers of aluminum foil. It also has many noticeable perforations designed to allow moisture to escape. But it prevents convective currents and possibly wind washing too. I am very happy with it. The insulation is nice and dry and I know it’s doing it’s job.

Matt,

Does the attic foil look suitable for retrofits in a 50 year old house with r-38 of blown in loose fill?

I think it would work well for most insulation applications except for spray foam, polyiso, etc, where it wouldn’t be necessary. You can check out their product at atticfoil.com. It is much better than other radiant barrier products out there. It is designed to lay right on top of the insulation, keeping the heat (or cold) in and letting the moisture out.

Matt: Yes, you could install a radiant barrier to prevent wind washing, but that’s not what it’s made for. Radiant barriers don’t save a whole lot of energy in new homes, but they do keep the attic cooler, which anyone who goes up there in summer will appreciate. If you’re laying down on top of the insulation, you could be turning the radiant barrier into a condensing surface, even with the perforations. Depending on how cold your climate is, that could make a mess of the insulation and your ceiling in winter. And then there’s the dirt issue. It won’t take long for a radiant barrier lying on top of the insulation to get dirty, which will greatly reduce its reflectivity and increase its emissivity. And a low-e material without low-e doesn’t do much.

I would like to submit another possible issue with wind washing. Humidity. I build on coastal NC where humidity is a big concern. Air infiltration carries with it air suspended moisture that can reach dew point when it comes in contact with our cool air-conditioned spaces. As with almost any infiltration, this condensation can be anywhere in the building envelope. The result is nice warm damp surfaces that are prime candidates for mold. Completely out of sight and in places we cannot get to. Yet I still have arguments with other builders regarding this whole “the house has to breath” nonsense.

I’ve experienced these scenarios and come to realize that in the old days we had 1/4″ plywood soffits with a 6×12 inch vent every 8 ft with substantially less air flow Bad and Good

Now with perforated aluminum the standard soffit a gigaton of air is blowing thru I now use non perforated over front door canopies and rear deck large roof over unheated deck areas and have raised truss heel heights to 18 ” with solid osb panel tightly fastenened also double anchor system truss to pane to top plate Done Fixed no more crappy cardboard chutes or flimsy sm stops As a framer this is my preferred solution

The cardboard baffles in the 5th photo make me nervous. Wouldn’t that just be opening the door (so to speak) for mold growth? (Say, in a humid climate, even if you were able to keep other sources of moisture from the attic?).