How I Got Faster Hot Water

In my last post, I told you about the plumbing work I did to begin the retrofit of my hot water distribution system. I’m bypassing the original too-long, too-big copper pipes with shorter, smaller runs of PEX tubing. My goal is to get faster hot water and reduce the amount of water wasted while I wait. Since last weekend, I have now finished two of the three runs I’m changing. And I have some results to share with you.

The existing hot water distribution system

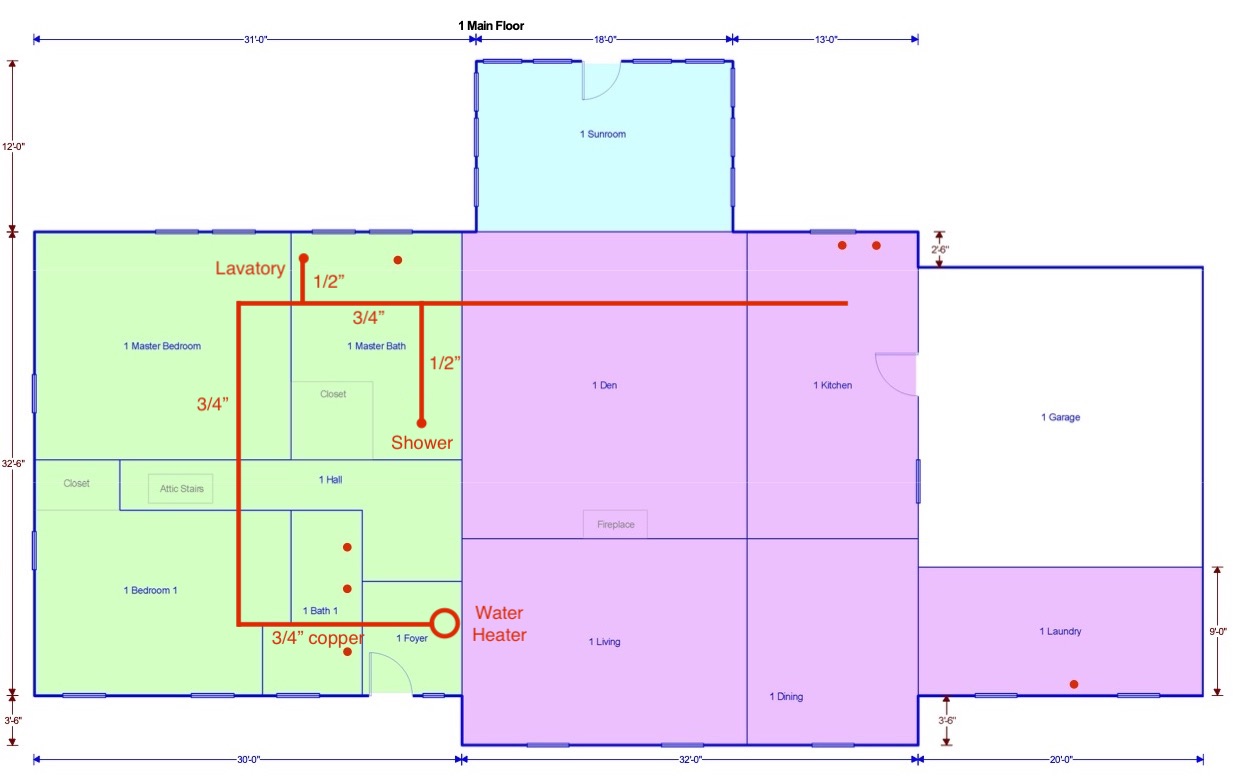

My house was built in 1961 and has a poorly designed hot water distribution system. The schematic below shows the water heater, the trunk line, and the branches to the two fixtures I’ve improved. (The water heater is actually in the basement below, not the foyer. The red dots are the hot water fixtures.) The primary bathroom isn’t really that far from the water heater, as you can see. But the hot water pipes don’t take the most direct route to the lavatory and shower.

The hot water rectangle for my house isn’t as bad as it could be. The water heater is near the middle of the house, and the bathrooms (basement and main floor) are stacked and close to the water heater. The kitchen is pretty far away, and the laundry room is farther. The hot water rectangle is 50%, which is bad for a two-story house.

The hot water rectangle is just one part of the problem. That indicates the fixtures and water heater are spread out so the pipes are longer than they could be. The other issue is that the pipes are too big. The trunk line is 3/4″ copper all the way to the kitchen. The branches are 1/2″ copper. That’s a lot of water in the pipes that gets in the way of the hot water traveling to the fixture. You can read more about that in my article on why your hot water takes so long.

The retrofit

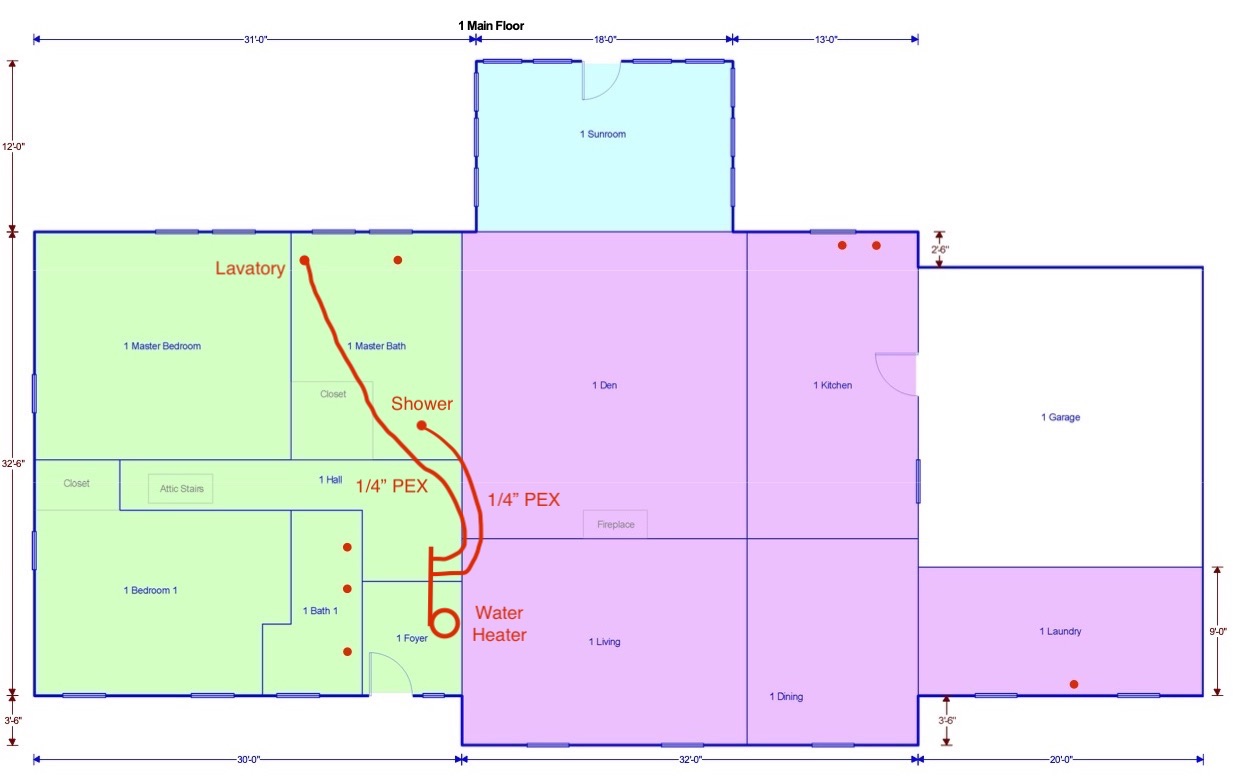

I’m not changing out the whole plumbing system (not yet anyway), but I’m fixing three of the most used fixtures: the shower and lavatory in the primary bathroom and the kitchen faucet. I built and installed a manifold that lets me run three PEX tubing lines to those fixtures. And now I’ve got my two bathroom fixtures fixed.

The schematic below shows the new runs for those two fixtures. Both now are served by shorter, smaller pipes with a lot less water in them. I could have made the lavatory run even shorter if I had rotated the manifold 180°, but that didn’t occur to me until I made the sketch here.

The results

I tested both of those fixtures for time to hot water and the amount of water wasted while waiting. I did the testing when there had been no hot water call for at least 8 hours, usually first thing in the morning.

Lavatory, before: 80 seconds, 1.5 gallons

Shower, before: 105 seconds, 2.5 gallons

The shower was actually closer to a minute when we bought the house, but last year I changed the 2.5 gallon per minute showerhead to a 1.5 gallon per minute model.* (It works really well so I ordered another one for the other main floor bathroom.)

After installing my PEX lines, the wait time and wasted water are:

Lavatory, after: 23 seconds, 0.5 gallon

Shower, after: 20 seconds, 0.45 gallon

That’s not instant hot water, but it’s a huge improvement. And the water gets warm before the 23 and 20 seconds I noted above. With this improvement, I’ll actually use the hot water in the lavatory sometimes. It also means that I won’t have to turn on the lavatory and bathtub hot water faucets at the same time as the shower to speed the hot water along. Yay!

I still have room to improve upon those numbers. The majority of the volume of water is in the vertical pipe from the water heater to the manifold and in the manifold itself (photo just above). I’ve got those pipes mostly insulated now (lead photo at top), but there are still some gaps. If I got nuts on insulating and air sealing around those pipes, I’m hoping the water in there will stay hot.

Wrap-up

There you have it. Getting faster hot water is a matter of reducing the length and diameter of the hot water pipes. I used two 1/4″ PEX lines here, but you need to be careful in sizing your pipe if you do this. Going all the way down to 1/4″ works for runs less than about 25 feet long and only if you have enough pressure. See my article on my friend David Wasserman’s hot water retrofit for more details.

And yes, another way to get hot water would be to use a recirculation system. If you go that route, choose the demand type system, not the continuous. Even on a timer, the continuous recirculation system uses far more energy than the demand system.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He also has written a book on building science. You can follow him on Twitter at @EnergyVanguard.

Related Articles

Why Your Hot Water Takes So Long

A Hot Water System Retrofit for an Old House

* This is an Amazon Associate link. You pay the same price you would pay normally, but Energy Vanguard may make a small commission if you buy after using the link.

Comments are moderated. Your comment will not appear below until approved.

This Post Has 15 Comments

Comments are closed.

Hi Allison,

Just wondering why you chose this solution versus a recirculation system? Knowing you, I imagine you researched both options thoroughly. Wouldn’t the recirculation route result in almost instant hot water at the taps?

My kid’s 2 story house has their kitchen on the last stop and it takes 2+ minutes for the hot to arrive.

Greg: Yes, a demand recirculation system would give me nearly instant hot water, and that might be the better overall solution for my house. I had some talks with Gary Klein, and that’s what he recommended. But I wanted to do the PEX bypasses to see how much improvement I could get without adding a pump. When I gut and remodel the basement, I may redo the whole plumbing system so I have the option to go that route then.

We put in a demand recirculating system many years ago and solved the problem—the water heater is in the garage and the master bathroom is at the opposite end of the house. But it did not solve the shower problem: a 15-sec wait for hot water from the sink to the shower. During the last mega-drought we collected the “waiting” water in a bucket and used it to flush the toilet (it was softened water and unsuitable for plants) . Now we are in a worse drought but I haven’t brought the bucket into play yet. Note: the first re-circ system died after about 20 years, and it cost $900 for the new pump (incl installation). Out here in the desert , water is more precious than greenbacks, I guess.

Donald: Yes, a demand recirculation system is an excellent option, and I may do that with my house, too.

Allison, Have you noticed any reduction in flow, particularly at the shower which has a higher demand ? Could you have continued the shower branch on to the lav to reduce the length of tubing subject to heat losses? That seems feasible as long as you don’t often have simultaneous demand from both fixtures. In my 2 story house with buoyancy powered recirculation, the master bathroom is last on the riser, so the family bath, which is upstream of it, gets the benefit of instant hot water too. The kitchen branch is also on the basement main serving the 2nd floor, so it too has warm water, except for the 12 foot long, 1/2″ diameter branch from the main. Single story homes are very convenient, but they do produce some very long pipe runs.

Gene: No, the flow is the same. I was getting 1.4 gallons per minute from the shower before and am getting the same now. I have lots of pressure: 60 psi and I probably could get more by adjusting the regulator. Yes, I could done both the shower and lavatory on the same run, but I would have gone to 3/8″ tubing if I had just to keep anyone from getting a cold blast in the shower if another person turned on the hot water at the lavatory.

check the compatibility of any sealant used on the PEX piping with the manufacturer ..Have been told certain sealants can weaken the PEX pipe .

Robert: I didn’t use any sealants on the PEX. They’re connected with Sharkbite push fittings. Checking sealant compatibility is always a good idea, though.

Thanks, Allison. I’ve had a Chilipepper (https://chilipeppersales.com/ [no affiliation]) on demand pump for years (an older, noisier model than their new pump). I’ve also considered installing smaller pipe runs to the kitchen and bath. When I tore out the galvanized pipe and re-plumbed with copper, 3/4″ main runs and 1/2″ fixture runs were supposed to be ideal. They’re not.

The High Sierra shower heads are great – bought mine directly from High Sierra due to a love/hate relationship with the world’s largest retailer. If I had to buy another, I would definitely go with the 1.25 gph.

As a home inspector of 35+ years, I appreciate your articles. Building science rocks!

Jim: I think the 1.25 gallon per minute model of the High Sierra showerhead must be new. When I bought mine last year, I’m pretty sure 1.5 gpm was the lowest flow rate they had. I remember hesitating about whether or not to go with the 1.8 gpm model because I didn’t know if I’d be happy with it or not, but I did buy it and it works great.

Thanks for the kind words, Jim!

Allison – all High Sierra products are now available with the 1.25 gpm option. I couldn’t decide between the 1.5 and 1.25 when I bought the first shower head.

There’s a site wide sale through Monday – 20% off (LaborDay20) – just ordered the 1.25 to check it out. I think it’ll be fine.

Sealing the spaces used in running the PEX piping ; Most of us are used to copper which is highly resistant to most building sealants .. PEX may be susceptible to the solvents used in some foams and caulks to fill in the holes drilled or cavities created to route the PEX .. Usually the manufacturer of the PEX can provide a list of products to not use directly against the PEX pipe , which may also include certain types of pipe insulation.

In California (and the rest of the southwest) we have a bit of a water crisis.

For retrofit, I’m of the opinion that if a decent demand recirc system can be engineered and installed at a reasonable cost, it is the best solution.

I’d love to see better building code for new home construction. Better design, as you’ve mentioned, with a more centrally located DHW system overall, both in source and point of use. If an architect wants to spread it out, then code should require demand recirc.

My house was built 50 years ago with every point of use as far from the water heater as it possibly could be. Human nature… it’s just not *really* a concern until it’s a full on crisis.

For outdoor irrigation, I switched from water to tequila. Big reduction in water consumption. Although, anecdotally there has been an uptick in the volume of bird fights. I’m not sure if it’s related. More data will have to be collected.

Wow 1/4″! – When I measured the amount of water I was wasting before the hot water was available, I used 3/8″ because I felt that the pressure here wasn’t up to the job. (would’ve been better if I actually measured it)

Christopher: Yes, you do need to be careful with sizing the pipe. If you don’t have good starting pressure or if the pipe is long and has significant pressure drop, you need to increase the size. The two I wrote about in this article were short and my pressure is 60+ psi. I’ve done the kitchen pipe since then and used 3/8″ there because it’s a longer run.

Here’s what I wrote at the end of my previous article about this kind of retrofit:

Caution: Prescriptive plumbing codes don’t allow pipes as small as 1/4″ so you may need an engineer to help if you want to go that small. You need to know the flow rate required at the end of the line. To use 1/4″ PEX tubing, it should be about 1.8 gallons per minute or less. Also, if you need to run the PEX more than 25 feet, you’ll need to go to a larger size, too. To get a better handle on what you need, use this plastic pipe design calculator.

The full article is here:

A Hot Water System Retrofit for an Old House