Why I’m Not a Fan of Positive Pressure Mechanical Ventilation

We want our homes to be airtight. It saves energy. It helps keep water vapor from getting into places where it can cause problems. It keeps bad air from moldy crawl spaces and contaminated garages out of the house. It just makes sense. Tight homes, though, need a way to replace stale indoor air with outside air. That’s the role of a mechanical ventilation system. Of the three types of mechanical ventilation systems, home builders in the Southeast have latched onto one that has a number of problems: the positive pressure system. (The other types are negative pressure and balanced.)

We want our homes to be airtight. It saves energy. It helps keep water vapor from getting into places where it can cause problems. It keeps bad air from moldy crawl spaces and contaminated garages out of the house. It just makes sense. Tight homes, though, need a way to replace stale indoor air with outside air. That’s the role of a mechanical ventilation system. Of the three types of mechanical ventilation systems, home builders in the Southeast have latched onto one that has a number of problems: the positive pressure system. (The other types are negative pressure and balanced.)

We want our homes to be airtight. It saves energy. It helps keep water vapor from getting into places where it can cause problems. It keeps bad air from moldy crawl spaces and contaminated garages out of the house. It just makes sense. Tight homes, though, need a way to replace stale indoor air with outside air. That’s the role of a mechanical ventilation system. Of the three types of mechanical ventilation systems, home builders in the Southeast have latched onto one that has a number of problems: the positive pressure system. (The other types are negative pressure and balanced.)

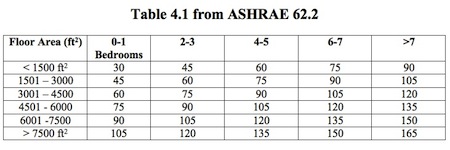

First, a brief review of mechanical ventilation requirements. Paul Raymer, one of the gurus on this topic, wrote a guest post on that topic in the Energy Vanguard Blog last year. The standard that sets the guidelines for how much we need is called ASHRAE 62.2-2010. It specifies a couple of ways that you can figure out how much outside air you need to bring into your home, one of which is by using the table below.

What’s wrong with positive pressure mechanical ventilation?

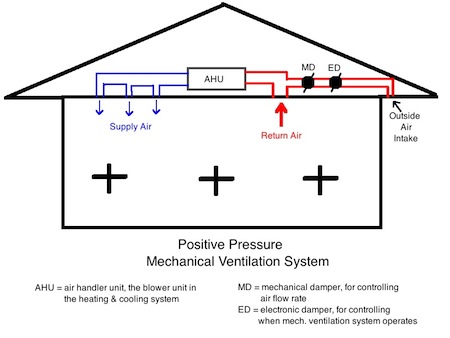

First, let’s look at how a positive pressure mechanical ventilation system works. By positive pressure, I mean that the air pressure inside the house is higher than outside pressure, which tends to push air from inside to outside. You can bring in outside air and get positive pressure in the house in one of a few ways, but the main way that home builders do it around here is by using the air handler unit (AHU) in the heating and cooling system, as shown below. (Yes, I’ve shown the ducts in the attic here because so many are. Putting ducts in an unconditioned attic is still stupid.)

Here’s a brief rundown on what’s going on:

- When the heating & cooling system is running, the blower in the AHU pulls air from the house on the return side, conditions it, and puts it back into the living space through the supply vents.

- Whenever the electronic damper is open in the ventilation duct, the AHU is also pulling a little bit of air from outside and mixing it with the air from the house. This extra air added to the house is what provides the positive pressure.

- The amount of air that comes through the ventilation duct depends on the size (and other characteristics) of the duct and how the mechanical damper is set (and ideally is based on what ASHRAE 62.2 requires).

- The electronic damper is wired to a controller that determines when ventilation air is allowed to enter.

- The electronic damper can be open or closed when the heating or cooling system is operating.

- The electronic damper also can be open when the house doesn’t need heating or cooling, in which case it will run the blower in the AHU independently of the furnace, heat pump, or air conditoner.

- The controller allows the homeowner to set how much ventilation air the home gets.

This type of mechanical ventilation system has been the most popular one installed in high-performance homes in the Southeast over the past decade. It’s relatively inexpensive, as the duct, dampers, controller, and installation generally add only about $300 to the cost of the HVAC system. Positive pressure also has the advantage of helping to keep humid air from infiltrating into the house.

Still, I’m leery of this system for a number of reasons:

- You’re using the biggest motor in your home, the blower in the AHU, to move a small amount of air. The AHU typically moves 1000 to 2000 cubic feet per minute (cfm) of air, but most homes need only 50 to 100 cfm for ventilation (see table above).

- When the controller brings in outside air at times when the heating or cooling system isn’t operating, not only are you using a motor that’s way too big, but the outside air comes in at outside conditions: cold in winter and hot and humid in summer.

- A lot of these systems don’t bring in as much air as they’re supposed to. I was just talking to someone this week who finished a master’s thesis in building science on this very topic. She studied this type of system in a multi-family development and found that the systems underperformed because there wasn’t enough static pressure to pull in the required amount of air.

The last problem above should be easy to fix. Design and install everything properly and then go through a commissioning process to ensure that it works. One of the nice things about ENERGY STAR Version 3 is that not only is mechanical ventilation required for all homes, but the HERS rater has to measure the air flow to make sure it works.

The first two problems are serious drawbacks that don’t have easy solutions. OK, if the AHU has a variable-speed, electronically commutated motor (ECM), that can help a lot with the first problem, but the fact is most blowers still use fixed-speed motors.

The problem of bringing in unconditioned air into the house using the AHU, though, isn’t as easy to solve. One potential problem with bringing outside air into the duct system in summer when the air conditioner isn’t running is condensation in the ducts. In a place like Charleston, SC, for example, where the dew point pushes 80° F in the summer, it’s not hard to imagine condensation happening.

These systems have become popular in the Southeast because they’re inexpensive, but maybe it’s time to rethink whether we should be installing them.

What’s the solution?

For hot or mixed humid climates, which the whole Southeast, what kind of ventilation system should you use? If positive pressure is good for combatting the infiltration of humid air, that means a negative pressure system wouldn’t be so good. That leaves the balanced system: a heat recovery ventilator (HRV) or enthalpy recovery ventilator (ERV). Martin Holladay wrote a good article on how to choose between an HRV and an ERV a while back, so that would be a good starting point for learning more.

Do you have a mechanical ventilation system in your home? Which type? How well does it work? If you’re a home builder, HVAC contractor, or HERS rater, what’s your experience with positive pressure systems of the type I described above? Any problems?

Related Articles

Breathe! – Get Fresh Air into Your Home with ASHRAE 62.2

Dew Point — A More Meaningful Measure of Humidity?

How Much Air Leakage in Your Home Is Too Much?

Photo of fire breather by leepus from flickr.com, used under a Creative Commons license.

This Post Has 22 Comments

Comments are closed.

What about retrofits? I agree

What about retrofits? I agree with you that a balanced method with HRV or ERV is best, but how do you communicate to a homeowner that they should fork over an extra $2-3K for one?

I’ve tried both adding a duct to the outside and putting a better bath fan in with a timer switch. I can’t say I’m in love with either method:

1. Positive pressure = condensation problems.

2. Negative pressure = potential backdrafting.

Any suggestions on how to talk a homeowner into doubling the cost of an attic job for a problem they just learned about?

As a HERS rater, I had to

As a HERS rater, I had to look at my own home. I found my largest electric bill was February. I live in KS, a mixed humid climate. Why was Feb. a scorcher on my electric billing? The house gets stale, or musty (she never says humid) or what ever the LOML is sensing and so, on goes the AC. 40 degrees outside, AC can be running. ( I have taught her to open windows at 35 or below. )

So my goal became to take this mid sixties 2 story, four level structure, and fix the envelope, and replace the 20 year old HVAC.

So some air sealing, and lots of insulation later, new HVAC; I have a higher performing home.

At test in: Tectite Calculates:

Airflow at 50 Pascals: 2191 CFM ( +/- 0.4 %)

(50 Pa = 0.2 w.c.) 8.08 ACH

At test out: Tectite Calculates:

Airflow at 40 pascals: 1551 CFM ( +/- 0.3 %)

(50 Pa = 0.2 w.c.) 5.51 ACH

I installed a Fan Tech ERV at 40 CFM. Runs continually. Exhaust is from lowest level, and Supply is into the highest level. ResVent 62 (by Rick Karg) calculates 32 CFM for 62.2.2010 compliance VS the table above at 75 CFM)

In Mar and April, the lows here were in the 60s and the highs were in the mid to high 70s. We had many 8 – 15 hour periods of the home staying in a 70 – 74 range with no thermostat calls.

The ERV was originally plugged into the HVAC to run when the thermostat made a heat or cooling call. The contractor’s idea. LOML was turning on the AC. I moved the plug to a regular outlet, now runs continually, and we get the long periods of no thermostat calls.

LOML last summer liked 68 at night. She likes 70 this summer. Thermostat located one level below the bedroom. Last summer, she liked 72 during the day. This summer 75.

Without the lower flowing ERV running continuously our higher performing home would still be using the same thermostat settings as last year.

Nate: The Fan ted unit was

Nate: The Fan ted unit was installed for LT $1 K

I would be wary of placing

I would be wary of placing too much trust in an ERV in a hot-humid climate. I am just a homeowner but it looks to me that unless conditions are just right, it is yet another $3000 appliance to sell and profit from — versus a real solution to a real problem.

Applying that same money to upgrade the air handler to ECM type would address the energy question, and work toward solving common AC problems as well. Everybody replaces their AC from time to time, and when that happens they should be encouraged to spend some extra dollars on this more efficient technology.

You fear in-duct condensation by running the ventilation without AC in hot-humid summer? Who has ever seen this? I think that worry is ill founded. Any ventilation system which does not supply sufficient air DURING the AC cycles, is just wrongly designed. In any situation with reasonably sized AC and fresh air intake, the problem should see the FA vent closed during a substantial part of the cycle, not open and ventilating when AC is not needed.

The problem I see with ERV in hot humid climates, is its job is 95% humidity control, there is a very minor amount of sensible temperature energy to transfer. And the latent (humidity) energy transfer is how efficient, maybe 50-60%? If you flow a larger amount of air thru the ERV, which usually is prescribed, then you could actually be bringing MORE humidity into the house than the simpler fresh air vent into the AC return plenum. To me that would make it a wasted expense.

Finally consider how many houses leak through random air infiltration. A supply-only system will tend to offset that leakage, a benefit you will not get with a balanced ventilation system. In a heating dominated climate positive pressure spells danger, but in a hot-humid climate the outward air leakage is lower dew point than outdoors and I see no danger at all from that.

If you have many days of weather both mild and humid, then you might introduce issues I have not addressed, I acknowledge that. But in a hot-humid climate I see several advantages to supply-only ventilation, and see positive pressure as an asset.

Allison,

Allison,

Advanced Energy has over 5000 System Vision (systemvision.org) homes (mostly Habitat for Humanity) throughout North Carolina and they all use the positive air approach. They used to require a Air Cycler – but this was discontinued due to the comfort issues mentioned above. They have since done away with the air cycler and now depend on the thermostat to create the ventilation demand. So yes there are some short periods of the year when they are not getting exactly what 62.2 requires but to my knowledge we have not seen condensation problems in the ducts and these home have guaranteed heating and cooling bills in the $25/month range. So you should contact Bryan Coble at Advanced Energy to see if they have an opinion.

I personally have a hard time with the Balanced Systems because if a homeowner will not change a $1 filter – what makes us think they will take care of a $2000 ERV? When teaching my BPI classes and Home Performance Contracting classes I suggest that balanced systems should only be offered with Maintenance Contracts – which as it turns out is the secret to many companies success – such as Green Homes America – They claim that over 50% of their new jobs come from Maintenance contracts or friends, family, or neighbors of those who have the maintenance contracts.

And for that matter we are getting so proud of ourselves for figuring out how to install ventilation systems to ASHRAE and getting everything just perfect with Manual J but then what happens when the homeowners move out and an entirely different load moves in – (more family members, lots of plants, jacuzzi – because everything we design and install is so close to exact – there is no fudge room for the natural evolutions of the modern home.

whew! Rant off!

I don’t often find existing

I don’t often find existing homes’ ach is low enough to require fresh air in most cases.

in new construction, we have added the following set up for fresh air with great success.

as I’m not a fan of motorized dampers as it is another part to fail and be replaced.

from return air, 6″ flex duct with barometric damper. (skuttle 2-16) damper is set to required cfms required.

the barometric damper has a weighted lever for the cfm adjustment requirement.

this flex duct (with damper)

is installed under patio, porch or appropriate soffit.

acessable for homeowner and not facing north.

at the termination of this duct to exterior is a 12×12 filter back grill with filter.

this way the air is first cleaned, then measured and finally allowed in to return to be dehumidified before entering the house.

in my hot humid climate dehumdification is necessary.

imo & experience this is the most cost effective way to do this.

rather than erv, air cycler, motorized dampers this install is less than $1,000 installed. in trying to find affordable options for my homeowners, this has worked very well.

try contolling fresh air with

try contolling fresh air with humidstat

MJ wrote:

MJ wrote:

> Any ventilation system which does not supply sufficient air DURING the AC cycles, is just wrongly designed.

I agree with much of what you wrote but if a home is tight enough to warrant mechanical ventilation, then off-cycle ventilation may be necessary. It’s not unusual for an efficient home to experience several weeks with no heating or cooling load in swing seasons (record for my current home is 8 weeks). Although I’m of the opinion that mechanical ventilation is often oversold by the home performance industry, and I definitely favor opening windows in swing seasons when conditions are favorable, I do worry about off-cycle IAQ in small homes that are “toilet flushing” tight (a Tooleyism?)

@Scott, one of the problems with System Vision homes (at the time I was involved) is that they didn’t require ECM blowers, so the off-cycle energy penalty was severe. I wasn’t aware they stopped using air cyclers. I’m very surprised to hear there were comfort issues since 1) ventilation CFM was verified (e.g., not over-ventilated), 2) outside air was mixed with perhaps 800 CFM of indoor air and spread throughout the home, and 3) the cycler they used didn’t operate at extreme conditions.

You’ve piqued my curiosity. I’ll catch up with Brian next week to find out more.

The big problem with ECM’s is

The big problem with ECM’s is heat exchangers don’t fail very often in furnaces. A cracked heat exchanger is normally required before a homeowner will fork out the money for a new furnace. At the unexpected point of furnace failure, the additional cost for an ECM can be tough sell. Builder furnaces tend to last a LONG time, often 2 to 3 decades before exchanger failure. It’s rare for me to find a house built after 1990 that DOESN’T still have the original furnace.

Sure there are retrofit ECM’s, but they loose many of the benefits that a furnace with ECM offers. Again there is the cost issue, most homeowners don’t want to upgrade the failed motor on their 5+ yr old furnace.

A/C’s on the other hand only tend to last about 15yrs, when they die homeowners often just want to replace the condenser and possibly the A coil. Some will go for a whole new system with the logic that it costs less to change the furnace while the A coil is already being replaced.

@Allison, I think you’re

@Allison, I think you’re overreacting by making a general case against supply-only (positive pressure) ventilation.

First, I do agree that using a PSC blower for off-cycle ventilation is a bad idea. It will eat your lunch. But I bet a high percentage of homes that are tight enough to require ventilation have a variable or multi-speed ECM blower (100% of projects I design). Variable speed blowers typically consume less than 100 watts in fan-only mode.

When you consider that a substantial portion (perhaps more than half) of ventilation occurs on-cycle (zero fan energy), the annual fan energy for ventilation is actually lower than any other option.

In a retrofit situation where the air handler has a PSC motor, if the home is tight enough to require ventilation, I’d make sure the cycler operates the fan on it’s lowest setting (all blower motors have multiple speed taps), and I’d make sure I take the infiltration credit when establishing the target ventilation rate. Do you still think a $2-$3k ERV would have a lower lifecycle cost?

As for your #2, see my comment to Scott. Mixing 10% air at 10F with 90% air at 70F yields about 64F air. I chose a very conservative mixing ratio to make a point.

#3 is not a valid reason. I would say the same thing about balanced systems. As you point out, it all boils down to proper design and commissioning.

You also raised the condensation issue. Keep in mind that the cycler only operates the blower off-cycle if there’s no heating or cooling call for an hour (typical), so the duct system is no longer cold. This is one reason to use a cycler rather than continuous fan mode, which is always a bad idea in humid climates as it can cause re-evaporation of water on coil and catch pan.

BTW, you failed to mention another ventilation option: non-recovery balanced ventilation (e.g., Fantech AEV 1000).

I’ve found air cyclers are

I’ve found air cyclers are used on PSC blowers a lot. A local builder, Ideal Homes uses them on most of their energy efficient homes. I have yet to see an air cycler on a VS system. I have yet to see a builder installed VS system in new construction in a home under $250k. VS systems are typically installed as replacements in $150K+ homes. Sure VS systems are cool, but less than 5% of homes in our area have them installed.

Using hte low speed tap on a

Using hte low speed tap on a PSC blower doesn’t save much energy. A typical 1/3 HP blower motor uses 500W on high, 400W on low. Airflow drops considerably, but power consumption does not. Try a Kiil-a-Watt on a PSC furnace and see the difference. It’s much better to reduce the time on the PSC blower vs the speed in order to maintain air changes per hour.

The rare variable speed machine is a different story, run it on low for longer periods of time.

Bob wrote:

Bob wrote:

> A typical 1/3 HP blower motor uses 500W on high, 400W on low.

Perhaps for the largest models, but those typically have 1/2 hp motors. Here are some examples of several Lennox models (based on 0.5″ WC at lowest speed tap). Lennox is one of the few majors that publish watts on blower tables.

air handler (CBX32M)

1.5/2.0 tons – 190W (1/5 hp)

2.5 tons – 190W (1/3 hp)

3.0 tons – 255W (1/3 hp)

3.5 tons – 310W (1/3 hp)

furnace (G51MP/GM51MP)

2.0 tons – 230W (1/5 hp)

3.0 tons – 325W (1/3 hp)

The point is, without doing a life-cycle cost analysis, it’s impossible to generalize about the trade-off between cycling a PSC (positive pressure ventilation) vs. forking out thousands for an ERV or HRV.

But I agree it’s better to increase vent CFM and reduce the cycle time, especially with PSC.

The 500W/400W ratings came

The 500W/400W ratings came from me testing my own system. It’s rated for 3.5ton with a 1/3HP blower.

IMHO it’s odd that Lennox uses 0.5″ at the LOW speed tap as a baseline to determine motor wattage on a system that’s rated for 0.5″ on high. If they used 0.5″ on HIGH speed the motor wattage would read considerably higher.

Here’s the blower table for

Here’s the blower table for one of the models I referenced: http://bit.ly/NjDSYg

A blower table will show the entire static range for each speed. I chose 0.5″ for my examples. Perhaps a bit conservative for low speed, but again, my point was simply an argument against generalizing (which admittedly I’m sometimes guilty of).

Nate A.: I

Nate A.: I don’t have a good answer for you right now for retrofits. The $300 Panasonic Whisper Comfort ERV has been popular, but I don’t know how well they perform.

John N.: Sounds like you’re on top of the situation in your home, but not every home is a HERS rater.

Mark J.: There are ERVs that are far less expensive than $3000, but yes, maintenance is definitely an issue. Martin Holladay wrote about that very issue a couple of weeks ago at Green Building Advisor. Your statement that, “Any ventilation system which does not supply sufficient air DURING the AC cycles, is just wrongly designed,” isn’t really true. With 1.5 tons being the smallest standard AC you can get, it’s easy for the AC to be oversized, especially in high-performance homes.

Scott S.: I don’t see how just the normal runtime of the AC can provide enough ventilation air to meet ASHRAE 62.2 in a small, efficient Habitat home. With 1.5 tons being the smallest AC you can get and the cooling loads on some of those homes being less than a ton, I’m sure, it seems like it’d be difficult. I’ll definitely talk with Bryan to see what they’re doing because I haven’t seen positive pressure, central fan systems that work well yet.

Allison wrote: <

Allison wrote:

> there are ERVs that are far less expensive than $3000…

In retrofit, probably not much less than that, especially when you account for commissioning. In new construction, the lowest ERV quote I’ve seen was $1800, but the contractor retracted his bid when I prompted the builder to inquire about commissioning.

I caught up with Brian Coble

I caught up with Brian Coble earlier today. He confirmed that Advanced Energy stopped using air cyclers in Systems Vision homes due to comfort complaints, as well as other reasons. But he clarified that it wasn’t because the supply air was too cold, but rather an issue of excessive air movement, which I think we all know can create discomfort when it’s cold outside.

So I read too much into Scott’s comment, perhaps because Allison framed the comfort issue in terms of distributing unconditioned air.

But Brian raises an important point. In general, it’s a bad idea to operate the blower off-cycle in winter. However, in a high performance homes with a low design airflow, say 0.25 CFM per SF (about the upper limit of the homes I work on), running the fan at half speed, especially if registers are properly designed and adjusted, shouldn’t be an issue.

Although I’ve never had complaints from the handful of clients with PPV, I acknowledge that it requires careful attention to design by someone who understands the issues discussed in this thread. But I also remind folks of numerous reports of poorly installed HRV’s and ERV’s.

Whole house dehumidifiers can

Whole house dehumidifiers can provide positive pressure ventilation without the problems listed above. An efficient whole house dehumidifier will ventilate using a fraction of the fan motor watts of the air handler and the dehumidifier will remove water vapor before introducing the mixed ventilation air into the house. The more efficient whole house dehumidifiers are more efficient at removing water vapor from the air in a house than the AC system.

Efficient whole house dehumidifiers are more expensive to install than the simple positive pressure ventilation system described above (or a bath fan negative pressure system), but they will provide a very comfortable house at a low operating cost.

Maintenance is the main challenge for positive and balanced ventilation systems. Many homeowners do not maintain these systems and some contractors do not check the condition and performance of the ventilation systems during the seasonal check-up. If the outdoor air grille and filter are not maintained clean, the system will not ventilate as designed. With a dirty outdoor grille and/or filter, the simple positive pressure system will not provide adequate ventilation, but will provide some reduced amount of ventilation.

With a dirty outdoor grille and/or filter, the balanced ventilation system will become a negative pressure ventilation system. ERV and HRV systems offer a good payback for houses in extreme climates, but a much poorer payback for houses in moderate climates – they use more fan power with their two fans than a simple positive or negative pressure ventilation system (that does not require the AHU fan to operate). I have seen balanced systems with clean filters in the ERV/HRV, but a nearly plugged insect screen on the outdoor duct. A marginal or non-existing payback for much of the US climate with a tendency for poor maintenance can leave many houses with a negative pressure ventilation system that was expensive to install and is expensive to operate.

Allison,

Allison,

The title of your article is misleading. What you’re “not a fan of” is NOT positive pressure (supply) ventilation, but using a central AHU to provide it. I agree that the system you describe – and object to – is a worst case scenario in terms of energy efficiency, insufficient outdoor air supply, and intermittent (vs continuous) operation. Fortunately, there are better – more efficient and effective – ways to provide supply ventilation. Using a small, right-sized, efficient (high cfm/W) fan & ventilation-only ducts that are independent of the central FA system provides these advantages: the ability to pull outdoor air from a known (unpolluted) location, pull it through a MERV 7-12 filter, deliver small amounts (20-25 cfm each) reliably to bedrooms and living areas (even when doors are closed), run continuously (non-stop), and slightly pressurize the home. Because of these advantages, I consider “independent supply ventilation” to be the “better half” of balanced ventilation, which doesn’t always make sense due to budget and/or climate. The reason most people are not aware of this option is that no major manufacturers promote it. Of course, intermittent exhaust fans are always needed in bathrooms and kitchens, to remove moisture & odors, which is what they do best.

Thans for information

Thans for information

Live in Canada with cool

Live in Canada with cool winters. Have wood and a gas fire place. Sometimes there is a gas exhaust smell coming from the gas fire place. The house is only 3 years old and has a air exchanger. Large exhust for stove. I believe that we are having a negative air in the house sometimes and is pulling air from gas fire place. How can I check for positive or negative air pressure.