Is Heat Pump Supply Air Too Cold for Heating?

Oh, the dreaded “cold blow.” That’s HVAC technician-speak for a forced air heating system that blows cold air on the occupants of a home. Is it really a problem? Is the supply air from a heat pump really cold? How many homeowners experience this problem? And is the problem really due to using a heat pump instead of a furnace?

Supply air temperature

How warm is the air after being heated by furnaces and heat pumps? Furnaces do make hotter air than heat pumps, so let’s look at some typical temperatures for each type of heating system.

Furnace – If the furnace is installed properly (more on that below), the air coming off the heat exchanger should be somewhere around 150 °F (66 °C). It might warmer. It might be cooler. Most of the time, though, it cools off some by the time it comes out of the vents. Let’s say it comes out at 125 °F (52 °C).

Heat pump – Again, assuming proper installation, the supply air coming off the coil of a heat pump will usually be between 90 °F (32 °C) and 110 °F (42 °C). That photo above shows that the temperature of the air coming out of my heat pump was 105 °F (40 °C) when I took the reading.

So, yeah, a furnace makes hotter air than a heat pump. Does that make it better? Hmmmm. Let’s explore that idea.

Is that air warm enough to warm your house?

The recommended indoor design temperature for winter is 70 °F (21 °C). Can a heat pump’s 90 °F air coming out of the vents warm the indoor air to 70 °F? Of course it can. Can it heat that air as much as 125 °F furnace air? Of course it can.

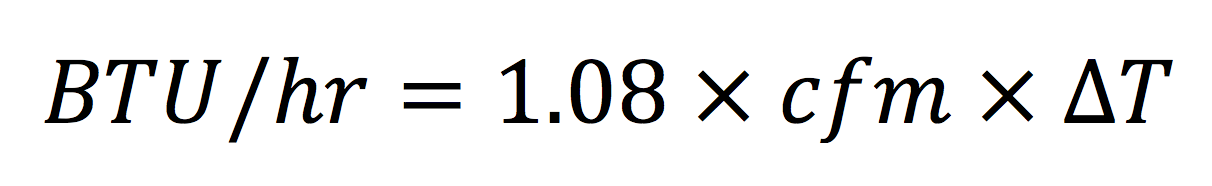

The key to heating a house sufficiently with cooler air is to increase the air flow rate. It’s all about the amount of heat being transferred, not just the temperature. Using the old-fashioned American units, the rate of heat transfer depends two main factors: the air flow rate and temperature difference (ΔT). Here’s the equation we use to do calculations for this:

Don’t worry. I’m not going to do any more with it except tell you that’s how I got the following air flow rates for heat pumps and furnaces. If you want more details about this equation, see my article on air flow and heat transfer.

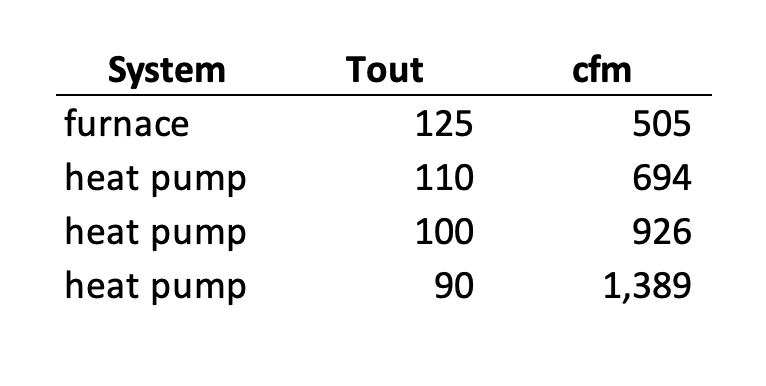

Let’s say the heating load on your house is 30,000 BTU/hr, and you keep the indoor air temperature at 70 °F. Those numbers are fixed for our example. The input numbers that change are the supply air temperature of the heat pump and furnace. From those, we can calculate how much air we need to move to keep the house at the desired temperature.

So there’s no problem keeping the house warm enough with lower temperature air. You just have to move more air because each cubic foot of air has fewer BTUs in it.

A cardinal rule of duct design

When I hear of someone complaining about cold air blowing on them from their heating system, my first thought is about duct design. One of the most important rules of duct design is this:

Don’t blow air on people!

The air coming out of the vents is warmer than room air in winter and cooler in summer. That can lead to comfort complaints any time of year. The way to prevent those complaints is to follow the rule above during the design process. Failing that, changing the type of supply vent or maybe adjusting the louvers can help mitigate the problem after the fact.

By not blowing air directly on the people, that conditioned air gets a chance to mix with the rest of the air and come to the proper temperature by the time the occupants feel it.

What else can make the heated air cooler?

It seems, though, that heat pumps get more blame for “cold blow” than furnaces do. Yes, they send lower temperature air into the house, but as I said above, proper design should eliminate that as an issue.

But there is another reason people might complain about heat pumps blowing cold air, too. Heat pumps go into a defrost cycle occasionally to keep ice from building up on the outdoor unit. During defrost, the system isn’t heating and may blow cooler air into the house. Some systems use auxiliary heat to warm up that air during defrost, but not all heat pumps have auxiliary heat.

Cold blow can happen with furnaces, too

Then there are a few reasons for “cold blow” that apply to both heat pumps and furnaces. One is duct leakage. If the return side of the duct system pulls in enough cold air from unconditioned spaces (attic, crawl space, garage…), the entering air temperature drops. That results in a lower output temperature for the heating system.

A second cause could be poorly insulated ducts in unconditioned space. The return air gets colder on its way to the heating system and the supply air gets colder after being heated.

A third cause is mixing outdoor air for ventilation into the system. When it’s really cold outdoors, this can decrease the supply air temperature of both heat pumps and furnaces.

And a fourth cause here could be setting the thermostat to keep the blower running all the time, even when the system isn’t heating the air that passes through it.

Don’t blame the heat pump

My 1961 house gets nice and warm with my heat pump that produces 105 °F air. I took that photo on a chilly evening when the outdoor air temperature was 32 °F. At the same time, our ductless unit in the sunroom was cranking out 98 °F air. And the house felt nice and toasty because we were getting plenty of BTUs.

Yes, the supply air from a heat pump is cooler than that from a furnace. Yes, the heat pump stops heating during the defrost cycle. But those aren’t a problem if the system doesn’t blow air on people. As long as the heat pump is sized properly and has auxiliary heat if necessary, it shouldn’t be the cause of comfort problems.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can subscribe to Energy Vanguard’s weekly newsletter and follow him on LinkedIn.

Related Articles

Heat Pumps, Auxiliary Heat, and Resilience

The Basic Principles of Duct Design, Part 1

Converting Heating and Cooling Loads to Air Flow – The Physics

My Undersized Heat Pump in an Arctic Blast

Comments are welcome and moderated. Your comment will appear below after approval.

I noticed my Mitsubishi mini splits put out very hot air sometimes. I also noticed that they choose to put out warm air even if they are going over the set point. I think the engineers decided to err on the side of warm air coming out vs colder air and lower compressor speed

Aaron: It’s not always hot or warm air coming out of your Mitsubishi unit. The blower runs continuously, even when the compressor turns off, so at those times, it’s sending room temperature air out of the vents.

When my compressor shuts off in heating mode the fan stops. In cooling mode, the fan keeps running

OK, I have to apologize on this one. You are right. It goes down to a super low fan speed when the compressor shuts off in heating mode,

UnfortunTely Allison, you are mistaken on the Mitsubishi Mini Split sequence of operation.

Some heat pumps work with a constant speed compressor, but the Mitsubishi systems use an inverter operated variable speed compressor that is intended to modulate the compressor to maintain constant operation at a lower level, which actually will blow warm air constantly. When properly sized It will in fact operate past the control setpoint before it will shut off. This results in a system that will vary the discharge air temperature in relation to the difference between room air temperature and setpoint. In colder outside temperatures, it is not unusual to see supply air temperatures above 110 Deg.F. which is close to a high efficiency gas furnace.

When I moved into my 1966 home in CZ2, the furnace put out blazing hot air. Consequently, it ran for only very short cycles.

After I replaced the furnace with a 2-stage heat pump, the supply air feels barely warm or even the same temperature as the rest of the indoor air. Consequently, it runs for much longer cycles on the compressor’s first stage.

The heat pump strategy results in much better temperature consistency throughout the home with virtually no drafty or cold spots. It also results in noticeably lower temperature swings between cycles. And it also results in far better air cleaning because the central return’s filter is processing many more cubic feet of air.

I definitely prefer the slow-and-steady heat pump over the old blazing furnace.

+1 I have a new construction home that is tight (ACH50 of 1.7) and well insulated with variable speed HP. I have the very same experience as Ken…long run cycles at lower blower speeds provides a very consistent temperature and feeling of comfort even when >20F. As I prepare to move from our older (poorly insulated) home w a gas furnace, I am amazed at the improved comfort of the new home…and this w the thermostat a full 3 degrees lower temp setting!!! The improvement is very evident.

Tim: Yeah, another benefit you’re experiencing is from the mean radiant temperature of your walls, windows, floors, and ceilings being closer to the indoor air temperature. A good building enclosure helps a lot!

Ken: Yeah, I didn’t really go into the benefits of having lower temperature air, but you’ve stated them pretty clearly.

Very good explanation. I agree placement of registers very important. Caution needed when changing to heat system from fossil fuel to heat pump.

We see that oil furnaces and existing duct system don’t alway support a heat pump system without modifications.

Last thought “Never assume that the last heating contractor sized the unit properly.

Heat loss – Heat gain – ducting – air changes”

All these issues need to be considered on every installation!

Keep up the great work!

Daniel

Hi Allison, another great article. For that photo showing 105 deg. F at a supply register, what was the indoor temperature? Are you getting 30-35 deg. increase across-the-coil? Or was that a supply temp. with strip contribution?

Bob: Good questions. The indoor temperature was probably ~71 °F at the time, maybe 72 °F. We don’t have any auxiliary heat, so this is all compressor heat.

So here’s a real world example I have a 4-ton heat pump that makes hot air sure it does is it as hot as natural gas no it rains is probably around 1:10 range on a good day and when I say good day I mean warm air outdoor when that outside of your temperature drops to about 30° or lower I’m looking at it the 90° range that’s without changing the CFM now the bad news. My fortune heat pump system will pull at least 5,000 Watts on a moderately cold day on a very cold day and could pull as much as 6,000 that includes the fan here in the Northeast that’s 35 cents per kilowatt so honestly speaking it’s not cheap..

Thank you for that explanation. Now I understand why a duct system that is either barely adequate or even inadequate design for the furnace becomes significantly less adequate for a heat pump switchover! That makes perfect sense now.

Mike: Yeah, if you have a right-sized furnace with right-sized ducts (uncommon) or an oversized furnace with undersized ducts (most houses), doubling the air flow rate means the existing ducts may not be suitable. But doing some retrofit work to lower the loads can reduce the system size needed and thus the required air flow.

I know you have referenced loss of HP efficiency with falling outdoor temperatures in previous articles, and several comments also have acknowledged that relationship.

I don’t know if it’s an industry push or a ‘global warming’ effort, but I definitely see advocacy for HP’s as a magic bullet for cutting heating & cooling costs while simultaneously saving the planet. I can only urge caution, especially for owners of older homes doing retrofits.

Of course it’s a massively complicated calculation when a property owner asks if a HP will save money vs a furnace/AC combo. I just wish the industry would be more up-front about operating costs in cold climates (and very hot climates, but that’s another discussion). You often see break-even outdoor temps quoted somewhere in the 40°F range, but that value changes a lot depending on indoor and outdoor equipment locations, existing ducting design (or lack thereof), home insulation characteristics, and unit designs.

I regularly hear complaints like “I shelled out $xxx for this new heat pump, and I’m not saving any money on winter heating bills. On top of that, my house feels drafty, especially at night.”

As I said, I can only urge caution. A HP may be a poor choice, or a brilliant decision, but homeowners need to get realistic information from somebody before making that decision.

Ed: Good points. I haven’t yet written about the what happens to utility costs when you switch fuels, but it’s on my list to cover soon. In some cases, it’s a no-brainer to switch to a heat pump because the savings start immediately. I’m thinking of homeowners who currently heat with oil or propane. In others, going to a heat pump can increase utility costs. And in some cases it can add a lot. That would be true for an area with low gas costs, moderate to high electricity costs, and a heat pump that uses too much strip heat.

Hello Allison, Thanks for the educational article. I had thought that it was common knowledge that air to air heat pumps deliver colder air than furnaces and that one must compensate with larger volumes. However, I can’t help but see this as a bug and not a feature, making these devices less appropriate for retrofits to existing ductwork. To be pejorative, I don’t think that blowing larger volumes of cold air around a building sounds very comfortable. 😉 I suppose it must be an HVAC installers nightmare, and not anything I want to grapple with so I stay away from it my work.

As a young man entering the renewable energy field 40 years ago, I had my nose, (necessarily) rubbed in energy and environmental economics which is something that I now much plague my colleagues with, so my apologies.

In my area heat pumps are just barely competitive with condensing propane appliances or and ~15% more competitive with fuel oil with respect to “fuel” costs, but not enough to produce a payback on the increased investment. For condensing natural gas fired appliances produce heat at 3x – 4x the cost of operating electric heat pumps so there is a negative payback on the heat pump making it an expense rather than an investment.

I try to maintain some professional ethics around what I do and I can’t in my right conscience sell a homeowner on and expensive retrofit that not only shows a negative payback but I know is environmentally irresponsible as well.

When I built, part of the reason I wanted a sealed crawl space instead of a slab was to have the supply diffusers on the floor, and be able to stand over a supply diffuser in the winter to warm up. My builder, who really wanted to pour a slab, kept insisting that with a heat pump, the air coming out of the supply ducts would be “room temperature or so close to it that the difference is not noticeable.” Having done some research I was confident that was not accurate, and I wanted the crawl space for other reasons also (what I really wanted was a basement but the lot was not suitable for that). So I got a crawl space with the ducted mini split units in the crawl space.

I am very happy to report that when I come into the house on a very cold day, or if I’m just chilly for some reason, I can stand over a floor diffuser and DEFINITELY feel very warm air that instantly takes the chill off. I can hang towels over a floor diffuser and they get noticeably warm.

My ducted mini split fan quietly runs 24/7/365, makes the house very comfortable and definitely puts out air warm enough to notice the difference between the room temp air, in a very very nice way!

Your comment about furnaces and ducts commonly being sized incorrectly caught my attention. We are building a new house 2 hrs north of Toronto. We were hopeful of using only a mini split system to facilitate-20c or -30c temps that we sometimes get. The heat pump stopping during defrost cycle, becoming less efficient or stopping as it approaches -20c have caused us to look at plan B. This would be a central heat pump, run through a propane furnace. The furnace would only fire up when the heat pump could not reach the set temperature. A heat loss/gain calculation and duct layout is being done now and thanks to you we will be looking for not blowing air on people.

How can we best insure we end up with the proper sized heat pump, furnace and ducting given the comments about improper sizing being common?

Many thanks.

Paul,

Step one is for a proper Manual J to be completed. I would suggest attempting to do one yourself if you feel up to it. Google for CoolCalc. It is involved but one can learn how to do a credible Manual J with CoolCalc. The value of doing one yourself is that you have something to compare with the HVAC contractor. If yours agrees then step one is hopefully good. If it disagrees enough to affect equipment sizing then you need to have a discussion with the HVAC contractor or builder. They may or may not be open to that discussion. Manual D duct design is pretty complicated for most people and unfortunately even for many HVAC contractors. These days an HVAC contractor should be using WrightSoft or similar software for their Manuals J, S and D and be willing to share the reports with you. ACCA publishes some checklists for building inspectors that homeowners could use just as well to do a reasonability check on the HVAC contractor’s plans. You can also ask them the design total CFM per unit and crosscheck duct capacity against their plans, possibly with a ductulator. Its a huge red flag if the HVAC contractor is not using approved design software for both the Manual J and D and further indicates using “proprietary methods” or “rules of thumb”.

The reason to doublecheck the HVAC contractor is simple. Too many still use the old rules of thumb methods. HVAC system design is very complicated and many companies avoid utilizing the available software design tools and requisite training. I have experience in this area so I double checked my builder’s HVAC contractor and found their design to be massively wrong. The short story is that the furnace was sized at 80k btuh when only a 60k btuh unit was required and the ductwork was undersized even for the correct furnace let alone the oversized one. They did not follow manufacturer instructions properly for installation of the furnace, humidifier or media filter. On top of it all, the furnace high limit tripped constantly due to all the design deficiencies and NOBODY noticed that because they clearly failed to run anything even vaguely resembling a commissioning process. After numerous significant discussions with the build I at least got the furnace replaced with the proper size under warranty. I am dealing with the remaining duct issues myself.

You are paying for a new house with a new HVAC system. You should get what you are paying for with a properly designed and functioning HVAC system.

I am a 313a and gas fitter (35 years)

This year I installed a 28.1 seer mini split in my own home.

I also installed a carrier 15 seer heat pump in my best friend’s furnace.

I have saved a fortune. My friend on the other hand has not.

Super efficient whole house units are extremely expensive even at the dealer level. The new mini splits are super performers. But a compromise in comfort.

I live in northern Ontario Canada and mine held its own at below -25 Celsius.

I get a kick out of the first cardinal sin of design…. “Don’t blow air on people!” And then the first thing after HVAC design is then said that ceiling fans are a big part of the system as well.. Doh….

I like having that cool air blow on me in the summer and most people do that live here in Crematoria(Texas). So weather it’s the vent itself or the fan it’s a moot point. And in the winter how many people don’t often scout out that spot where they can stand and have that hot air blowing on them.

Now when it comes to running your ac in reverse to heat your house we all know the temps are typically not as hot as a proper furnace and having that cooler air blow directly on people is not a good idea.

My issue with heat pumps is that like others have mentioned they are often not any cheaper to run than a gas furnace. The only way I can see a heat pump as being a great choice is if you also produce your own electricity barring that it’s case dependent. We are talking central air systems as those are the standard in N america. Their efficiency is really pretty poor for units that the average homeowner can afford. If you are in a cold climate or anywhere that has cold snaps I would NOT rely on a heat pump as my only source of heat. And never rely on one heating or cooling system for your house. Always have a backup for at least an area of your house.

But the memory of heat pumps from the recent past has still put a large number of people against them. For many years they were difficult to install, high failure rate, not really cost efficient, couldn’t heat much below 40* and they had heat at the vents that was hard to tell if it was working. That is not the case anymore other than I’m not impressed with typical split system efficency still.

Then when you bring in the minisplit systems which are not well received in the US as most don’t want that big thing hanging on the wall. Those will always blow on people. Just how it is with the typical ones and most people aren’t going to complain about them because their vent temps are pretty high and low for cooling.

I’m watching what’s going on over in England with their push for heat pumps and loads of problems there which start with their overcomplicated hot water radiator systems. Lots of unhappy and cold people there.

And the other heat pumps out there like PTACs and package units they really don’t make sense. I’d really like to see allot more insulation and a decent bump in efficency of package units as they have allot of good uses since it’s all outside in one box and easy to swap out. Not hard to do but they would be physically larger.